Modern soap manufacturing demands precision, hygiene, and high throughput. An integrated automatic soap production line is no longer a luxury but a necessity for competitive factories. This sophisticated chain of interconnected machinery replaces manual, batch-oriented processes with a continuous, streamlined operation, significantly boosting output consistency and reducing labor costs.

The heart of the line often begins with a robust industrial mixer for chemical processing, ensuring homogeneous blending of oils, fats, lye, and additives. This critical stage determines the base quality of the final bar. The mixed soap base then moves to refining. Here, a three roller mill for cosmetics or specialized soap applications meticulously grinds the soap, refining its texture and removing air pockets for a smoother, denser bar. The refined soap noodles are then fed into the core extrusion equipment: a high-capacity soap plodder machine for bar soap. Modern vacuum plodder technology is particularly crucial, removing residual air under vacuum pressure to create a hard, long-lasting bar with minimal bubbles or cracking.

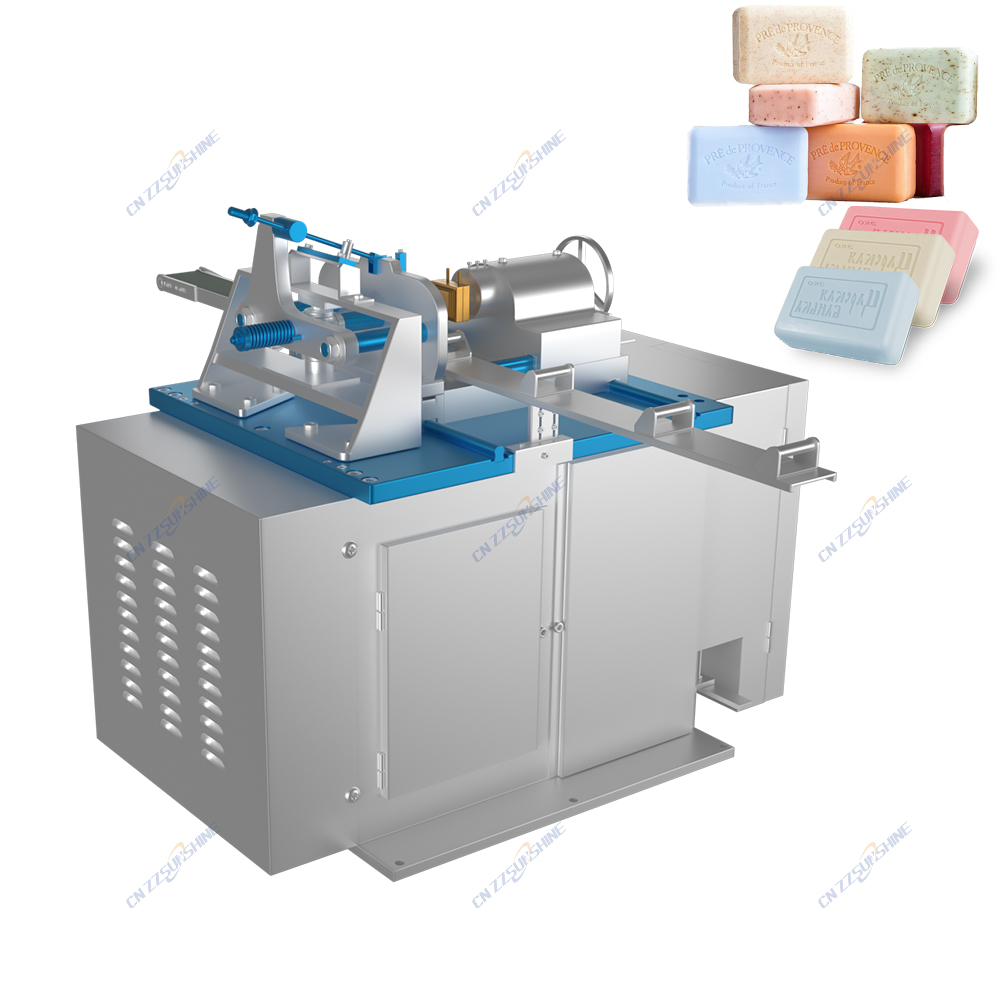

Following extrusion, the continuous soap log requires precise cutting. An electric washing soap cutter or a custom soap cutting machine delivers accurate, programmable sizing with clean edges, essential for both laundry bar soap production lines and delicate toilet soap finishing lines. Depending on the product type (laundry soap, bath soap, beauty soap), the line may incorporate additional stages like stamping, cooling tunnels, or polishing units within the toilet soap finishing line segment.

Investing in a complete automatic soap production line, encompassing the soap mixer, vacuum plodder, and precision cutter, offers substantial returns. Factories achieve consistent quality control, enhanced worker safety by minimizing direct contact with raw materials, and the ability to scale production rapidly. For manufacturers seeking to optimize their laundry soap making line or elevate their bath soap making machine capabilities, integrating a fully automated system is the definitive path toward superior efficiency and market competitiveness. Partnering with experienced suppliers who understand the nuances of soap plodder technology and integrated line design is paramount for successful implementation.