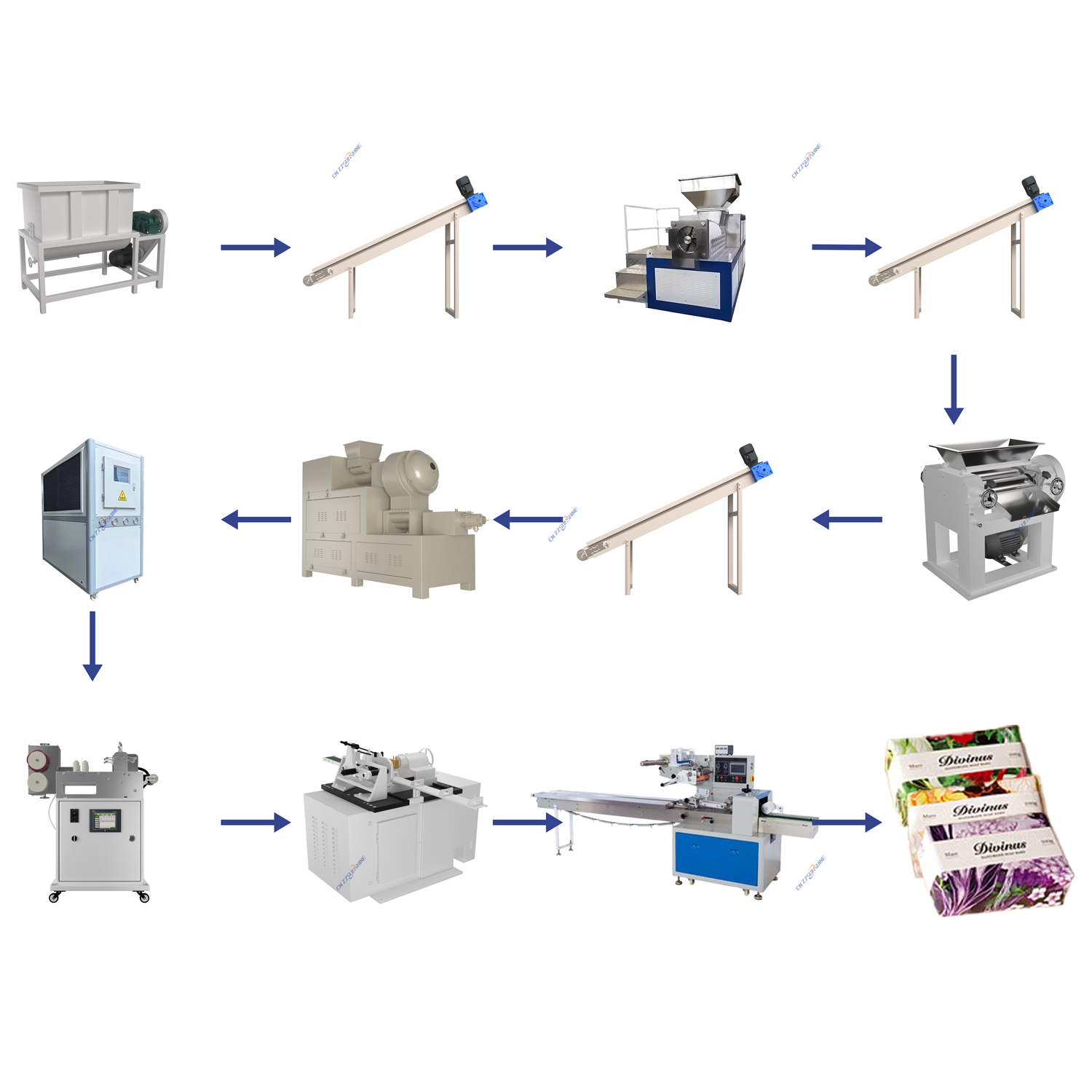

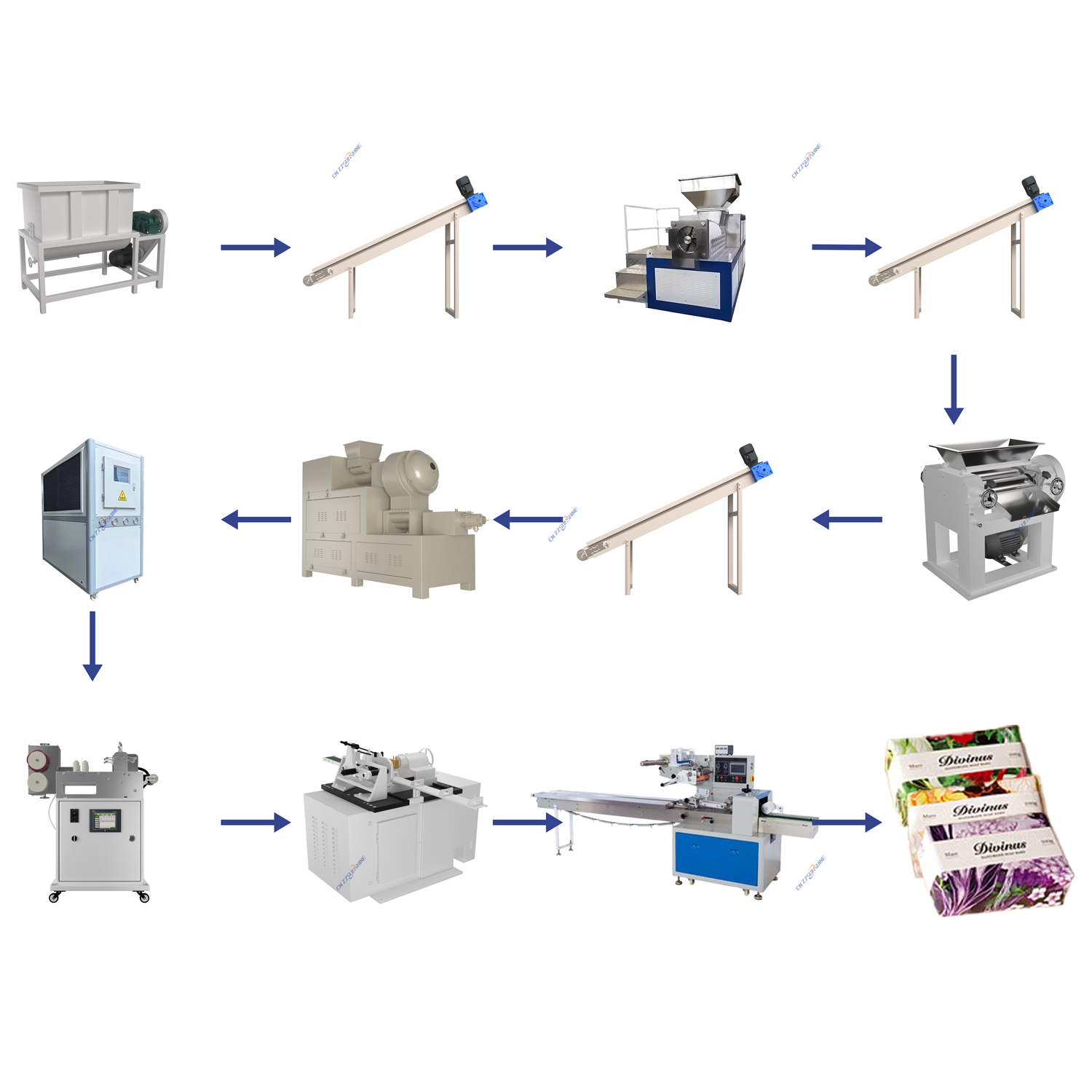

In today’s competitive industrial sector, the automatic soap production line has revolutionized how manufacturers create high-quality bar soaps with minimal human intervention. This integrated system typically includes a soap mixer for consistent blending of raw materials, ensuring homogeneity in chemical processing. Next, a vacuum plodder compresses the mixture to eliminate air bubbles, resulting in dense, durable bars for laundry or bath applications. The line then incorporates an electric washing soap cutter for precise slicing, which can be customized as a custom soap cutting machine to handle different soap sizes and shapes. For large-scale operations, such as a laundry bar soap production line or beauty soap making line, this automation boosts output by up to 50% while reducing waste. Key advantages include energy savings from components like a factory price industrial chiller for cooling machinery, and adaptability for OEM three roller grinding mill integration in cosmetics. Overall, investing in a reliable automatic soap production line not only cuts costs but also enhances product consistency, making it essential for modern factories aiming to meet global standards.

Innovations in Automatic Soap Production Line Efficiency

Innovations in Automatic Soap Production Line Efficiency

Posted Date:

By:

If you’re interested in our soap manufacturing equipment or would like to learn more about customized solutions tailored to your specific production needs, please fill out the inquiry form below with details such as your required capacity, soap type, level of automation, etc. As a professional manufacturer of soap machinery, we’re ready to provide you with comprehensive information and a competitive quotation—welcome to contact us!