For manufacturers serious about scaling bar soap output, investing in a well-integrated soap making production line is non-negotiable. Moving beyond rudimentary setups unlocks consistent quality, significant efficiency gains, and reduced labor costs. The core of a robust line lies in specialized equipment designed for each critical stage.

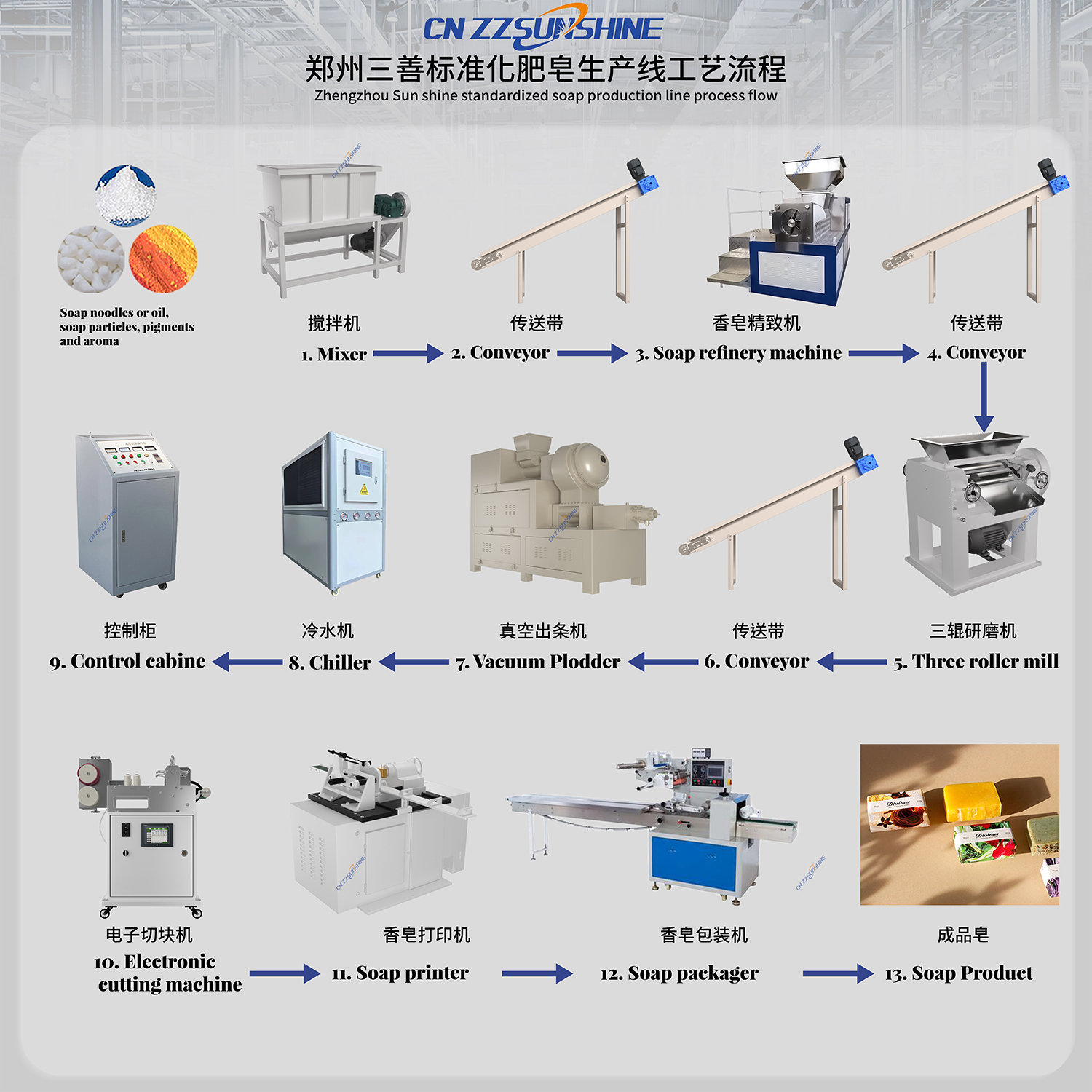

The process begins with thorough blending. A high-shear industrial mixer for chemical processing ensures fats, lye, and additives combine homogeneously, forming the perfect soap base. This stage is foundational; inconsistent mixing leads to defects downstream. Once mixed, the soap base requires refining. A three roller mill for cosmetics, often an OEM three roller grinding mill for specific viscosity needs, meticulously smoothes the paste, eliminating graininess and ensuring a luxurious texture, especially crucial for bath soap making machines and beauty soap making lines.

The refined soap then enters the extrusion phase – the heart of the line. Here, a robust soap plodder machine for bar soap, preferably a vacuum plodder, is indispensable. The vacuum plodder removes trapped air, preventing bubbles and fissures, while simultaneously compacting the soap into a dense, continuous log. This dense extrusion is vital for producing long-lasting laundry bars or premium bath products. Modern automatic soap production lines seamlessly integrate the vacuum plodder with subsequent stages.

Following extrusion, precise sizing is key. An automatic block cutter machine or a versatile custom soap cutting machine slices the extruded log into uniform blanks. For laundry bar soap production lines, heavy-duty cutters handle larger volumes, while precision electric washing soap cutters ensure clean, consistent bars for toilet soap finishing lines. Automation at this stage minimizes waste and maximizes throughput.

Finally, the cut bars proceed to finishing. A dedicated toilet soap finishing line or laundry soap making line incorporates stamping, polishing, cooling, and automated packing machine for food-grade packaging. This final stage presents the product professionally and protects it during transit.

Integrating these components – from the industrial mixer and vacuum plodder to the custom soap cutting machine and finishing equipment – creates a cohesive automatic soap production line. Partnering with experienced suppliers, potentially including a reputable China feed processing machine supplier with diversified capabilities, ensures access to reliable machinery like factory price industrial chillers for process cooling and high-efficiency support systems. The result is a streamlined laundry bar soap production line or bath soap making machine setup capable of delivering superior quality at competitive volumes.