In today’s competitive manufacturing landscape, a high-performance soap making production line is essential for businesses aiming to scale operations while maintaining quality and cost-efficiency. This integrated system streamlines the entire process from raw material mixing to final bar soap packaging, leveraging automation to reduce labor costs and minimize human error. At the heart of the line, the soap mixer ensures uniform blending of ingredients like oils and fragrances, critical for consistent product texture. Following this, the vacuum plodder compacts the mixture under controlled pressure, eliminating air bubbles to create dense, durable bars—ideal for both laundry soap making line applications and premium toilet soap finishing line outputs.

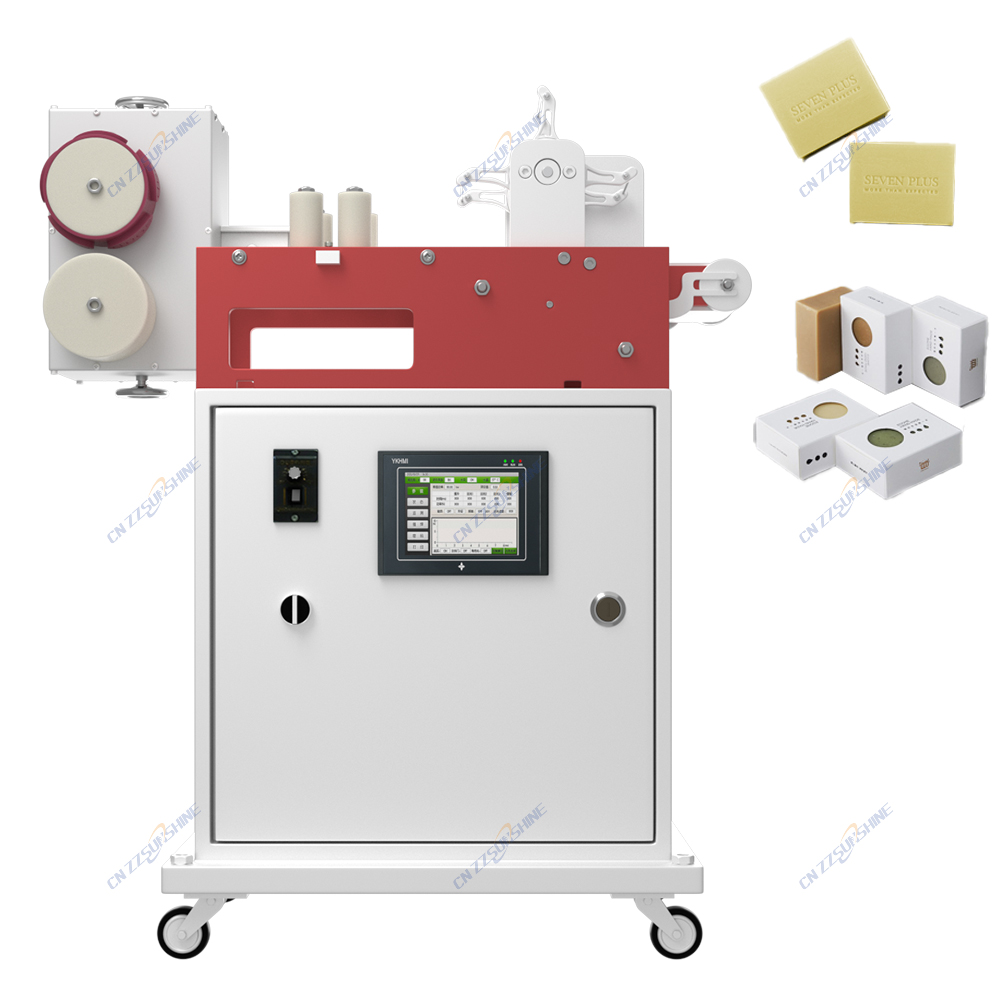

Key components such as the soap plodder machine for bar soap and an electric washing soap cutter enhance precision, allowing for customizable sizes and shapes tailored to specific markets, including beauty soap making line requirements. The automatic soap production line incorporates advanced sensors and programmable logic controllers (PLCs) to monitor variables like temperature and humidity, ensuring optimal conditions throughout. This not only boosts throughput by up to 40% but also supports eco-friendly practices by reducing waste. For instance, a laundry bar soap production line can integrate with recycling systems to reuse trimmings, cutting material costs by over 15%.

Moreover, modern setups like the bath soap making machine offer flexibility for OEM customization, enabling manufacturers to adapt quickly to changing consumer demands. With features such as energy-efficient motors and easy-to-clean surfaces, these lines lower operational expenses while meeting stringent hygiene standards. Investing in a vacuum plodder and automatic cutter setup translates to faster ROI, as seen in factories reporting payback within 18 months. Ultimately, a well-designed soap making production line empowers producers to achieve higher margins and superior product consistency, making it a smart choice for global expansion. Partner with experienced suppliers to explore tailored solutions that align with your production goals.