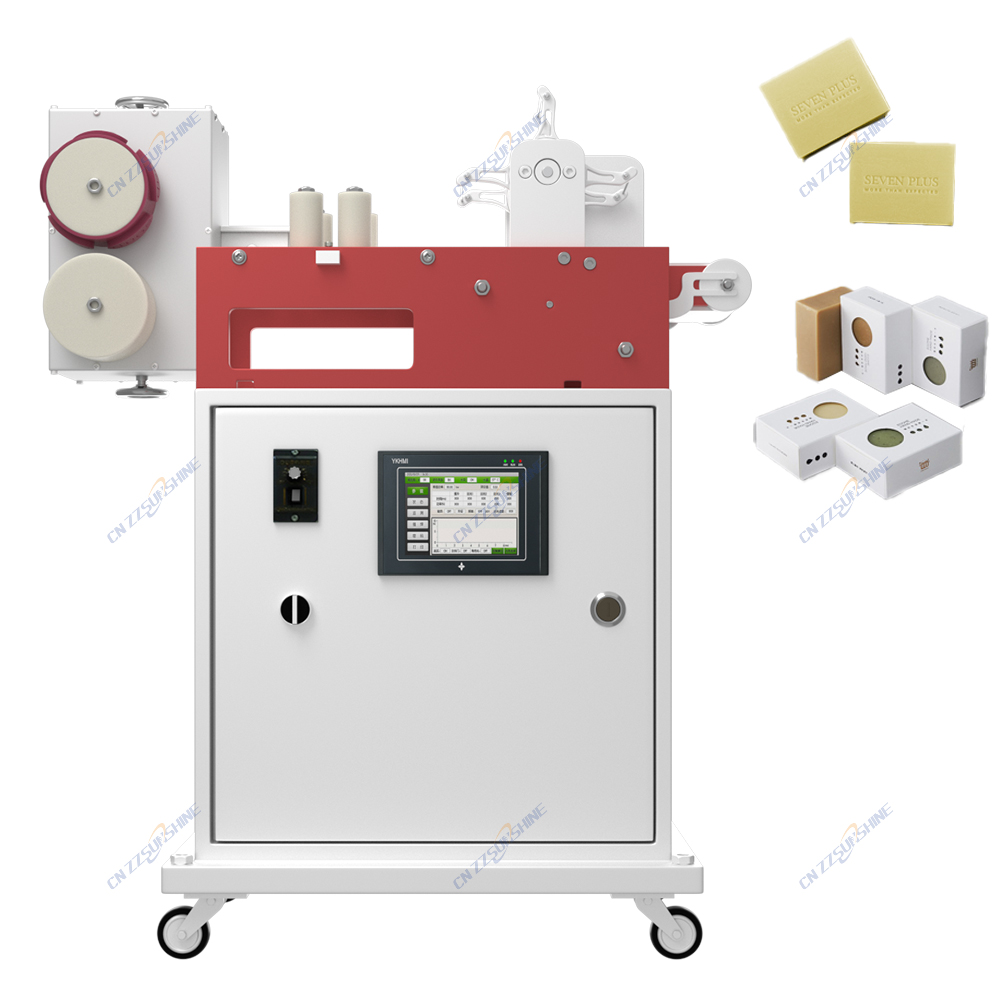

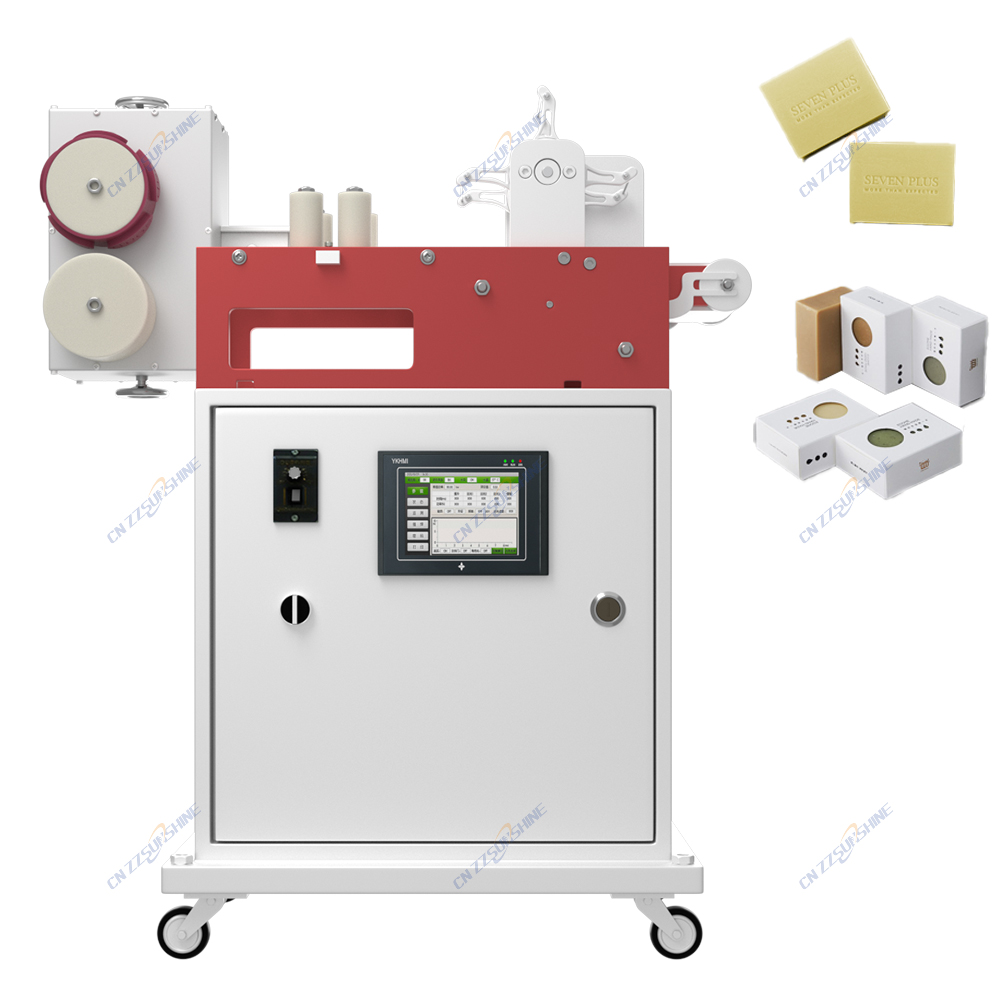

In today’s competitive soap manufacturing industry, implementing a robust soap making production line is essential for achieving consistent quality and scalability. This integrated system typically includes key components like a vacuum plodder for refining soap base, an industrial mixer for chemical processing to blend additives uniformly, and an electric washing soap cutter for precise sizing. By automating steps from mixing to cutting, such a line minimizes human error and boosts throughput—ideal for laundry bar soap production line setups or beauty soap making line applications. For instance, a vacuum plodder ensures air-free extrusion, enhancing bar soap durability, while a custom soap cutting machine allows tailored dimensions to meet diverse market demands, such as bath soap or toilet soap varieties. Moreover, incorporating an automatic soap production line with energy-efficient features reduces operational costs and supports sustainable practices. Factories can leverage OEM three roller grinding mill options for cosmetic-grade finishes or integrate a laundry soap making line with high-capacity plodders to handle large volumes. Ultimately, investing in a modern soap making machine not only optimizes resource use but also ensures compliance with hygiene standards, making it a smart choice for expanding global markets.

Innovative Soap Making Production Line for High-Efficiency Manufacturing

Innovative Soap Making Production Line for High-Efficiency Manufacturing

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!