Managing high-volume soap manufacturing demands precision and efficiency. Traditional manual methods struggle with consistency and labor costs. An integrated automatic soap production line offers a compelling solution, combining specialized equipment into a cohesive system for laundry bar soap, bath soap, or toilet soap finishing.

The core process begins with the industrial mixer for chemical processing, ensuring homogeneous blending of fats, oils, and caustics. This mixture is then fed into the soap plodder machine for bar soap. Modern lines often utilize a vacuum plodder, crucial for removing air pockets, achieving optimal density, and ensuring extrusion consistency essential for premium quality. The extruded soap log proceeds to cutting. Here, an automatic block cutter machine or a specialized custom soap cutting machine delivers precise, uniform bars. For high-output environments, an electric washing soap cutter minimizes downtime and enhances safety.

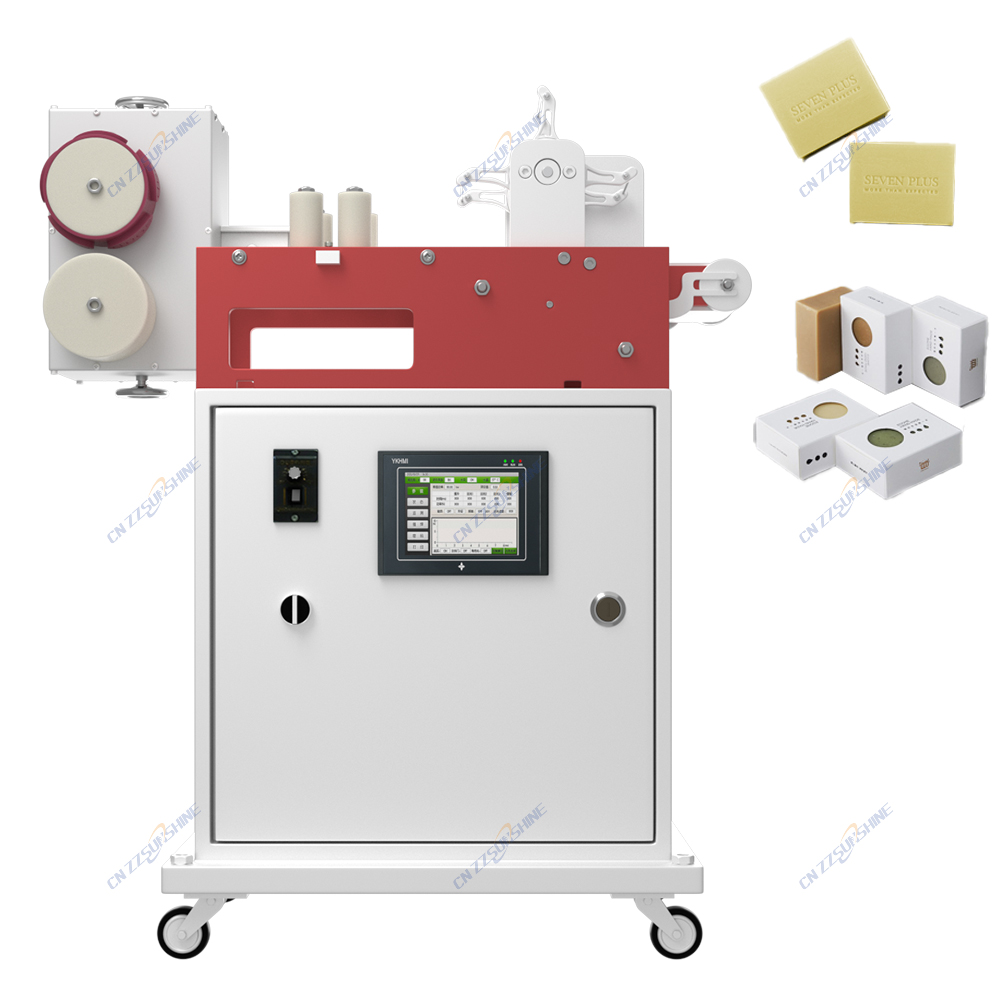

Further down the line, finishing equipment shapes, stamps, cools, and packages the bars. Integrating an industrial chiller for machinery is vital for rapid cooling, maintaining dimensional stability, especially in high-efficiency flour mill plant environments where ambient heat can be an issue. Finally, an automatic packing machine for food-grade standards ensures hygienic, retail-ready presentation.

The advantages are significant. Automation drastically reduces labor dependency, minimizes human contact (improving hygiene), and ensures batch-to-batch uniformity critical for brand reputation. Material waste is lowered through precise control, and overall equipment effectiveness (OEE) increases. Choosing a reliable supplier offering OEM three roller grinding mill expertise for colorants or factory price industrial chiller units supports long-term operational efficiency and return on investment. For manufacturers scaling up, a well-designed automatic soap production line is not just machinery; it’s the foundation for competitive, reliable, and profitable soap manufacturing.