The All-In-One Solution for Small-Scale Soap Manufacturing Excellence

For businesses entering or scaling within the competitive soap manufacturing market, finding efficient, cost-effective, and reliable machinery is paramount. The challenge often lies in sourcing equipment that delivers high-quality results without demanding excessive space or capital investment. This is where the concept of an automatic complete toilet soap finishing price small soap all-in-one machine shines, offering a streamlined solution specifically designed for manufacturers seeking agility and quality.

Manufacturers specializing in laundry soap making machines and toilet soap finishing lines understand the diverse needs of their clients. They recognize that not every operation requires massive laundry bar soap production lines or expansive bath soap making machine setups. For smaller enterprises, startups, or businesses producing niche products like beauty soap, compact and integrated solutions are key.

The Power of Integration: Core Components

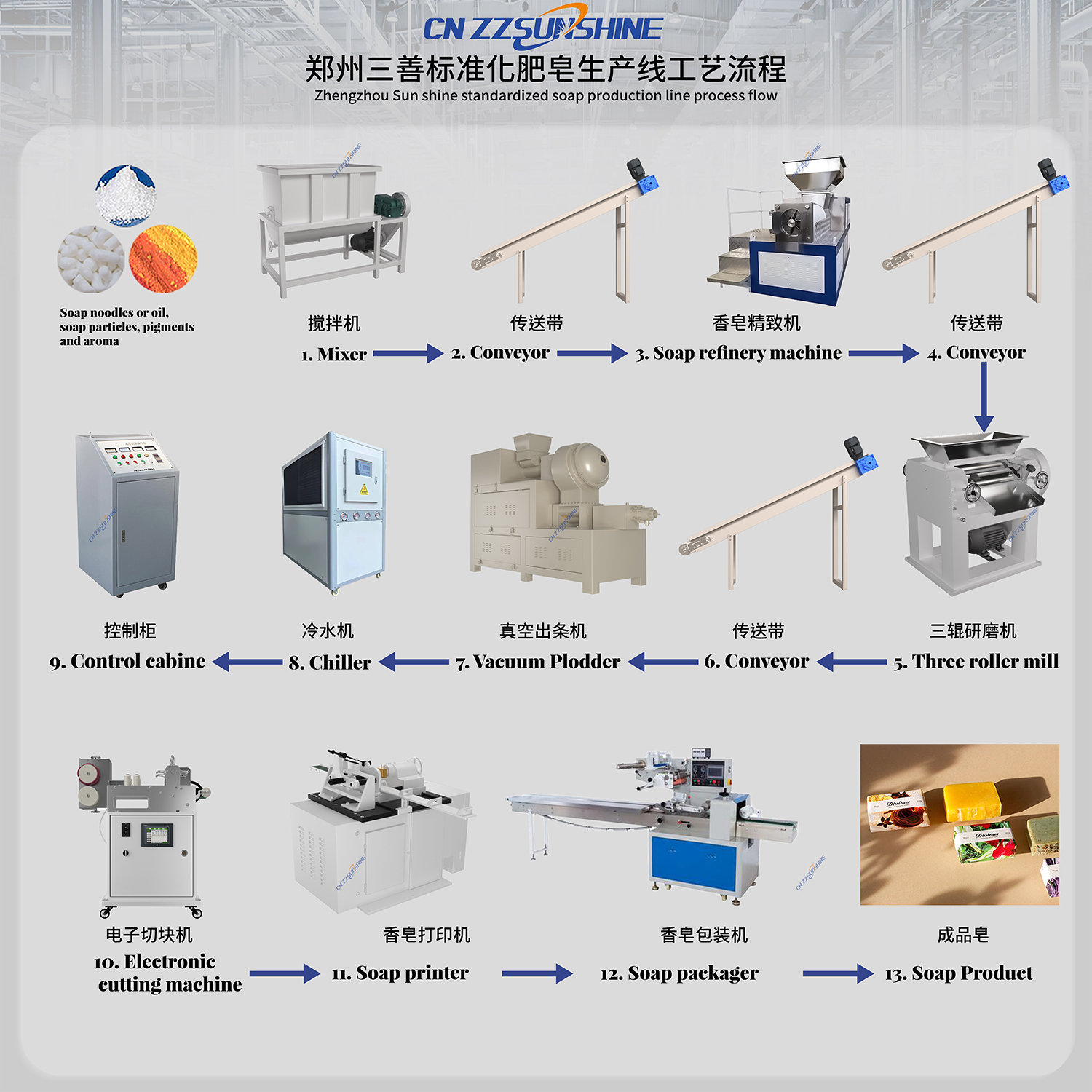

A true small soap all-in-one machine integrates critical stages of the soap making production line into a more manageable footprint. Imagine churning out consistent, high-quality bars with a compact setup that incorporates:

Efficient Mixing: A robust soap mixer or mixing machine ensures homogeneous blending of raw materials, forming the perfect base.

Precision Refining: Integrating technology like an OEM three roller grinding mill facilitates the refinement process, crucial for achieving the desired texture and smoothness in both toilet soap and laundry soap.

Vacuum Plodding: A vacuum plodder component within the unit is vital. It removes air pockets, compacts the soap mass, and extrudes a continuous, dense soap noodle or log, ready for shaping. This step is fundamental for producing durable, long-lasting bars.

Accurate Cutting: Whether using an automatic block cutter machine, a pneumatic cutting machine, or an electronic cutting machine, the system precisely sections the extruded soap log into individual blocks. This ensures uniformity and minimizes waste.

Streamlined Finishing: The automatic complete toilet soap finishing aspect covers stamping and potentially basic packaging. An integrated soap stamping machine imparts brand identity, while options like a semi-automatic printer or film packaging machine might handle wrapping, depending on the machine’s sophistication. This creates a near-complete automatic soap production line in miniature.

Why Choose a Compact, All-In-One Solution?

Investing in a well-designed small soap all-in-one machine from a reputable laundry soap making machine manufacturer offers significant advantages:

Cost Efficiency: Lower initial investment compared to sprawling automatic soap production lines. Reduced operational costs (space, energy, labor).

Space Optimization: Ideal for limited production areas or businesses scaling up gradually.

Production Flexibility: Capable of handling various soap types – from laundry soap to toilet soap and specialty beauty soap. Quick changeovers between products.

Quality Control: Integrated processes ensure consistency and high-quality output, leveraging technologies like the vacuum plodder and precise cutting machine.

Reduced Complexity: Simplified operation and maintenance compared to managing multiple standalone machines like a dedicated soap plodder machine for bar soap or a separate custom soap cutting machine.

Partnering with the Right Manufacturer

Selecting a manufacturer with expertise in both laundry soap making lines and toilet soap finishing lines is crucial. They should offer not just the automatic soap production line equipment, but also the support, customization options (like OEM services), and understanding of the specific challenges faced by smaller producers. Look for providers who can tailor their mini soap production line solutions to your exact throughput requirements and product specifications.

Conclusion

For ambitious soap makers prioritizing efficiency, quality, and smart investment, the automatic complete toilet soap finishing price small soap all-in-one machine represents a compelling solution. By consolidating essential processes – mixing, refining, plodding, cutting, stamping – into a single, optimized unit, manufacturers gain the capability to produce professional-grade soap bars competitively. Partnering with an experienced laundry soap making machine manufacturer ensures access to reliable technology designed to empower small-scale production success. Explore integrated options today and elevate your soap manufacturing capabilities.