Running a competitive soap manufacturing operation demands precision and efficiency at every stage. Integrating a well-designed **automatic soap production line** is no longer a luxury, but a necessity for consistent quality and profitability. This encompasses everything from the initial blending to the final wrapping.

The process starts with robust **mixing machinery**. A high-shear **industrial mixer for chemical processing** ensures homogeneous blending of fats, oils, lye, and additives, forming the perfect soap base. This critical step impacts the final bar’s texture and performance. The mixed paste then undergoes refining and extrusion. Modern lines utilize a **vacuum plodder** – arguably the heart of the line – which compacts the soap under vacuum, removing air pockets and moisture to create a dense, uniform grain essential for premium **bar soap production**, whether for **laundry soap making lines** or **toilet soap finishing lines**.

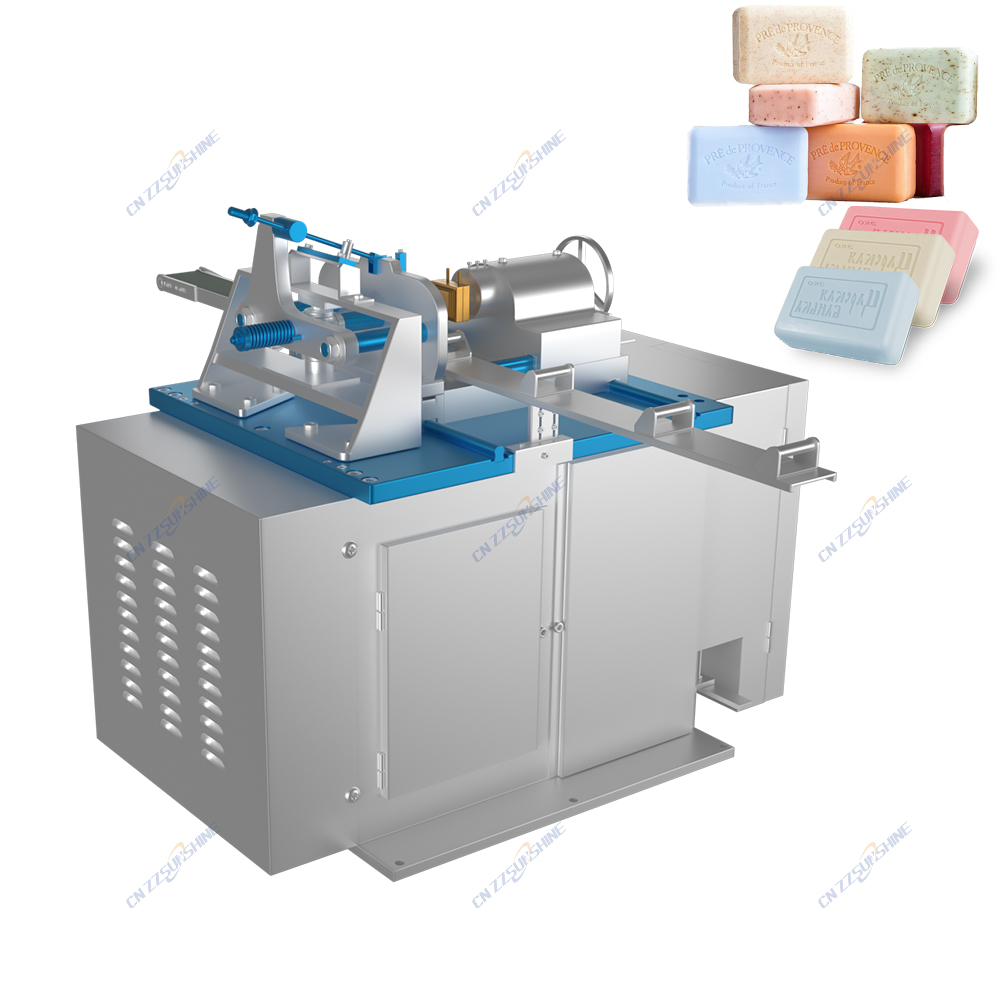

Following extrusion, the continuous soap log requires precise sizing. An **electric washing soap cutter** or a **custom soap cutting machine** delivers clean, consistent cuts with minimal waste, crucial for maintaining product uniformity and maximizing yield. For specialized applications like **beauty soap making lines**, additional finishing such as stamping or milling might be incorporated. Supporting the entire operation, a reliable **industrial chiller for machinery** is vital. It regulates temperatures during mixing and plodding, preventing overheating and ensuring optimal viscosity and process stability, directly impacting final bar quality and line uptime.

Choosing the right equipment configuration – be it a dedicated **laundry bar soap production line** or a flexible **bath soap making machine** setup – depends on your specific product range and volume targets. Partnering with experienced manufacturers, including reputable **China feed processing machine suppliers** who often diversify into soap machinery, can offer access to advanced technology and **factory price industrial chiller** units. Look for suppliers offering **OEM three roller grinding mill** options if milling additives is part of your process. Ultimately, investing in an optimized, high-performance **automatic soap production line**, featuring efficient **soap plodders**, **soap mixers**, and **cutters**, translates directly to lower operating costs, superior product consistency, and a stronger market position.