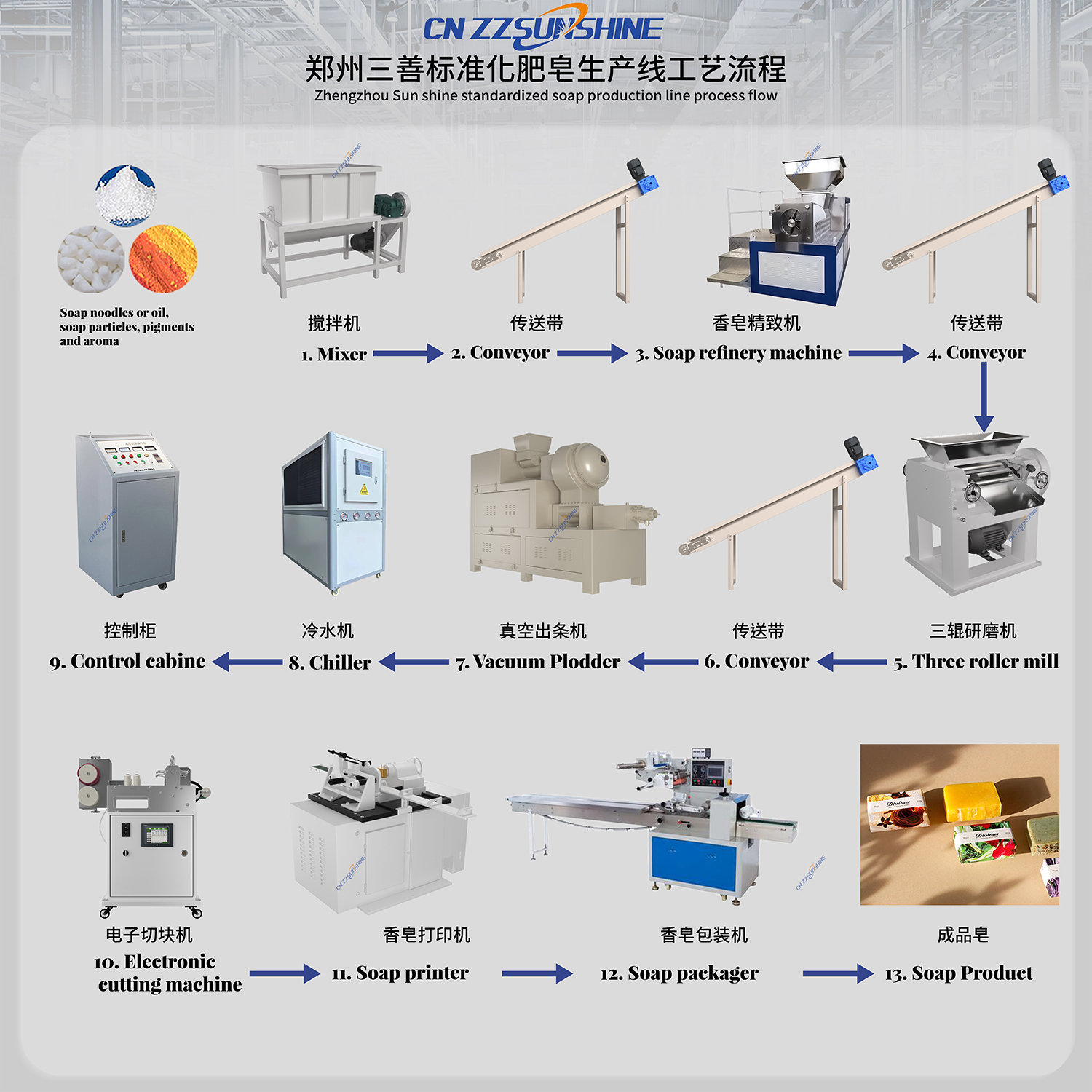

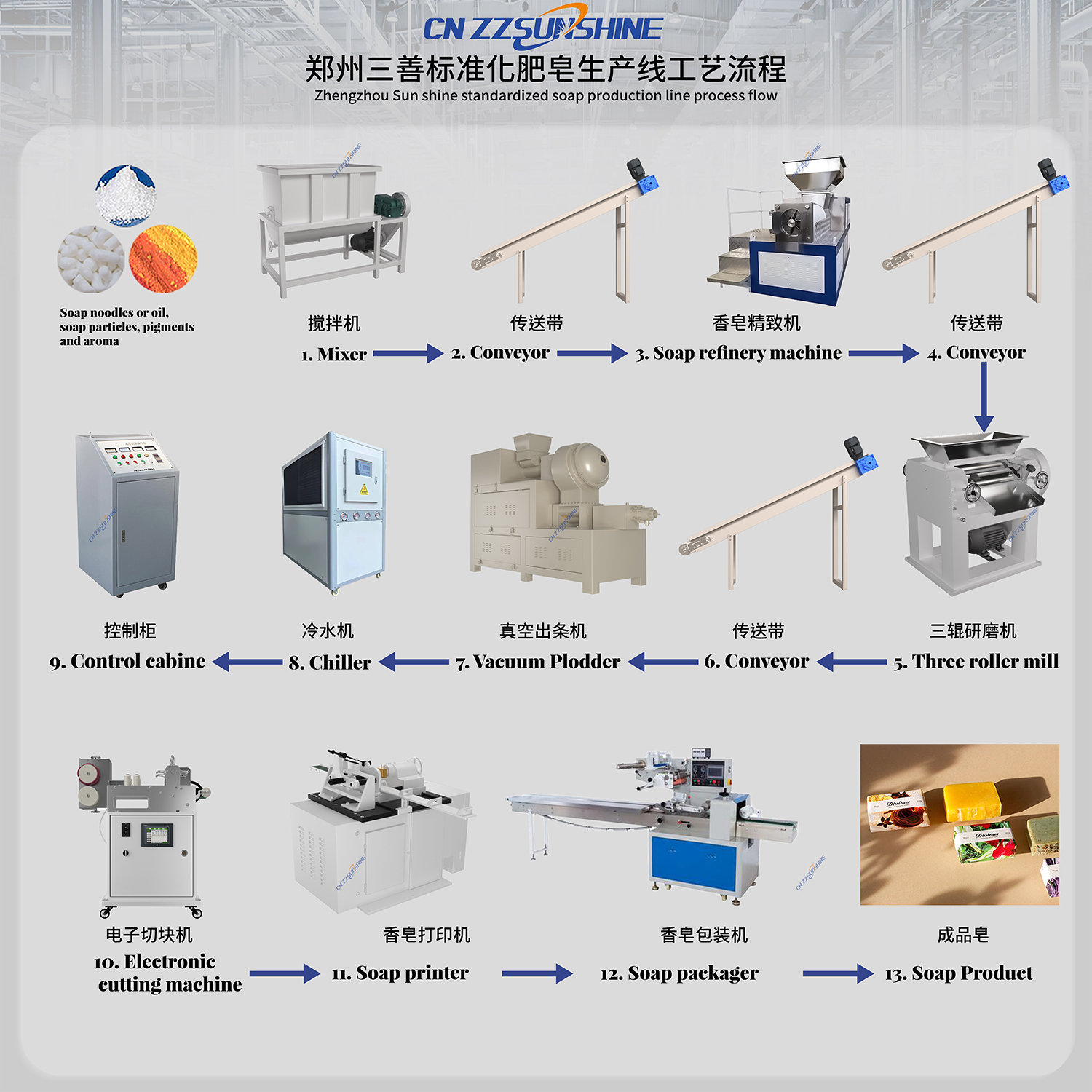

Manufacturers globally are adopting automatic soap production lines to revolutionize hygiene manufacturing, addressing demands for consistent quality and cost-effectiveness. This integrated system combines advanced components like a vacuum plodder for uniform texture, a soap mixer for precise blending of ingredients, and an electric washing soap cutter for clean, accurate cuts. For instance, laundry bar soap production lines utilize these elements to handle high volumes, reducing labor costs by up to 50% compared to manual methods. The beauty soap making line variant incorporates custom soap cutting machines to create intricate shapes for premium products, while bath soap making machines ensure gentle processing for sensitive formulations. Key advantages include minimized waste through automated controls and scalability for diverse markets, such as toilet soap finishing lines that package goods seamlessly. With innovations like industrial mixers for chemical processing integrated into the workflow, these systems boost throughput by 30-40%, making them ideal for large-scale operations. Investing in an automatic soap production line not only elevates hygiene standards but also future-proofs businesses against rising competition, delivering rapid ROI through energy-efficient designs and reliable performance.

Automatic Soap Production Line: Enhancing Efficiency in Modern Soap Manufacturing

Automatic Soap Production Line: Enhancing Efficiency in Modern Soap Manufacturing

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!