Implementing a cohesive soap making production line is paramount for manufacturers aiming to scale output while maintaining consistent quality and competitive margins. Moving beyond standalone units like a basic soap mixer or a simple soap plodder, integrated lines automate the entire process from raw material handling to finished bar packaging. This integration drastically reduces labor costs and minimizes contamination risks.

A robust line typically starts with high-capacity mixing machines. Industrial mixers for chemical processing ensure homogeneous blending of fats, oils, lye, and additives under controlled conditions. The mixed soap base then undergoes refining, often utilizing a three roller mill for cosmetics-grade smoothness, essential for premium toilet soap finishing lines or beauty soap making lines. This step is critical for achieving the desired texture and eliminating air pockets.

The refined soap mass proceeds to the core extrusion stage via a vacuum plodder. This specialized soap plodder machine for bar soap compresses the soap under vacuum, removing residual air and creating a dense, uniform log. The vacuum environment is crucial for preventing bubbles that weaken the final bar structure. Consistent extrusion quality directly impacts the efficiency of downstream cutting.

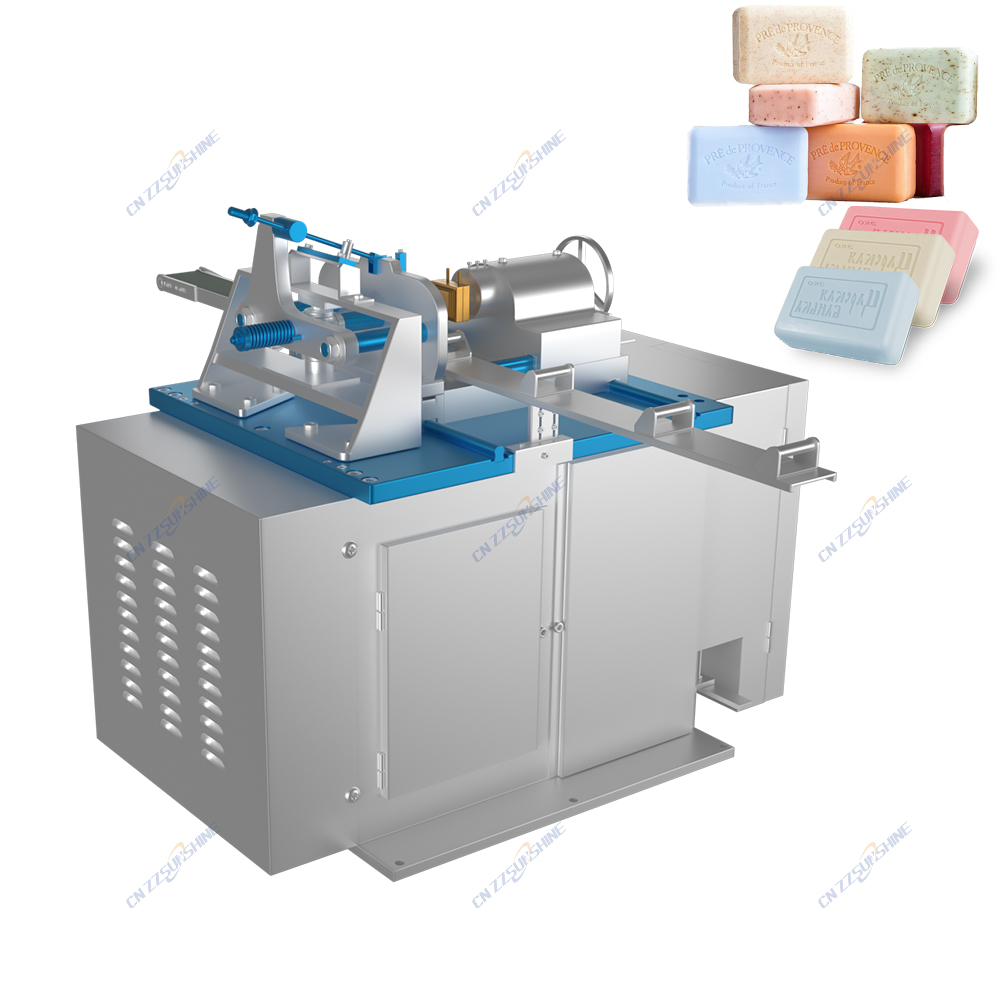

Following extrusion, the continuous soap log is precisely cut into individual bars. Modern lines employ highly accurate custom soap cutting machines. Options range from electric washing soap cutter units for hard laundry bars to more delicate cutters for bath soap making machine applications. An automatic block cutter machine ensures uniform weight and dimensions with minimal waste, vital for both laundry bar soap production lines and toilet soap finishing.

Integration with auxiliary equipment is key. An industrial chiller for machinery is often indispensable to maintain optimal temperatures during mixing and plodding, especially in warmer climates. Furthermore, an automatic packing machine for food-grade standards seamlessly handles the wrapped or unwrapped bars, completing the automated workflow. Partnering with a reliable supplier offering factory price industrial chiller units and OEM three roller grinding mill components ensures long-term operational efficiency and access to technical support.

Ultimately, investing in a well-designed automatic soap production line, incorporating the right balance of a robust soap plodder, efficient mixing machine, and precise cutter technology, delivers significant returns through higher throughput, superior product consistency, reduced waste, and lower operational costs. This holistic approach is fundamental for success in today’s competitive soap manufacturing sector.