Establishing an efficient laundry soap making line demands precision-engineered equipment. Understanding core machinery functions is crucial for maximizing output, ensuring consistent quality, and minimizing costly downtime. Let’s examine the critical components driving a modern laundry bar soap production line.

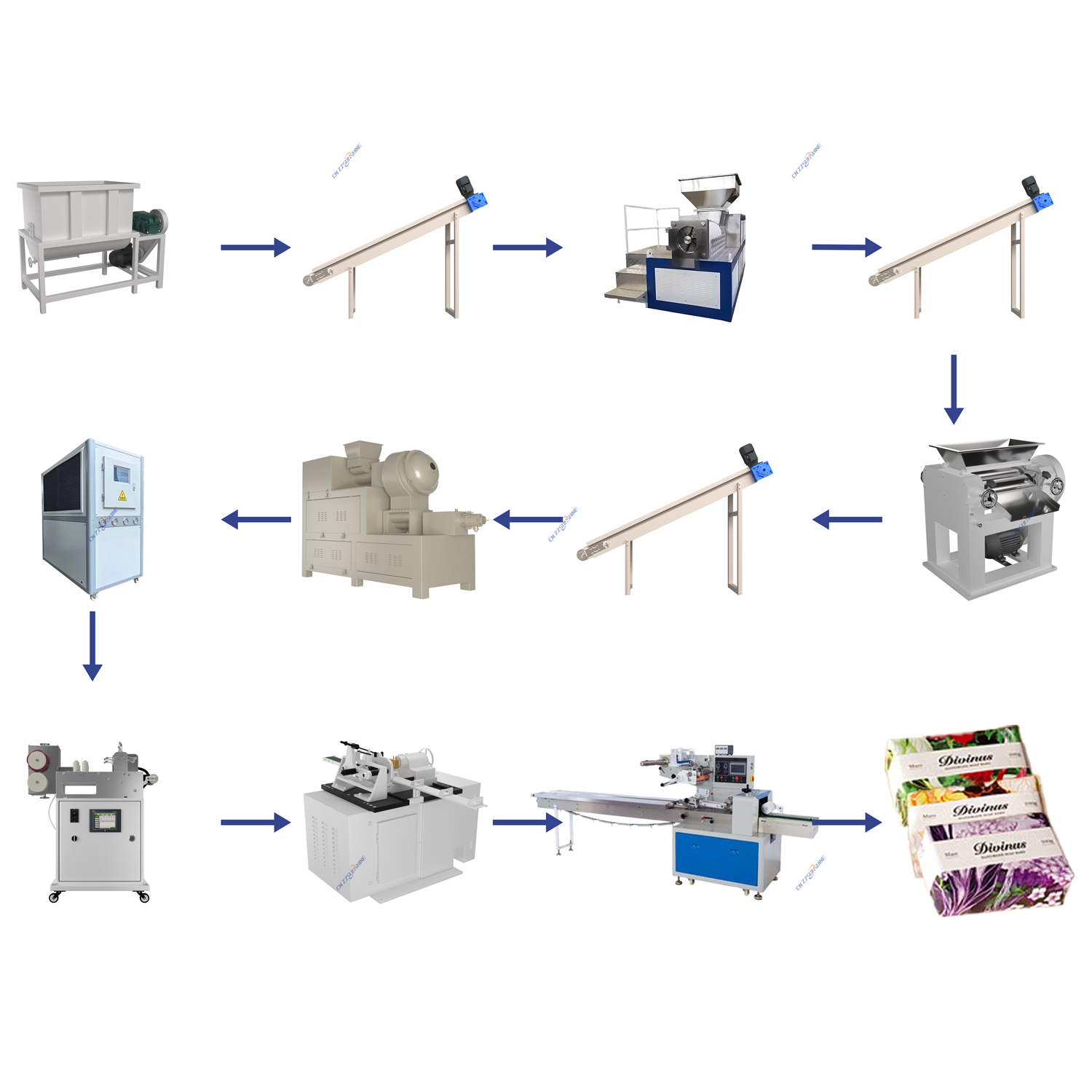

The process begins with robust **soap mixing machines**. Industrial mixers for chemical processing must handle dense soap paste, uniformly incorporating additives like fragrances, dyes, and builders. Following mixing, the homogeneous paste undergoes refining and extrusion. This is where the **soap plodder machine** becomes indispensable. Specifically, a high-quality **vacuum plodder** removes air pockets under vacuum, significantly enhancing the final bar’s density, smoothness, and lathering properties. This step is vital for producing premium laundry bars that resist crumbling and dissolve effectively.

After extrusion through the **soap plodder**, the continuous soap log requires precise cutting. **Automatic soap cutting machines**, often featuring **electric washing soap cutter** technology, ensure bars are sliced to exact dimensions with clean edges. For operations needing flexibility across different bar weights or shapes, investing in a **custom soap cutting machine** proves advantageous. These cutters integrate seamlessly into the **automatic soap production line**, maintaining high-speed throughput without compromising accuracy.

Beyond the core soap-specific units, auxiliary equipment plays a vital support role. Reliable **industrial chillers for machinery** are essential for cooling extruded soap logs before cutting, preventing deformation, and ensuring dimensional stability. Efficient **automatic packing machines for food** (adapted for soap) handle the final wrapping and boxing, completing the streamlined **toilet soap finishing line** or **laundry soap making line**.

Choosing the right partner is paramount. Reputable suppliers offer not just individual machines like the **soap mixer** or **cutter**, but the expertise to integrate a complete, high-performance **bath soap making machine** line or **beauty soap making line**. Look for providers with proven experience in **OEM three roller grinding mill** applications (often used in niche cosmetic soap bases) and a track record in delivering turnkey solutions. The goal is a cohesive **soap making production line** where every component, from the initial **mixing machine** to the final packer, works in perfect harmony to deliver factory efficiency and product excellence.