For businesses scaling up soap production, transitioning from manual batches to a fully integrated automatic soap production line is the key to unlocking efficiency, consistency, and profitability. This turnkey solution seamlessly combines essential machinery to handle every stage, from raw material preparation to finished bar packaging, minimizing labor costs and maximizing output.

The core of any high-output laundry soap making line or toilet soap finishing line lies in robust mixing and refining. An industrial mixer for chemical processing ensures the precise blending of fats, oils, alkalis, and additives into a homogeneous soap base. This mixture is then refined to achieve the desired smoothness and consistency, often utilizing specialized equipment like a three roller mill for cosmetics-grade pastes or finer toilet soaps. Consistent mixing is critical for final product quality.

Following refining, the soap base moves to the heart of the line: the vacuum plodder. This sophisticated soap plodder machine for bar soap performs two vital functions under vacuum conditions. First, it removes trapped air, preventing unsightly bubbles and ensuring a denser, longer-lasting bar. Second, it extrudes the soap through a die, forming a continuous, solid log with uniform texture and density essential for both laundry bar soap production and premium bath soap making machines. The vacuum plodder stage significantly impacts the final bar’s quality and feel.

The continuous soap log then proceeds to cutting. Here, an automatic block cutter machine or a specialized custom soap cutting machine precisely slices the log into individual bar-sized blocks. Modern lines often incorporate electric washing soap cutter systems for their precision and hygiene, crucial for meeting stringent quality standards in beauty soap making lines. Accuracy at this stage minimizes waste and ensures uniform bar weights.

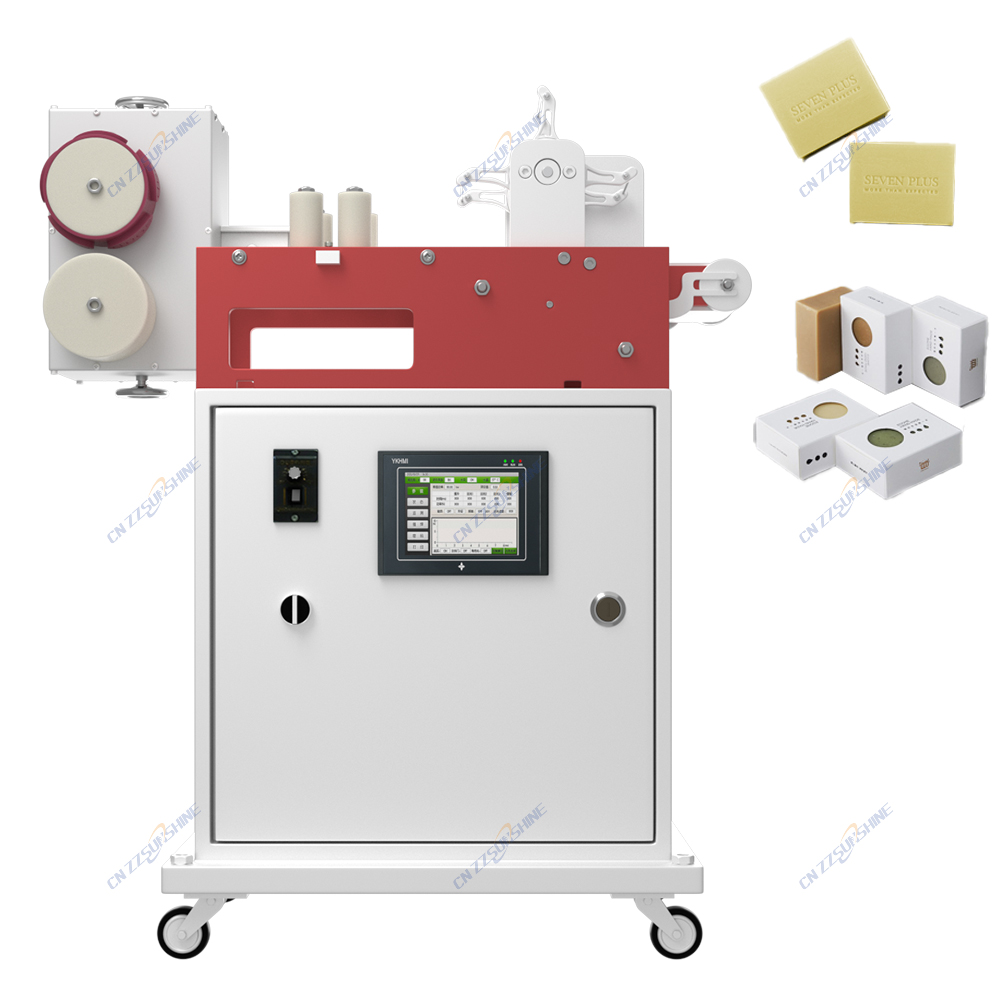

Finally, the cut bars enter the finishing stage. For toilet soap finishing lines, this typically includes stamping, embossing, cooling, and wrapping. A reliable automatic packing machine for food-grade products is often integrated to handle the final wrapping and boxing efficiently, completing the automated cycle.

Investing in a well-designed automatic soap production line, incorporating a high-quality soap plodder, efficient mixer, and precise cutter, transforms manufacturing. It delivers the high-volume capacity, consistent quality, and operational reliability demanded by competitive markets, whether producing robust laundry bars or luxurious bath soaps. Partnering with a reliable manufacturer ensures optimal line configuration for your specific output goals and product types.