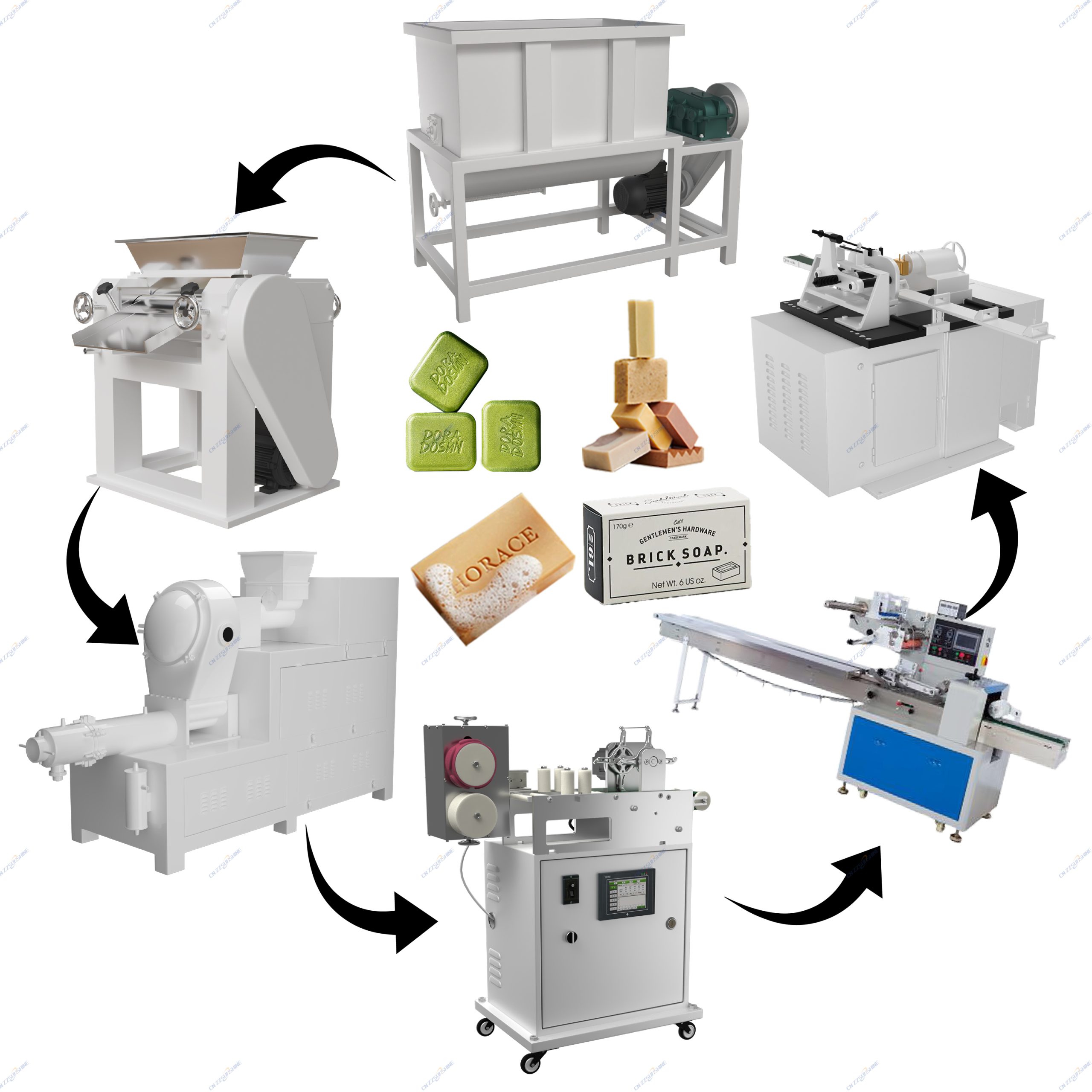

Consistent density and texture are non-negotiable in professional bar soap manufacturing. While the entire soap making production line plays a role, the vacuum plodder machine is arguably the most critical component for achieving these qualities in laundry, bath, and toilet soaps. This specialized equipment transforms mixed soap noodles into a perfectly homogenized, air-free, continuous log ready for precise cutting.

The process begins after the soap mixer combines oils, lye, additives, and sometimes rebatched materials. These soap noodles enter the vacuum plodder’s feed section. Inside a twin-worm screw configuration housed within a barrel, the soap is subjected to intense mechanical working and compression. Simultaneously, a powerful vacuum system actively removes any trapped air bubbles. This vacuum stage is essential; eliminating air prevents voids, cracks, and uneven density in the final bar soap, significantly enhancing its durability, lather quality, and visual appeal.

Modern vacuum plodders offer precise control over extrusion pressure and vacuum levels. Operators can fine-tune these settings to accommodate different soap recipes – whether formulating a hard laundry bar soap production line output or a softer, superfatted bath soap making machine product. The result exiting the plodder’s die is a dense, smooth, continuous soap log with a completely uniform composition. This uniformity is paramount for the next stage: cutting.

Whether feeding a high-speed automatic soap production line equipped with multi-wire cutters or a custom soap cutting machine for intricate shapes, the vacuum plodder ensures the log maintains perfect integrity. Without this crucial deaeration and compaction step, downstream processes like stamping and packaging become problematic, leading to waste and inconsistent final products. Integrating a well-maintained vacuum plodder into your laundry soap making line or toilet soap finishing line isn’t just an option; it’s the fundamental process guaranteeing the structural integrity and consumer appeal of premium bar soaps. The initial investment in this core technology pays dividends through superior product quality, reduced waste, and efficient bar soap production.