Streamlining soap manufacturing demands precision equipment and seamless integration. Investing in a robust automatic soap production line transforms raw materials into finished bars efficiently, ensuring consistent quality and high output. The process begins with a high-shear industrial mixer for chemical processing, thoroughly blending fats, oils, alkali, and additives into a homogeneous soap base. This critical initial mixing stage directly impacts the final bar’s properties.

The refined soap base then moves to a vacuum plodder. This essential soap plodder machine compresses the mixture under vacuum, forcibly removing trapped air. This step is non-negotiable for achieving the dense, smooth, bubble-free texture expected in premium bar soap, whether for laundry or toilet applications. Modern vacuum plodders are engineered for continuous operation and minimal downtime.

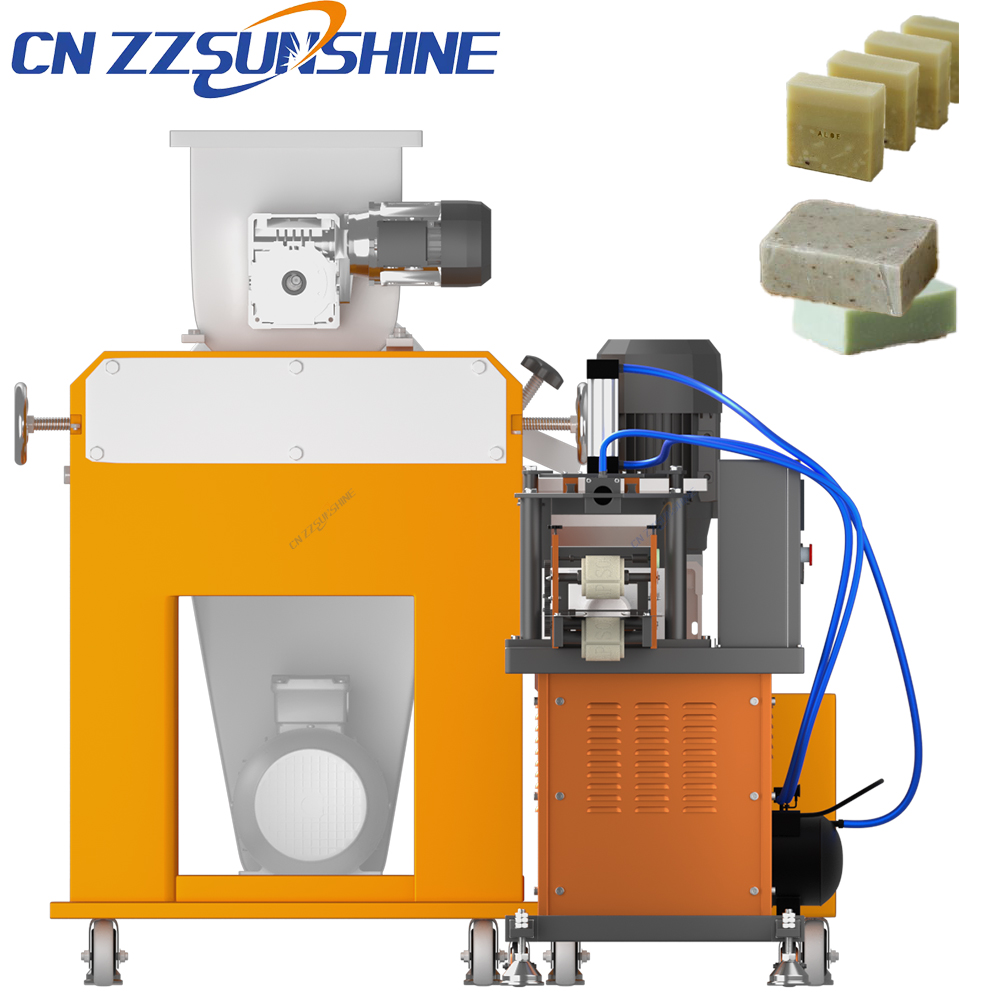

Following extrusion from the plodder, the continuous soap log enters the cutting phase. An electric washing soap cutter, or automatic block cutter machine, provides exceptional precision. These cutters utilize sharp blades and advanced feeding mechanisms to slice the log into uniform billets with minimal waste or distortion, critical for both aesthetics and packaging efficiency. For specialized requirements, a custom soap cutting machine can be integrated.

For manufacturers focusing on premium cosmetic or beauty bars, incorporating a three-roller mill for cosmetics into the line is vital. This refining mill further smoothes and homogenizes the soap base before plodding, enhancing luxurious texture and appearance, especially important for beauty soap making lines. OEM three roller grinding mill options offer flexibility for specific formulations.

The culmination is a complete laundry bar soap production line or toilet soap finishing line capable of high-volume, consistent output with minimal manual intervention. Key advantages include significant labor savings, strict hygiene control, reduced material waste, and guaranteed product uniformity. When selecting equipment, partnering with a reliable manufacturer experienced in soap making machine systems ensures optimal line configuration, from the initial soap mixer to the final cutter, maximizing your return on investment.