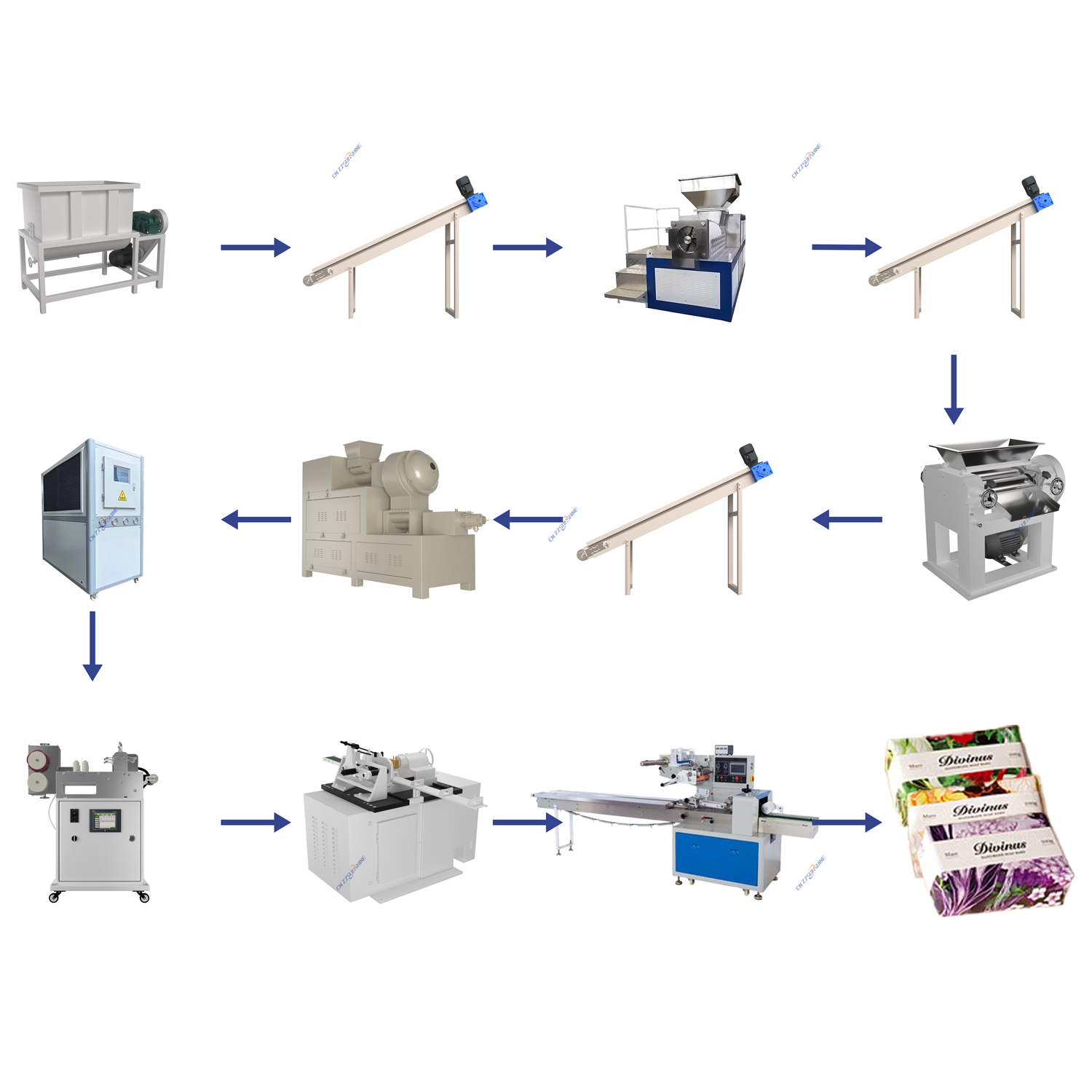

The modern soap manufacturing sector relies heavily on innovative soap making machines to boost efficiency and product quality. These systems integrate seamlessly into an automatic soap production line, handling everything from raw material blending to final cutting. For instance, a high-quality soap mixer ensures uniform mixing of oils, lye, and additives, preventing inconsistencies in batches. This is followed by a vacuum plodder, which removes air pockets and compresses the mixture into solid bars—crucial for creating smooth, durable laundry bar soap production line outputs. Next, a custom soap cutting machine slices the extruded logs with precision, accommodating various sizes for bath soap making machine applications or toilet soap finishing line requirements.

Incorporating an electric washing soap cutter enhances speed and safety, reducing manual errors in high-volume settings. Additionally, supporting equipment like an industrial chiller for machinery maintains optimal temperatures during processing, preventing overheating and extending machine lifespan. Factories benefit from reduced labor costs, faster throughput, and consistent results, whether for laundry soap making line or beauty soap making line setups. Key advantages include up to 40% higher productivity and lower waste, as automated controls minimize human intervention. For cost-effective solutions, manufacturers often seek OEM three roller grinding mills for cosmetics integration or factory-priced units, ensuring scalability. Ultimately, investing in a robust soap plodder and complementary tools like a mixing machine or cutter transforms operations, making it essential for competitive, sustainable soap production in today’s market.