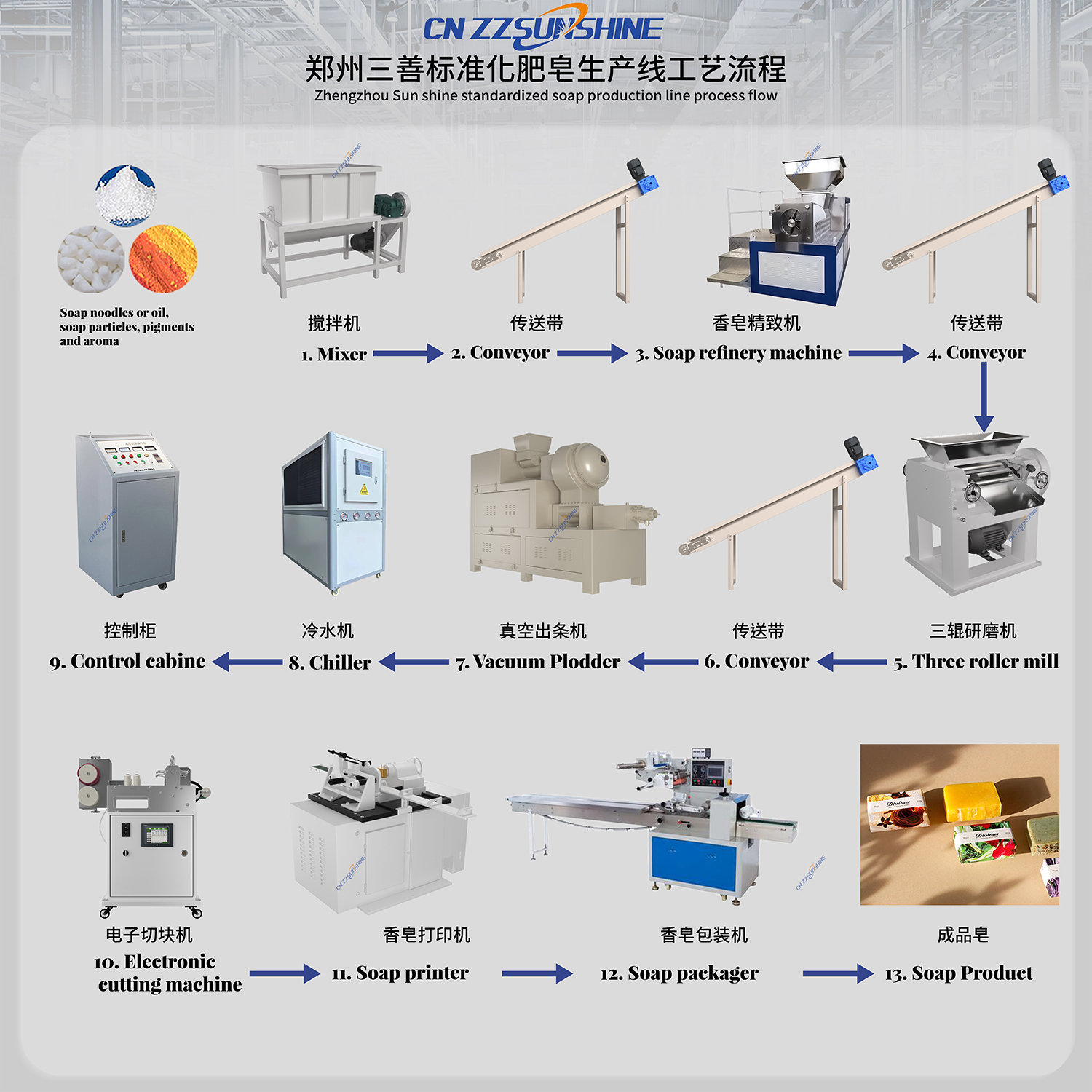

Running a competitive soap manufacturing operation demands a reliable, high-output soap making production line. The core of any efficient line lies in its processing stages: thorough mixing, precise extrusion, and consistent cutting. An industrial mixer for chemical processing is fundamental, ensuring homogeneous blending of oils, fats, lye, and additives – critical for final bar quality and stability. This initial mixing stage sets the foundation for the entire process.

Following mixing, the soap mass undergoes extrusion. This is where a robust soap plodder machine, particularly a vacuum plodder, becomes indispensable. The vacuum plodder removes air pockets, creating a denser, smoother bar soap that lathers better and lasts longer. Consistent extrusion pressure is vital for uniform density throughout the bar, whether destined for laundry bar soap production lines or premium bath soap making machines. A high-quality plodder significantly reduces issues like cracking or crumbling.

The extruded continuous soap log then moves to cutting. Precision is paramount here. While manual cutters exist, an automatic soap production line integrates an electric washing soap cutter or a custom soap cutting machine. These automated cutters deliver uniform bar weights and dimensions at high speeds, essential for both packaging efficiency and brand consistency. This is especially crucial for high-volume laundry soap making lines and intricate toilet soap finishing lines requiring precise dimensions for wrapping and stamping. Integrating an automatic block cutter machine further streamlines the process for larger-scale operations.

Finally, the cut bars proceed to finishing – cooling, stamping, and packaging. Integrating an industrial chiller for machinery ensures proper cooling rates, preventing deformation. A high-efficiency flour mill plant might seem unrelated, but the principle applies: optimizing each stage, from the mixer and plodder to the cutter and finishing equipment, is key. Partnering with a reputable OEM three roller grinding mill manufacturer or a China feed processing machine supplier often brings engineering expertise transferable to soap machinery, ensuring robust construction and process understanding. Investing in a well-designed, automated soap production line, potentially incorporating a soap plodder and soap mixer from specialized suppliers, directly impacts throughput, consistency, and ultimately, profitability. Choosing equipment with factory price industrial chiller options and reliable mixing machines offers long-term value for your soap making machine investment.