The demand for consistent, high-quality bar soap, whether for laundry or personal care, drives manufacturers towards integrated solutions. Investing in a robust **soap making machine** forms the cornerstone of this strategy. But true efficiency comes from a seamlessly integrated **automatic soap production line**.

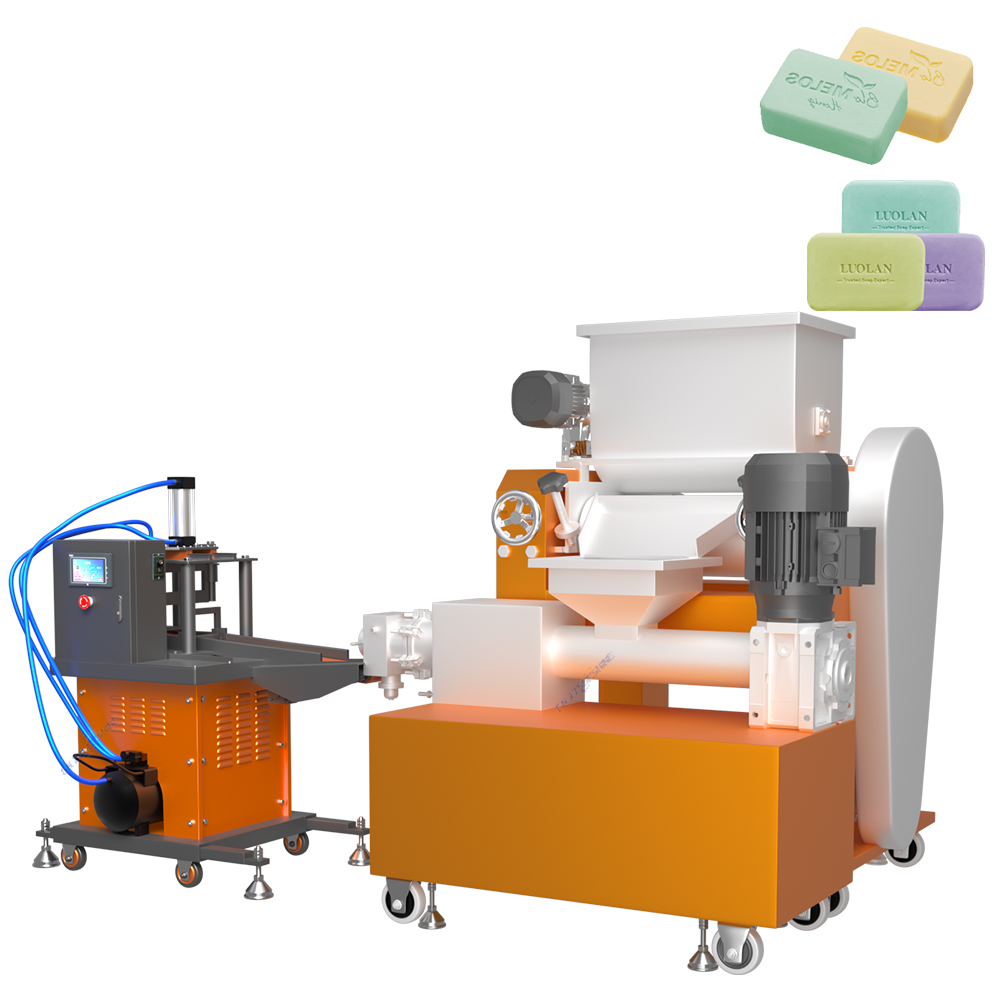

It starts with precision mixing. An industrial **soap mixer**, often a robust **mixing machine** designed for viscous compounds, ensures homogeneous blending of oils, fats, caustics, and additives. This critical stage determines the final bar’s properties. The mixed paste then undergoes refining and extrusion, where a **vacuum plodder** proves indispensable. This key component of the **soap plodder machine for bar soap** removes air pockets under vacuum, producing a dense, uniform noodle essential for a smooth finish and preventing cracking. Whether part of a dedicated **laundry soap making line** or a **toilet soap finishing line**, the vacuum plodder’s role is non-negotiable for premium bars.

Following extrusion, the continuous soap log requires precise sizing. Here, an **automatic block cutter machine** or a specialized **custom soap cutting machine** takes over. Modern lines often feature **electric washing soap cutter** units, ensuring clean, precise cuts without smearing, crucial for both **laundry bar soap production line** output and aesthetic **beauty soap making line** products. Automation at this stage significantly boosts throughput and consistency.

The true power lies in integration. Connecting the **soap mixer**, **soap plodder**, and **cutter** into a single, controlled **automatic soap production line** minimizes handling, reduces labor costs, and maximizes hygiene. It allows for precise control over every parameter, from mixer temperatures to plodder vacuum levels and cutter speeds. This integrated approach, whether building a new **bath soap making machine** setup or upgrading an existing **soap making production line**, delivers tangible ROI through increased output, reduced waste, and superior product quality. For manufacturers seeking scalability and reliability, the modern **soap making machine** ecosystem, centered on automation and integration, is the definitive solution.