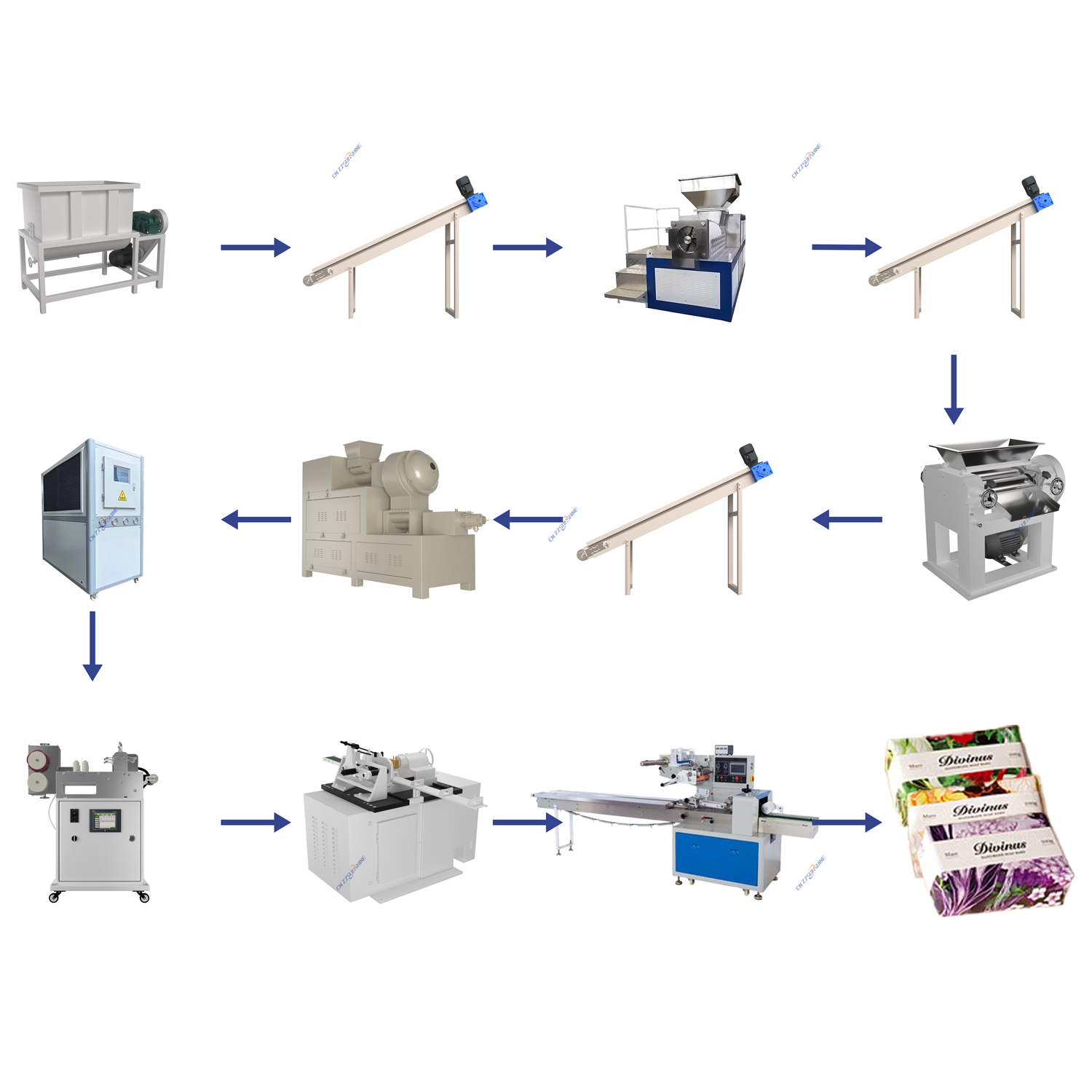

Modern soap manufacturing demands efficiency, consistency, and scalability. Integrating a fully **automatic soap production line** is the definitive solution for factories aiming to elevate output while maintaining stringent quality control. This seamless system integrates critical components like the **soap mixer**, **soap plodder machine**, and **custom soap cutting machine** into one cohesive, high-throughput operation.

The process initiates within the **industrial mixer for chemical processing**, where precise blending of fats, oils, lye, and additives occurs under controlled conditions. This foundational mixing stage is crucial for achieving uniform saponification and consistent base quality. The mixed soap mass then feeds into a **vacuum plodder**, a core element of any **laundry soap making line** or **toilet soap finishing line**. This specialized extruder removes air pockets under vacuum, compresses the soap, and forms a continuous, dense log with a homogeneous texture essential for premium bar quality – whether for **laundry bar soap production** or delicate **bath soap making**.

Following extrusion, the continuous soap log moves to the cutting stage. Here, **electric washing soap cutter** units provide precise, programmable sizing for bars or slugs. This automation replaces inconsistent manual cutting, ensuring dimensional accuracy and minimal waste. For diverse product ranges, **custom soap cutting machine** configurations handle various shapes and sizes efficiently. The cut bars then proceed through final finishing stages (stamping, cooling, drying) before packaging.

Implementing a turnkey **automatic soap production line** offers manufacturers significant advantages:

* **Enhanced Productivity:** Continuous operation dramatically increases output compared to batch processing.

* **Superior Quality Control:** Automated systems ensure uniformity in weight, density, texture, and appearance across every bar, vital for **beauty soap making lines**.

* **Reduced Labor Costs & Waste:** Automation minimizes manual handling and material loss during cutting and forming.

* **Scalability:** Lines are designed for easy capacity upgrades to meet growing market demands.

* **Versatility:** Configurable lines adeptly switch between **laundry bar soap production line** requirements and **toilet soap finishing line** specifications.

Choosing the right **soap making machine** supplier is paramount. Look for providers offering robust engineering, comprehensive after-sales support, and the ability to tailor the **soap plodder**, **cutter**, and overall **soap making production line** integration to your specific throughput needs and product types. Investing in an optimized **automatic soap production line** is a strategic move towards dominating the competitive soap manufacturing sector.