Modern bar soap manufacturing demands efficiency, consistency, and hygiene. An integrated automatic soap production line replaces labor-intensive manual processes with engineered precision, covering every stage from refining the soap base to finished bars. This sophisticated system is essential for producers targeting high-volume output for laundry soap, bath soap, or specialized beauty soap.

The core process begins with refining the soap base. A high-shear industrial mixer for chemical processing ensures homogeneous blending of fats, oils, alkali, and additives under controlled conditions, critical for product stability. The refined soap mixture is then fed into the heart of the line: the vacuum plodder. This specialized soap plodder machine for bar soap operates under vacuum to remove air pockets, significantly enhancing the soap’s density, smoothness, and lathering properties compared to non-vacuum extrusion. The continuous extrusion produces a uniform, solid log of soap.

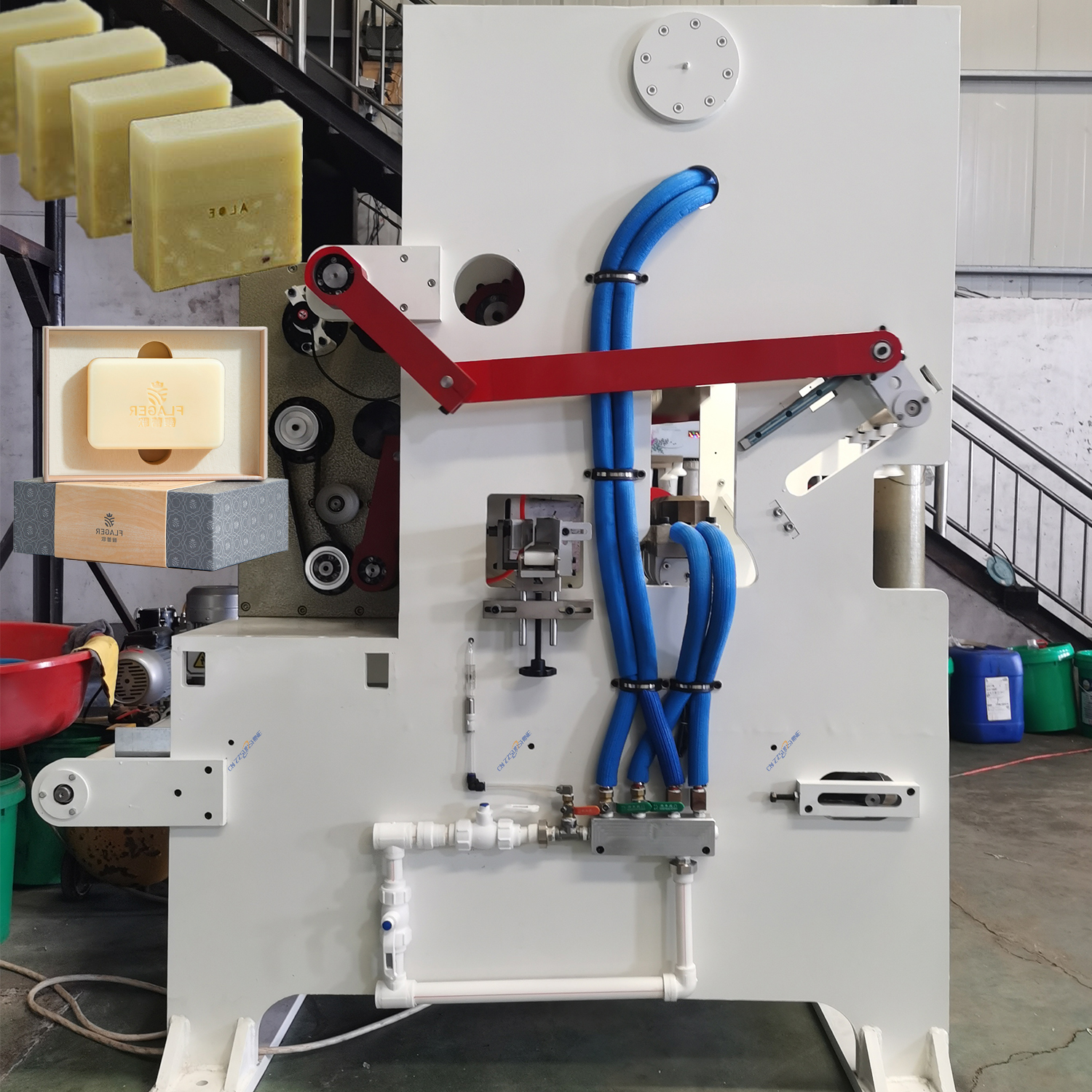

Precise cutting follows extrusion. A custom soap cutting machine, often an electric washing soap cutter, slices the extruded log into precise blanks or bars with minimal waste and consistent dimensions. For high-volume laundry bar soap production lines or toilet soap finishing lines, an automatic soap production line incorporates conveyors to seamlessly transport cut bars through subsequent stages like stamping, cooling, and packaging. Advanced lines might integrate an automatic packing machine for food-grade compliant wrapping, ensuring product integrity.

The advantages are compelling. Automation drastically reduces labor costs and human contact, improving hygiene. Precise control via the vacuum plodder and industrial mixer delivers superior, uniform product quality batch after batch. Increased throughput meets market demands efficiently. For manufacturers seeking reliability, partnering with a reputable OEM specializing in soap making machinery, including robust soap plodders and efficient mixing machines, is paramount. Investing in a well-engineered laundry soap making line or bath soap making machine isn’t just about automation; it’s about securing product excellence and competitive advantage in the demanding bar soap market.