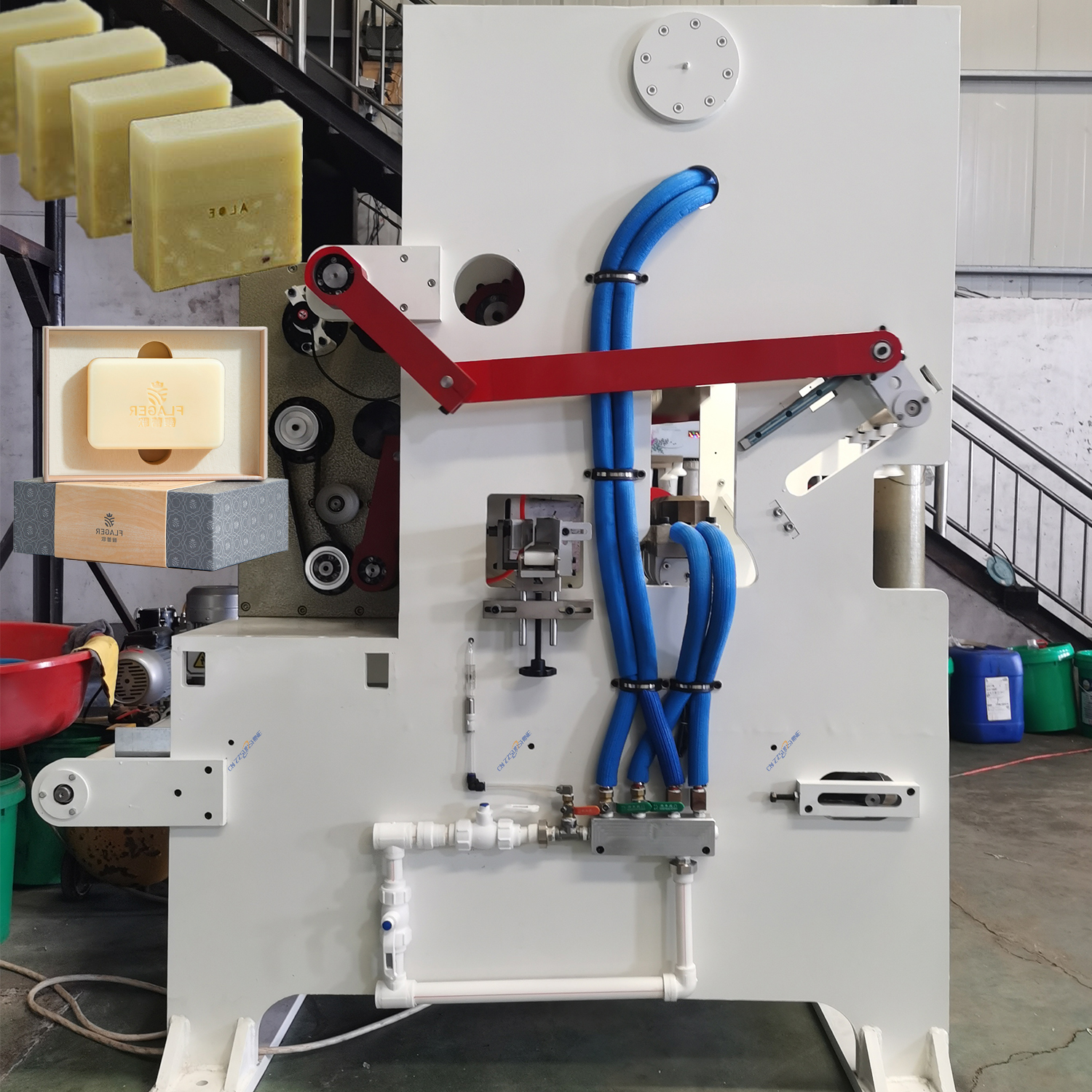

Efficient and high-quality bar soap manufacturing hinges on the performance of core extrusion equipment. The **vacuum plodder machine** stands as the critical component within any modern **laundry soap making line** or **toilet soap finishing line**. Its primary function is to transform mixed soap noodles into a dense, homogeneous, and completely de-aerated log ready for cutting and stamping.

Unlike simple **soap mixer** units that blend ingredients, the **vacuum plodder** subjects the soap mass to intense pressure within its barrel while simultaneously removing all trapped air pockets under vacuum. This dual action is essential for achieving the desired **homogeneous texture** and **consistent density** required in the final bar. Air bubbles are eliminated, preventing common defects like cracking, crumbling, or uneven dissolution during use. The resulting extruded log possesses significantly **improved plasticity**, making it far easier for downstream **automatic soap cutting machines** or **electric washing soap cutters** to achieve precise, clean cuts with minimal waste. This directly impacts the efficiency of the entire **automatic soap production line**.

Integrating a well-engineered **soap plodder machine** into your **laundry bar soap production line** or **bath soap making machine** setup offers substantial advantages. Key benefits include **enhanced product durability**, **superior lathering properties**, and a noticeably smoother finish on the final bar. The **de-aeration process** facilitated by the vacuum system is non-negotiable for producing premium-grade **bar soap**, whether for laundry, toilet, or beauty applications. Furthermore, modern plodders are designed for **continuous operation**, minimizing downtime and maximizing output within the **soap finishing line**.

Choosing the right plodder configuration – including the number of stages (single, twin, or triple) and screw design – is vital and depends on the specific soap base formulation (e.g., tallow-based vs. vegetable oil-based) and the desired production volume. Investing in a robust **vacuum plodder** is fundamental to achieving consistent quality, reducing waste, and ensuring a **streamlined production flow** in competitive soap manufacturing.