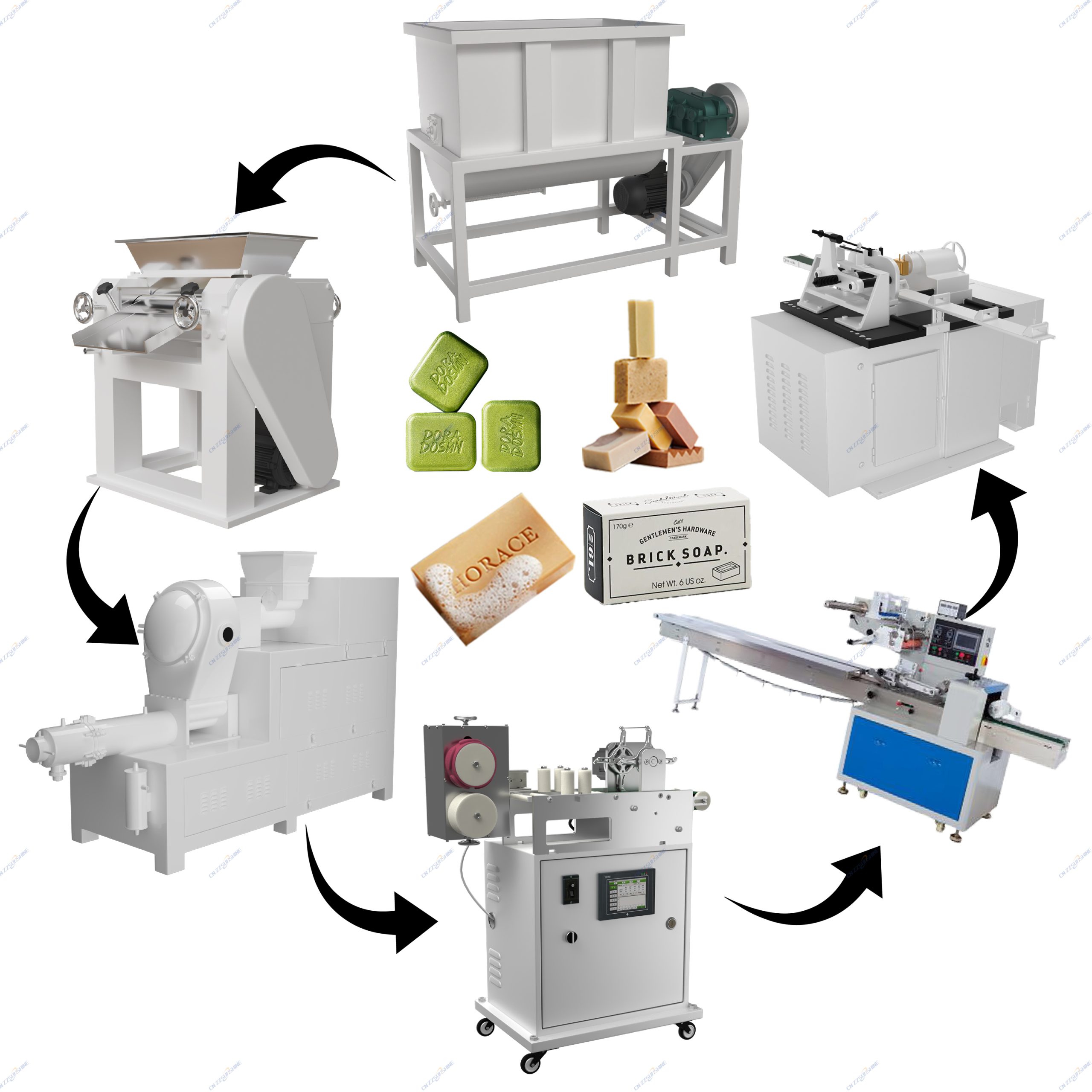

Demanding consistent quality and high output in soap manufacturing requires precision engineering. Modern automatic soap production lines integrate specialized equipment, replacing labor-intensive manual processes with reliable, efficient automation. This integrated approach is essential for producing both laundry bars and premium toilet soaps at scale.

The core process begins with thorough mixing. Industrial mixers for chemical processing handle the amalgamation of oils, fats, caustics, and additives, ensuring a homogenous soap base critical for final bar quality and performance. This initial stage sets the foundation for the entire production line.

Following mixing, the soap base undergoes refining and extrusion. A twin-screw vacuum plodder machine is central here. It compresses the soap mass, removing air pockets under vacuum to create a dense, uniform grain essential for a high-quality bar. This plodding stage significantly impacts the final soap’s texture, lather, and durability. Lines designed specifically for laundry bar soap production often emphasize robust plodding to achieve the required hardness.

The extruded soap log then moves to shaping and cutting. Custom soap cutting machines, often PLC-controlled electric washing soap cutters, provide precise, hygienic sizing. These cutters deliver consistent bar weights and clean edges, minimizing waste. For bath soap making machines targeting the cosmetics sector, options include three-roller mills for cosmetics to refine pigments or additives before extrusion, and specialized toilet soap finishing line equipment for stamping, polishing, and intricate moulding.

Integrating an industrial chiller for machinery is often vital. Factory price industrial chillers efficiently cool cutting blades, hydraulic systems, and potentially the plodder barrel, maintaining optimal operating temperatures for consistent results and extended equipment life.

The culmination is efficient packaging. Automatic packing machines for food-grade materials handle wrapping, boxing, and palletizing the finished bars, completing the automated workflow. Leading OEM three roller grinding mill manufacturers and automatic soap production line suppliers, particularly experienced China feed processing machine suppliers diversifying into cosmetics, offer configurable solutions. Whether you need a compact beauty soap making line or a full-scale laundry soap making line, selecting an integrated system with a high-efficiency vacuum plodder, precise cutter, and reliable mixer delivers significant gains in productivity, consistency, and cost control.