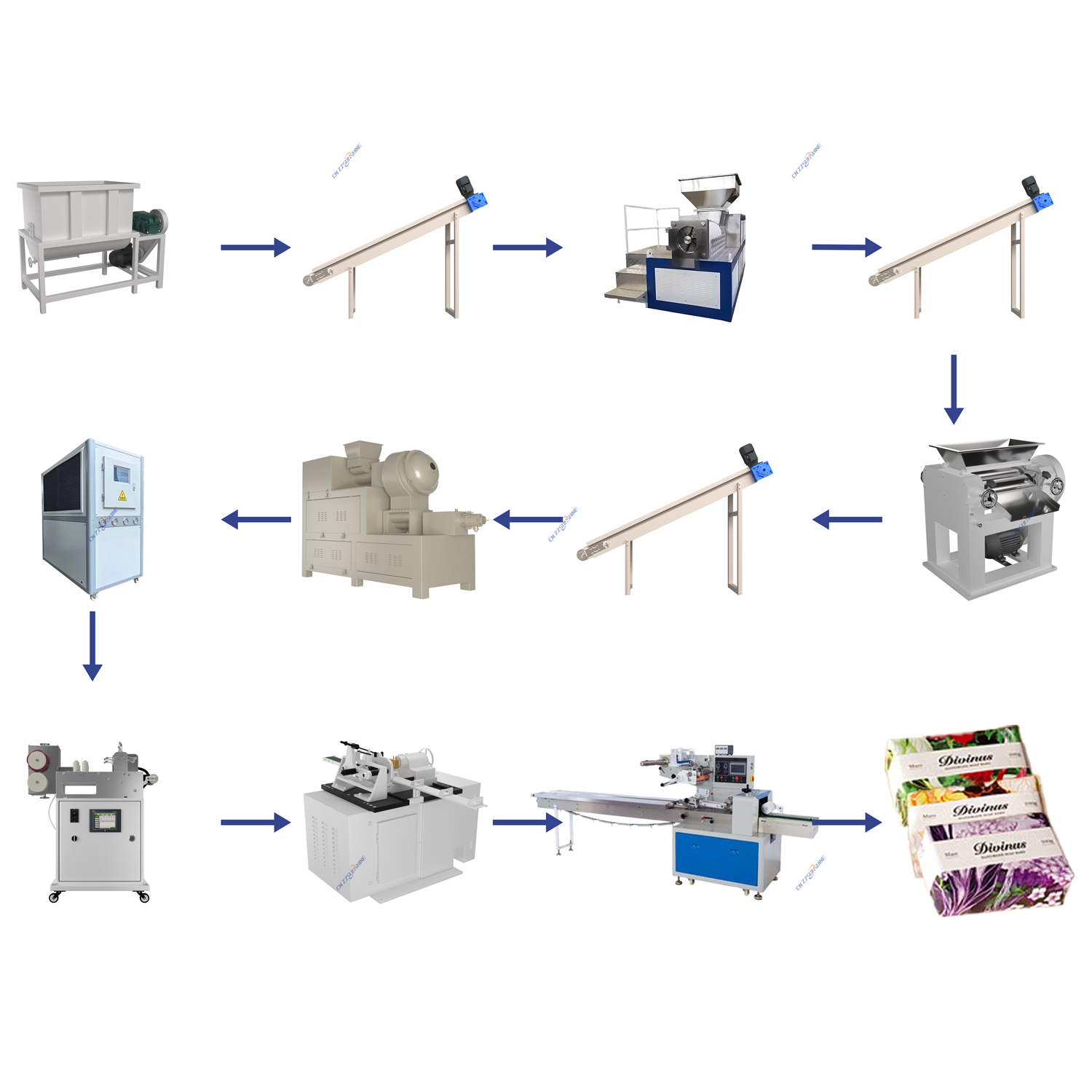

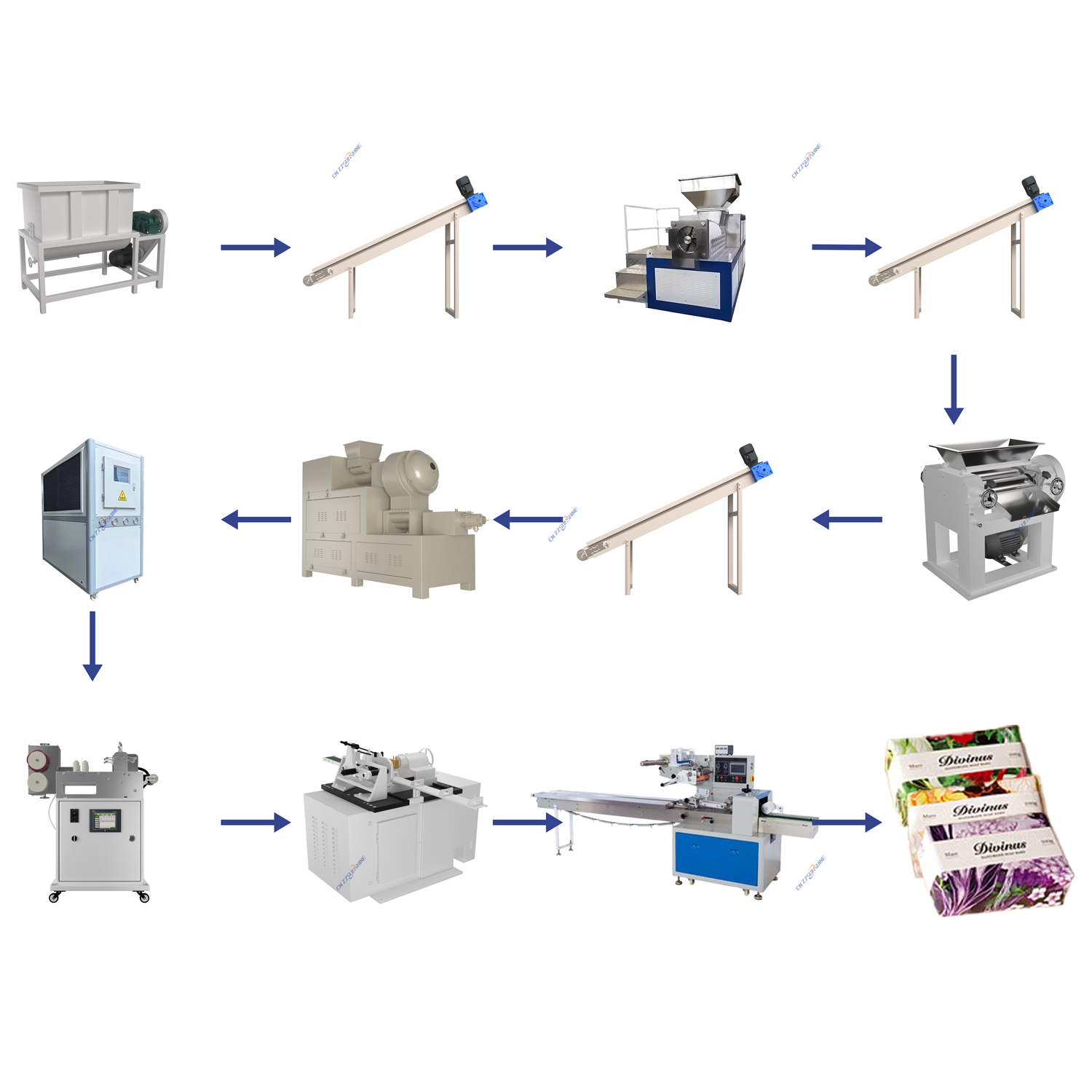

In today’s fast-paced manufacturing landscape, a soap making production line is indispensable for factories aiming to boost output while maintaining top-tier quality. This integrated system typically includes components like a soap mixer for blending raw materials uniformly, ensuring consistent texture in every batch. The vacuum plodder plays a critical role by removing air pockets, which prevents cracking and enhances durability in products such as laundry bar soap production lines. For precise sizing, an electric washing soap cutter automates slicing, reducing waste and improving safety compared to manual methods. In toilet soap finishing lines, additional stages like stamping and wrapping are seamlessly incorporated to add brand details. Similarly, a beauty soap making line might integrate a three roller mill for cosmetics to refine particles for smoother, luxury bars. Automation across these elements, from the soap plodder machine to the cutter, minimizes human error and cuts labor costs by up to 40%, making it ideal for high-volume operations. Customization options, such as OEM three roller grinding mills, allow manufacturers to tailor systems for specific needs, like bath soap making machines with unique fragrances. By adopting an automatic soap production line, companies not only accelerate throughput but also ensure compliance with hygiene standards, driving long-term savings and market competitiveness. Ultimately, investing in a robust soap making machine transforms production, delivering reliability and scalability for global supply chains.

Enhancing Efficiency with a Modern Soap Making Production Line

Enhancing Efficiency with a Modern Soap Making Production Line

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!