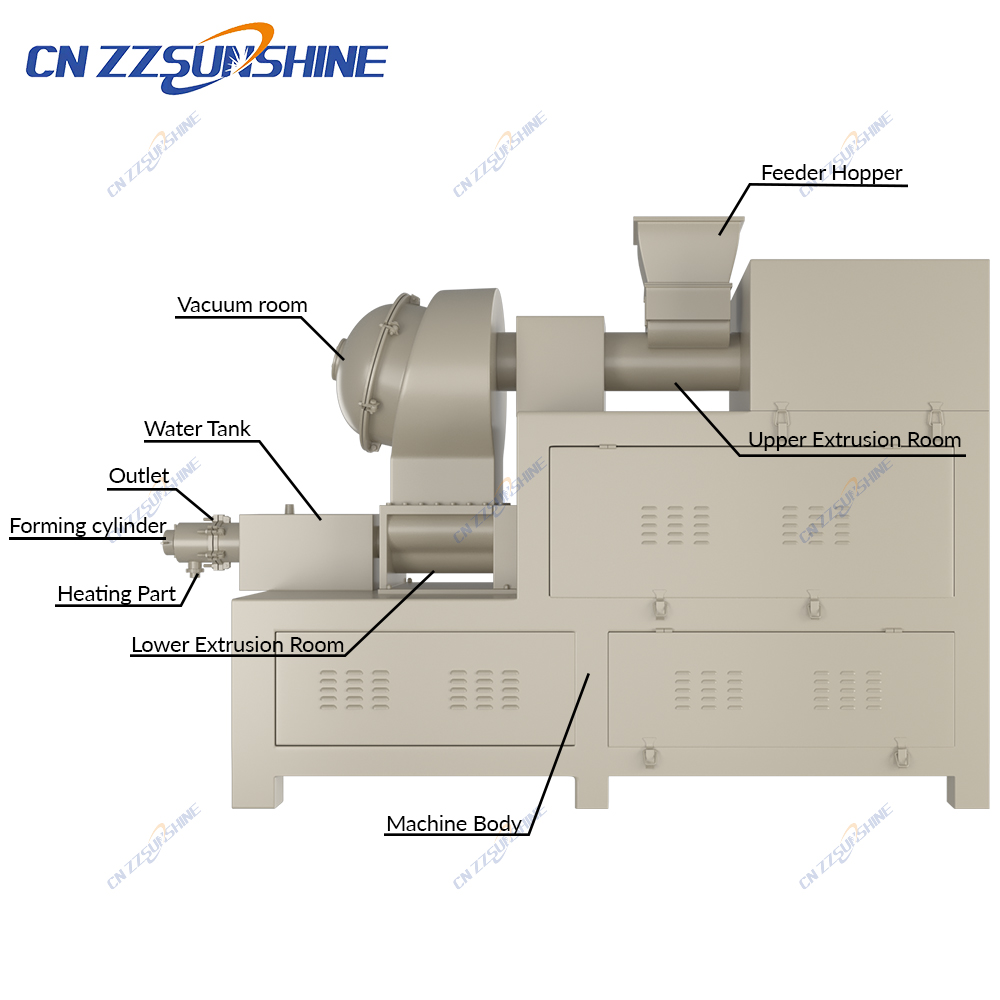

Modern bar soap manufacturing, whether for laundry or toilet applications, demands specialized equipment to achieve consistent quality and high throughput. The core of any effective laundry bar soap production line or toilet soap finishing line lies in robust processing machinery. Central to this is the soap plodder machine, specifically the vacuum plodder. This critical component compacts and extrudes the mixed soap base under vacuum, eliminating air pockets to ensure bar density, smooth texture, and prevent cracking. Precise control within the vacuum plodder is essential for final bar integrity.

Equally vital is the upstream soap mixer or industrial mixer for chemical processing. This stage is where fats, oils, alkalis, fragrances, and additives are thoroughly blended and homogenized. Efficient mixing directly impacts the uniformity and performance characteristics of the final bar soap. Downstream, the extrusion from the soap plodder requires precise cutting. This is where a custom soap cutting machine or an electric washing soap cutter comes into play. These cutters deliver clean, dimensionally accurate bars with minimal waste, adaptable to various bar sizes and shapes required for different markets, be it bath soap making machine outputs or laundry soap.

For fully integrated operations, an automatic soap production line combines these elements – mixing, refining via plodders, and cutting – into a seamless, automated workflow. This significantly reduces manual handling, boosts output, and enhances consistency. Supporting equipment, such as an industrial chiller for machinery, is often crucial for cooling extruded soap logs before cutting and for maintaining optimal temperatures in specific mixing or plodding stages, especially in warmer climates. Reliable chillers contribute directly to line stability.

Leading manufacturers, including experienced China feed processing machine suppliers diversifying into soap tech, offer comprehensive solutions. They provide not only standard soap making machine units but also focus on OEM three roller grinding mill designs for specific refining needs and tailor-made systems. The focus is always on delivering high-efficiency flour mill plant principles adapted to soap: reliability, energy efficiency, and low maintenance, ensuring competitive factory price industrial chiller integration and overall line cost-effectiveness. Investing in the right core machinery – the mixer, the plodder, and the cutter – is fundamental for building a profitable and competitive bar soap operation.