For businesses aiming to scale bar soap production efficiently, a dedicated soap making production line is non-negotiable. Whether targeting the laundry soap market or premium toilet soap segments, integrating the right machinery ensures consistent quality, operational efficiency, and cost-effectiveness. Understanding the core components of an automatic soap production line is crucial.

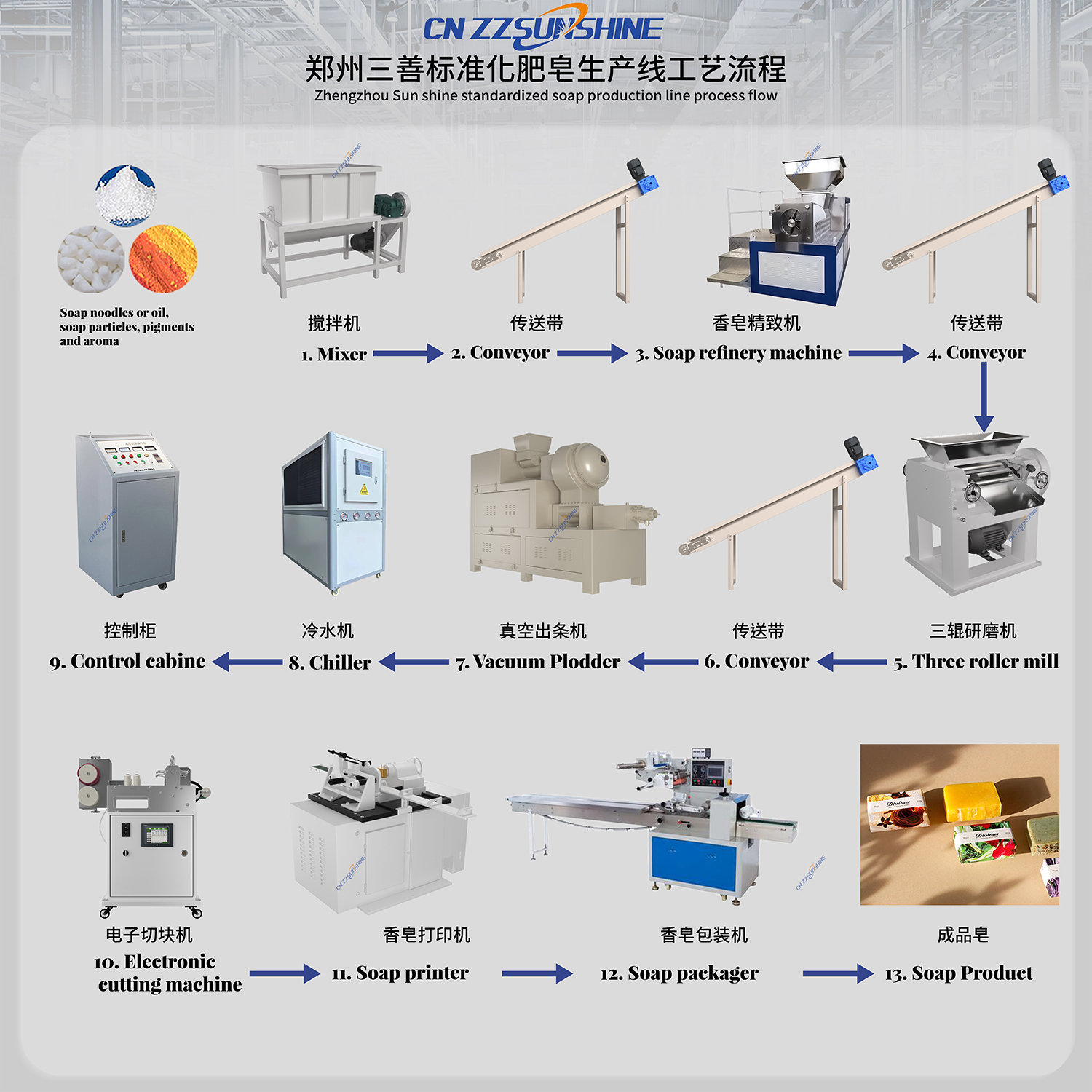

The process typically begins with precise formulation. An industrial mixer for chemical processing blends fats, oils, lye, additives, and fragrances into a homogenous soap base. This critical stage demands robust mixing machines capable of handling viscous materials and ensuring thorough amalgamation. From this mixer, the soap base moves to refining.

A vacuum plodder is the heart of modern soap finishing lines. This specialized soap plodder machine compresses the mixed soap base under vacuum, eliminating air pockets and ensuring a dense, uniform texture essential for high-quality bar soaps like bath soap or laundry bars. Modern vacuum plodders offer superior de-aeration compared to older open plodder designs. The extruded soap log then proceeds to shaping.

Here, an automatic soap cutter machine is indispensable. Options range from high-speed guillotine-style automatic block cutter machines to sophisticated electric washing soap cutters designed for precise sizing with minimal waste. For specialized shapes or embossing, custom soap cutting machines can be integrated into the toilet soap finishing line or laundry bar soap production line. Finally, bars move to stamping, cooling tunnels, and automated packing.

Leading manufacturers offer complete solutions, from laundry soap making lines to intricate beauty soap making lines. Opting for an integrated system from a single supplier often yields benefits like OEM compatibility, optimized factory price industrial chiller integration for cooling, and comprehensive after-sales support. Investing in a high-efficiency, automated soap production line, featuring a reliable soap plodder, industrial mixer, and precise cutter, translates directly to increased output, reduced labor costs, and superior product consistency for competitive markets.