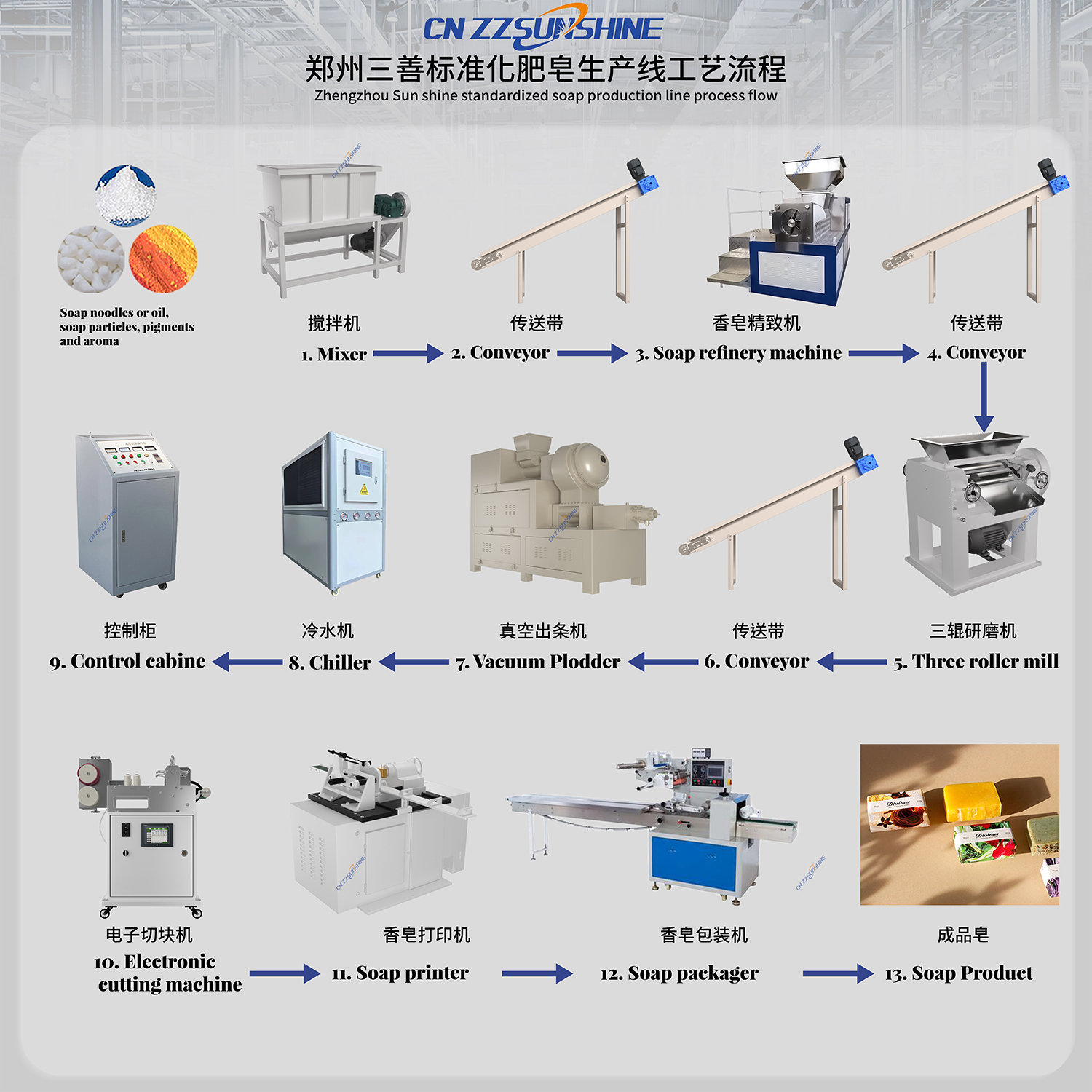

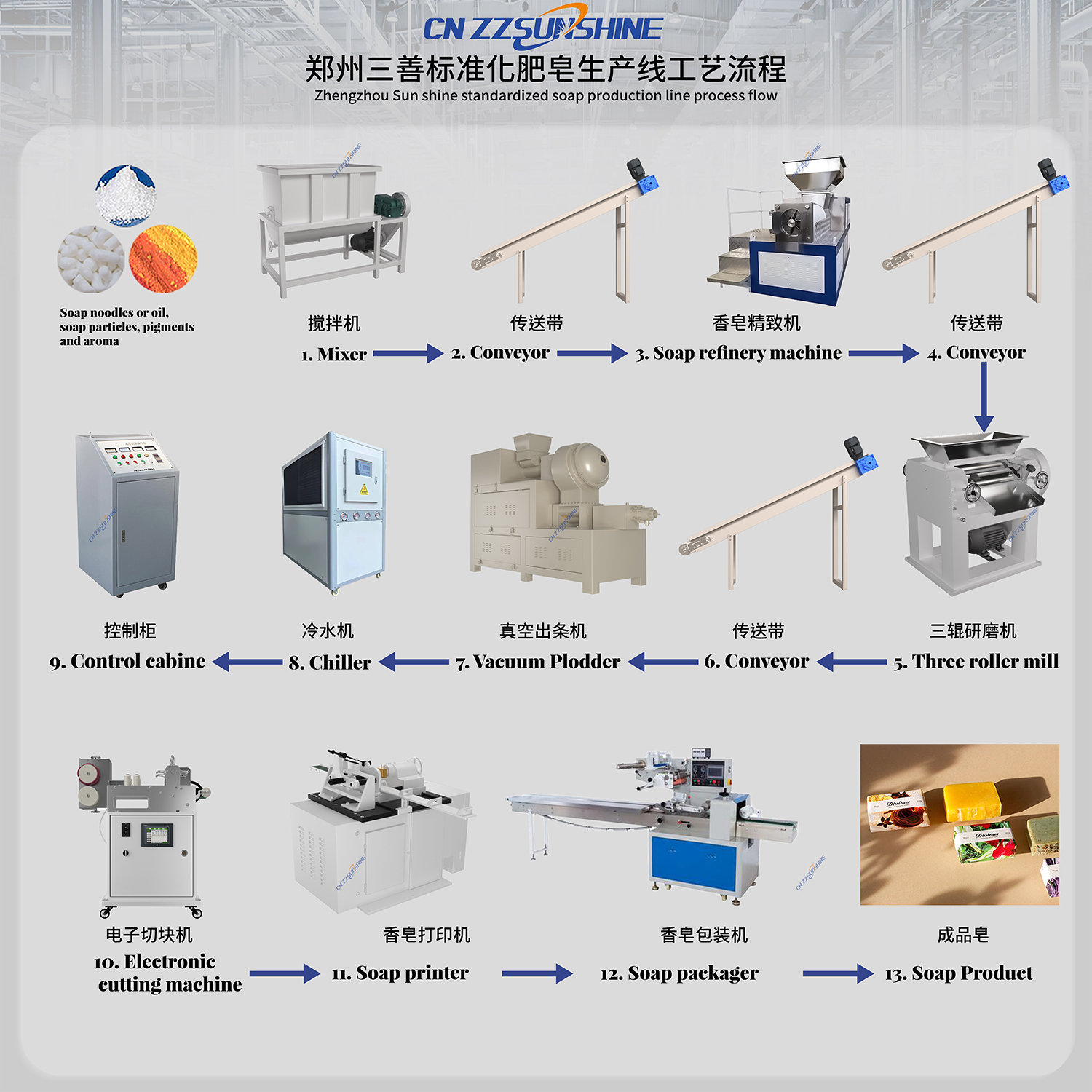

Gone are the days of labor-intensive, inconsistent soap production. Today’s competitive market demands efficiency, hygiene, and unwavering quality control. This is where the **automatic soap production line** becomes indispensable, transforming raw materials into finished bars at remarkable speeds and precision. Integrating specialized machinery like a robust **soap mixer** ensures homogeneous blending of fats, oils, and lye. The mixed paste then moves to a critical component: the **vacuum plodder**. This **soap plodder machine for bar soap** removes air pockets under vacuum, resulting in a denser, smoother paste crucial for high-quality **laundry bar soap production line** or **toilet soap finishing line** outputs. Following extrusion, the continuous soap log requires precise cutting. Modern lines utilize **electric washing soap cutter** units or **custom soap cutting machine** solutions, delivering perfectly sized bars with clean edges, minimizing waste. The entire **soap making production line** operates seamlessly, often requiring minimal manual intervention. For manufacturers targeting specific niches, dedicated configurations exist, such as a **beauty soap making line** incorporating finer milling or specialized additives, or a high-volume **laundry soap making line**. Key advantages are clear: significantly increased output from a single **bath soap making machine** setup, consistent bar weight and density thanks to precision **soap plodder** and **cutter** stages, enhanced product safety through reduced human contact, and lower long-term operational costs. Choosing an integrated **automatic soap production line**, often sourced competitively from a reliable **China feed processing machine supplier** with expertise in diverse processing equipment, represents a strategic investment for any serious soap manufacturer aiming for scalability, superior product quality, and a dominant market position.

Why Automatic Soap Production Lines Are Revolutionizing Manufacturing

Why Automatic Soap Production Lines Are Revolutionizing Manufacturing

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!