The demand for high-volume, consistent laundry bar soap production drives the need for integrated, efficient soap making lines. At the heart of a modern laundry soap making line lies seamless integration of specialized equipment, each stage critical to achieving uniform quality and operational cost-effectiveness. It starts with robust mixing. An industrial mixer for chemical processing must handle the rigorous blending of fats, oils, caustics, and additives under controlled conditions, forming the initial soap base crucial for downstream quality.

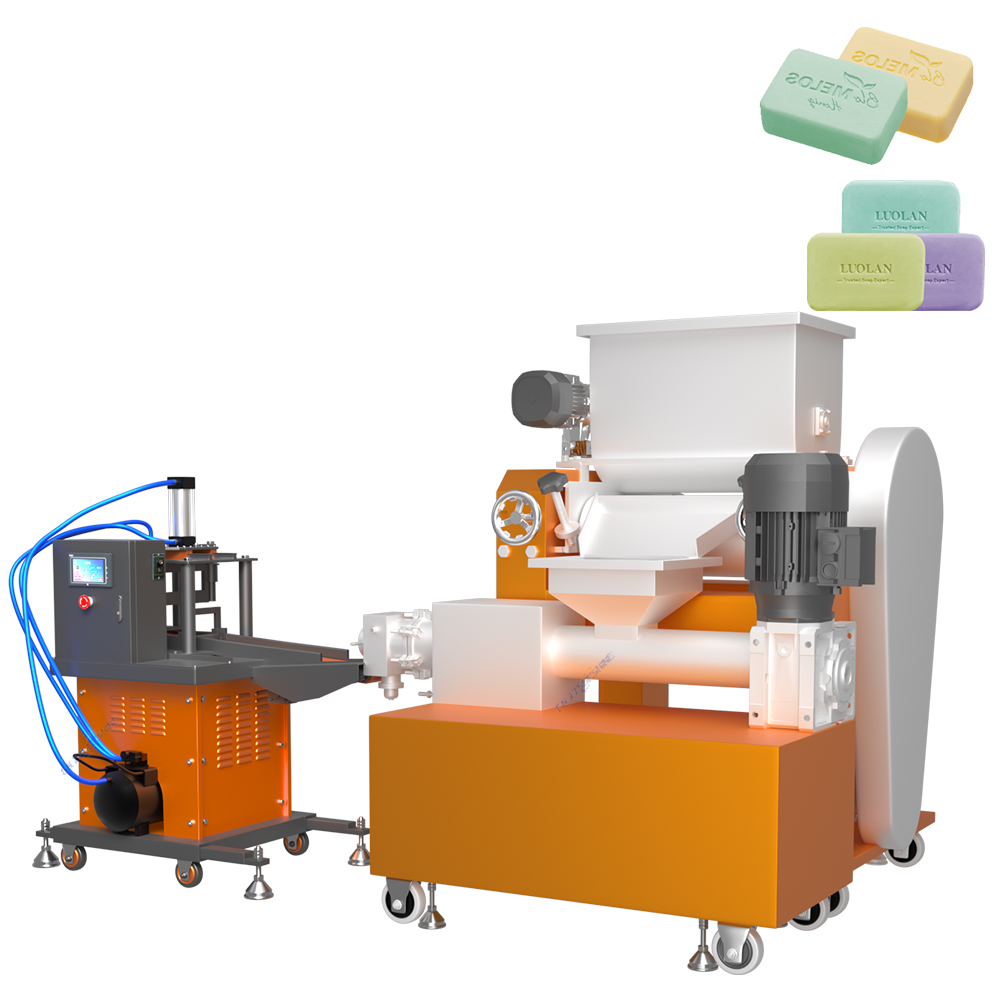

This mixed base then undergoes refining and homogenization, often utilizing a vacuum plodder. This key component in the soap plodder machine stage removes air pockets under vacuum, significantly enhancing the soap’s density, texture, and lathering properties – essential for both laundry bar soap production line output and end-user satisfaction. The vacuum plodder ensures the soap mass is perfectly conditioned for extrusion.

Following plodding, the continuous soap log enters the shaping and cutting phase. Here, an automatic soap production line leverages precision cutting equipment. An electric washing soap cutter, or custom soap cutting machine, provides clean, consistent cuts at high speeds, dramatically reducing labor costs and waste while ensuring uniform bar dimensions. This automation is vital for maintaining throughput in large-scale laundry soap making lines.

Finally, the cut bars proceed to the toilet soap finishing line or laundry soap finishing section. This stage typically involves stamping, branding, cooling, and packaging. Integrating an automatic packing machine for food-grade materials (suitable for soap) completes the process, ensuring hygienic and efficient wrapping for distribution. Choosing the right components, like a reliable vacuum plodder and efficient cutter, directly impacts line productivity and product quality.

For manufacturers seeking competitive advantage, sourcing a complete laundry bar soap production line, including high-performance plodder machines and precise cutters, often leads to the best return on investment. Partnering with experienced suppliers offering OEM solutions ensures the line meets specific capacity, formulation, and bar size requirements, optimizing the entire soap making process from raw materials to finished packs.