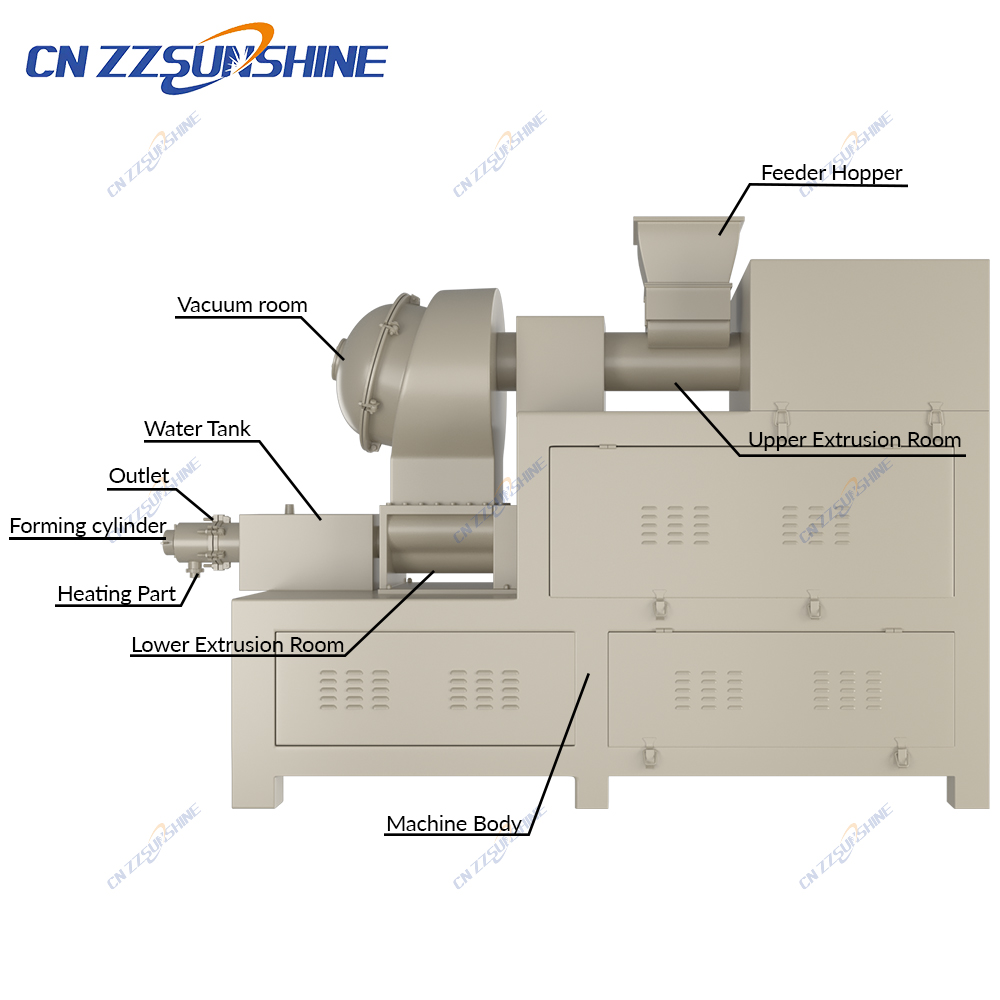

Transitioning from manual methods or outdated equipment to a fully integrated automatic soap production line is the definitive step for manufacturers aiming to scale output, ensure consistency, and meet stringent quality standards. Central to this automation is the vacuum plodder, a critical component determining the final bar’s density, texture, and performance. Unlike simple soap mixers, the vacuum plodder subjects the blended soap base to intense pressure and vacuum within its barrel, meticulously expelling trapped air. This crucial step prevents air pockets in the finished bars, ensuring uniform density, smooth texture, and significantly reducing breakage during use – a common complaint with non-vacuum processed soap.

A modern vacuum plodder feeds the homogenized soap noodles continuously, extruding a solid, dense log. This log is then seamlessly transferred downstream within the laundry bar soap production line or toilet soap finishing line. Depending on the setup, high-precision automatic block cutter machines or specialized log saws slice the extruded log into precise billets. These billets are subsequently stamped, shaped, and potentially polished on the bath soap making machine or beauty soap making line. The integration of an electric washing soap cutter ensures clean, consistent sizing crucial for packaging efficiency.

The efficiency gains are substantial. A well-designed automatic soap production line incorporating a robust vacuum plodder operates continuously, minimizing downtime between batches common with older soap plodder machines. This translates directly to higher throughput and lower per-unit costs. Furthermore, the process allows for greater flexibility. Manufacturers can easily adapt the line, potentially incorporating a custom soap cutting machine, to switch between different soap formulations (laundry vs. toilet soap) or bar sizes without major retooling delays. For businesses seeking reliable, high-capacity solutions, partnering with experienced OEM equipment providers specializing in soap making machinery ensures access to technology designed for optimal vacuum efficiency, minimal waste, and maximum uptime, solidifying your competitive edge in the market.