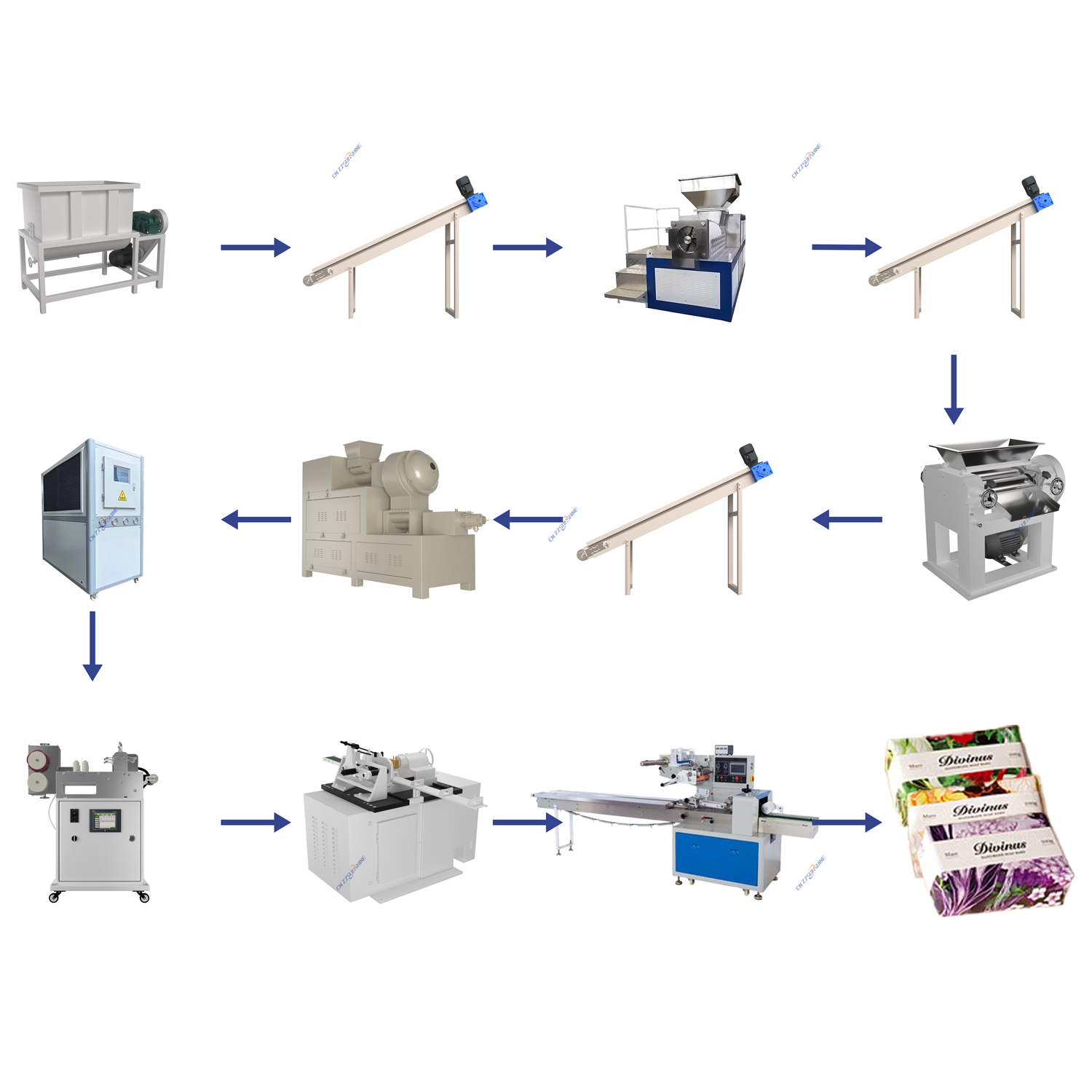

For manufacturers scaling bar soap output, integrating an automatic soap production line is the definitive solution. This integrated system streamlines the entire process, transforming raw materials into consistently high-quality finished bars with minimal manual intervention, significantly boosting throughput and reducing labor costs.

The core of any efficient laundry bar soap production line or toilet soap finishing line begins with robust mixing. A heavy-duty industrial mixer for chemical processing ensures thorough homogenization of fats, oils, lye, and additives, creating a uniform soap base critical for final product integrity. This mixed mass is then fed into the heart of the line: the soap plodder machine. Modern vacuum plodder units are essential, working under reduced pressure to meticulously remove air pockets. This step is non-negotiable for achieving the dense, long-lasting bar structure consumers demand, whether for heavy-duty laundry bars or premium bath soaps. The vacuum plodder compresses and extrudes the soap into a continuous, flawless log.

Precision cutting follows. An automatic soap cutting machine, often an electric washing soap cutter, slices the extruded log into uniform blanks with exceptional accuracy (±0.5mm). This consistency is vital for branding, packaging efficiency, and customer satisfaction. For complex shapes or specialty beauty soap making lines, custom soap cutting machine options can be integrated. Finally, the cut blanks move automatically to stamping, cooling, and packaging stations.

The advantages are clear: unparalleled consistency in bar weight, density, and appearance; drastically reduced manual handling; and optimized production speed. Whether establishing a new laundry soap making line, upgrading a bath soap making machine setup, or implementing a high-volume toilet soap finishing line, a well-engineered automatic production line delivers measurable ROI. Key components like the vacuum plodder and industrial mixer define the line’s capability. Partnering with experienced manufacturers offering OEM solutions ensures the line meets specific throughput targets (from 200kg/hr to 2MT/day) and bar specifications, guaranteeing optimal performance and reliability for years of continuous operation.