In today’s competitive soap manufacturing market, efficiency, consistency, and hygiene are paramount. Implementing a fully integrated automatic soap production line is no longer a luxury but a strategic necessity for businesses aiming to scale profitably, whether producing laundry bar soap, bath soap, or premium toilet soap.

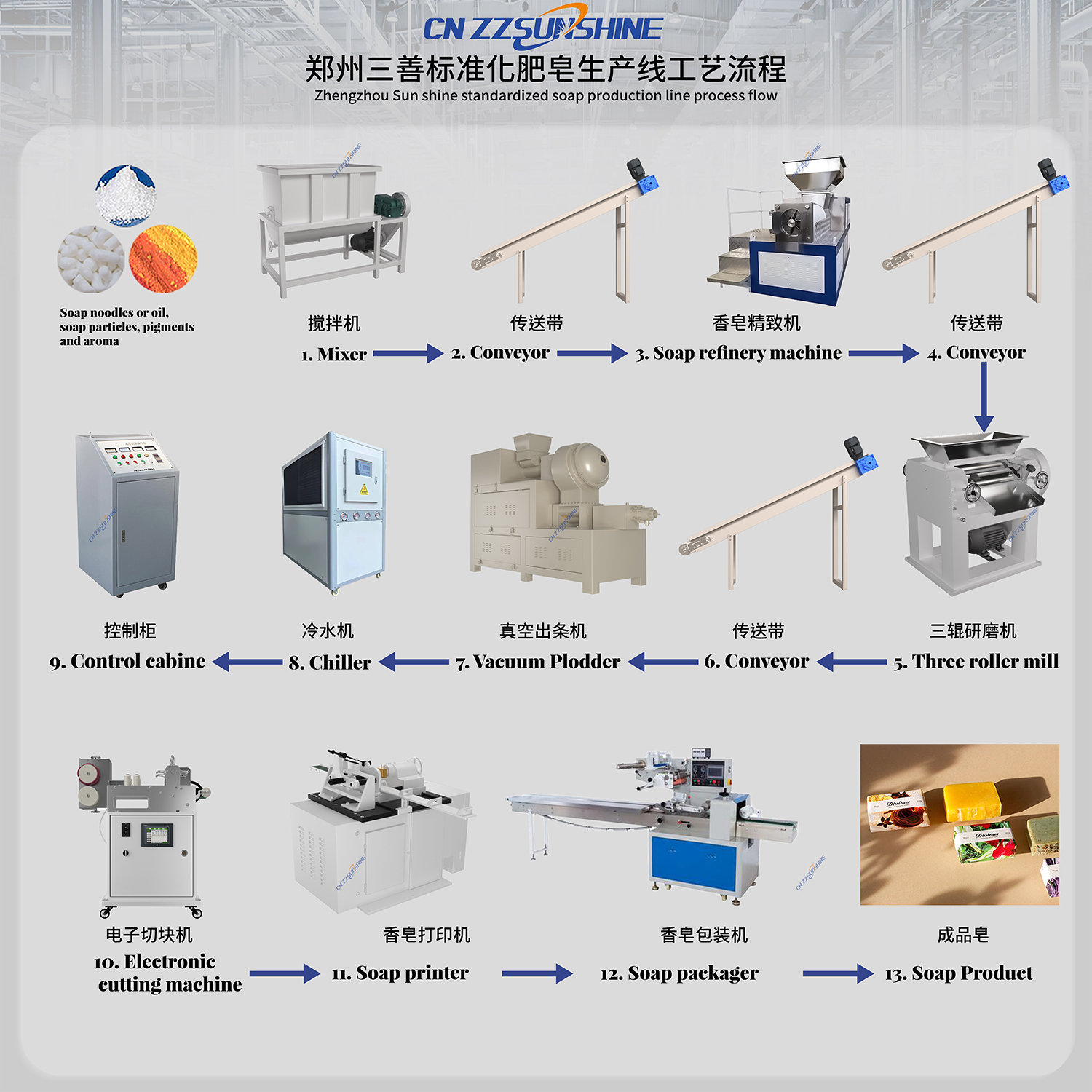

A modern automatic soap production line seamlessly integrates several critical stages. It begins with precise ingredient handling using a robust industrial soap mixer, ensuring homogeneous blending of fats, oils, alkalis, and additives crucial for quality. The mixed soap base then undergoes refining and de-aeration in a critical component: the vacuum plodder. This specialized soap plodder machine removes air pockets under vacuum, resulting in a denser, smoother bar with superior lather and longer lifespan – essential for both laundry bar soap production lines and bath soap making machines.

Following extrusion from the vacuum plodder, the continuous soap log enters the forming stage. Here, consistency is key. Sophisticated plodders ensure uniform density before the log is precisely sized. Cutting is handled with high accuracy by an electric washing soap cutter or a custom soap cutting machine, designed to minimize waste and produce bars of exact dimensions, critical for packaging and consumer appeal. For premium toilet soap finishing lines, additional milling or stamping units might be integrated downstream.

The advantages are compelling. Automation drastically reduces labor costs and minimizes human contact, enhancing hygiene – a vital factor in toilet soap finishing lines. Output consistency improves dramatically, ensuring every bar meets specifications. Throughput scales efficiently, allowing manufacturers to meet large orders reliably. Furthermore, integrated systems offer flexibility; lines can often be configured for both laundry bar soap production and beauty soap making lines with appropriate adjustments and tooling.

Choosing the right partner is critical. Look for suppliers offering comprehensive solutions, including OEM three roller grinding mills for specialized refining if needed, and robust support. The ideal automatic soap production line balances high efficiency with reliability and offers customization options to meet specific product requirements and factory layouts, ultimately delivering a rapid return on investment through optimized soap making machine processes.