Implementing an efficient soap making production line is crucial for manufacturers aiming for consistent quality and high output. The process hinges on selecting the right machinery integrated into a cohesive laundry bar soap production line or a dedicated toilet soap finishing line.

It starts with the industrial mixer for chemical processing. This equipment must thoroughly homogenize oils, lye, and additives, forming the soap base. Precision mixing directly impacts texture and lathering properties. From the mixer, the soap mass moves to refining stages. A three roller mill for cosmetics, or an OEM three roller grinding mill, is essential here. It refines the soap, removing grit and creating a smooth paste critical for premium bath soap making machine output or beauty soap making line products.

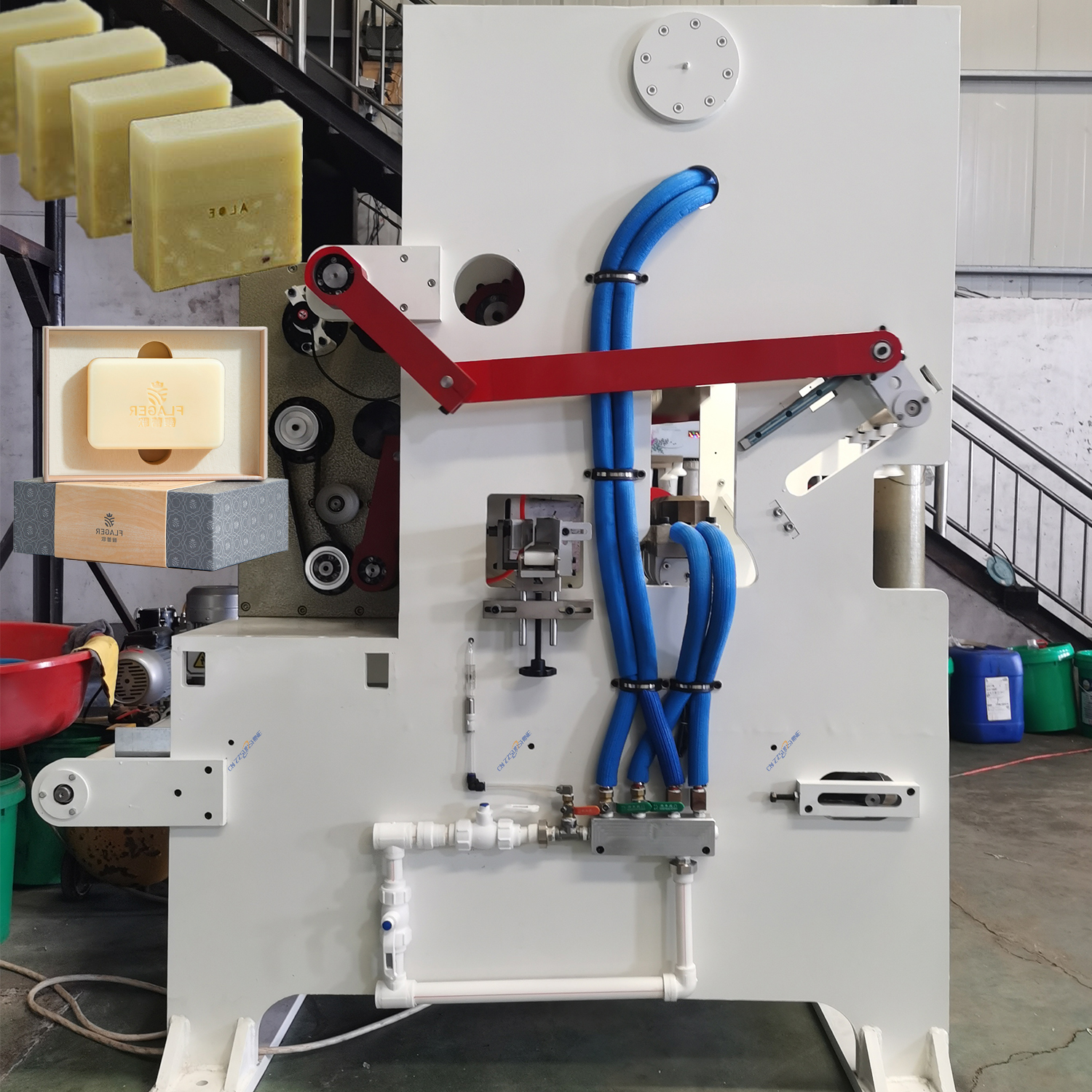

The refined soap then enters the extrusion phase. A vacuum plodder, or soap plodder machine for bar soap, is the heart of the operation. This machine compresses the soap under vacuum, removing air pockets to ensure density and longevity in the final bar. Choosing a high-quality vacuum plodder is non-negotiable for preventing crumbling. Following extrusion, the continuous log requires precise cutting. An automatic soap production line integrates an electric washing soap cutter or a custom soap cutting machine. These cutters deliver uniform bar sizes and weights at high speed, minimizing waste. For large-scale operations like a laundry soap making line, an automatic block cutter machine significantly boosts efficiency.

Optimizing the entire soap making machine sequence – from mixing machine to cutter – demands attention to detail. Partnering with experienced suppliers ensures access to reliable machinery designed for continuous operation. Investing in a well-designed, integrated soap making production line translates to superior bar soap, reduced operational costs, and the ability to scale effectively to meet market demands.