The modern soap making production line is a marvel of engineering, transforming raw materials into finished bars with precision and efficiency. Achieving consistent quality, whether for laundry bar soap production lines or sophisticated toilet soap finishing lines, hinges on selecting the right integrated machinery and optimizing each stage of the process.

It begins with the **soap mixer** or **mixing machine**. This critical component ensures the uniform blending of fats, oils, lye, and additives. Industrial mixers for chemical processing must handle potentially abrasive or viscous mixtures, guaranteeing homogeneity before extrusion. The mixed paste then moves to the heart of refining: the **soap plodder machine for bar soap**. Typically, a twin-stage **vacuum plodder** is employed. The first stage compacts the paste, removing air pockets, while the second stage, under vacuum, further refines the texture and extrudes a continuous, dense log. This **vacuum plodder** step is vital for producing bars free of air bubbles and fissures, ensuring structural integrity and a smooth finish, essential for both **laundry soap making lines** and **bath soap making machines**.

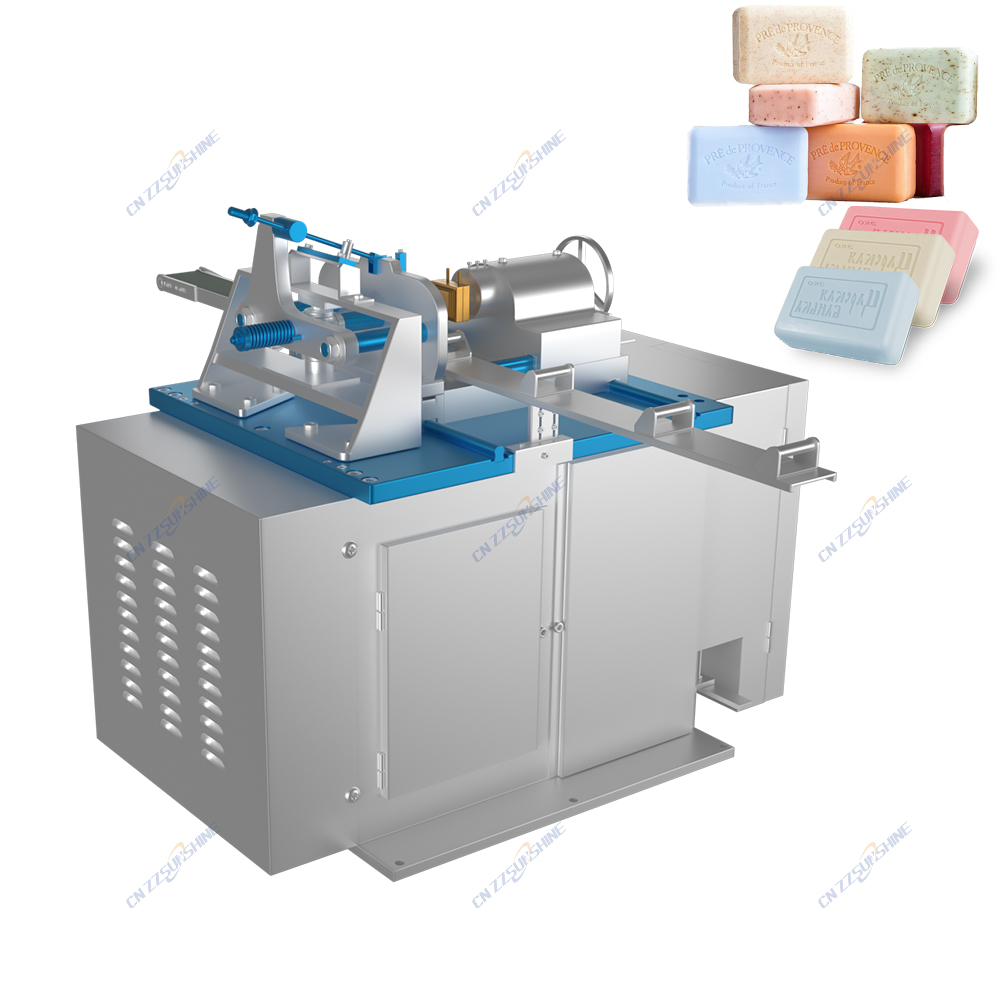

Following extrusion, the continuous soap log enters the cutting phase. Here, an **automatic block cutter machine** or an **electric washing soap cutter** slices the log into precise billets or individual bars. For high-volume operations, an **automatic soap production line** integrates seamlessly, feeding billets directly into stamping and embossing units. **Custom soap cutting machine** solutions are often required to achieve specific bar dimensions or unique shapes demanded by **beauty soap making line** products. Finally, the cut bars proceed through cooling tunnels and automated packaging systems.

Investing in a well-designed **soap making production line**, incorporating optimized **soap plodder** technology, reliable **mixing machines**, and precise **cutters**, translates directly to superior product quality, reduced waste, and increased throughput. Whether establishing a new **toilet soap finishing line** or upgrading an existing **laundry bar soap production line**, focusing on the synergy between these key components is paramount for success in the competitive soap manufacturing market.