Implementing a fully automatic soap production line transforms efficiency and consistency in bar soap manufacturing. This integrated system handles every stage, from raw material mixing to finished bar packaging, minimizing manual intervention and maximizing output.

The process begins with high-shear industrial mixers for chemical processing. These robust soap mixers ensure thorough blending of fats, oils, alkalis, and additives, achieving perfect saponification and homogeneous mixtures crucial for quality. The mixed soap base then moves to refining, often utilizing a three-roller mill for cosmetics-grade smoothness, especially critical for premium toilet soap finishing lines and beauty soap making lines where texture is paramount.

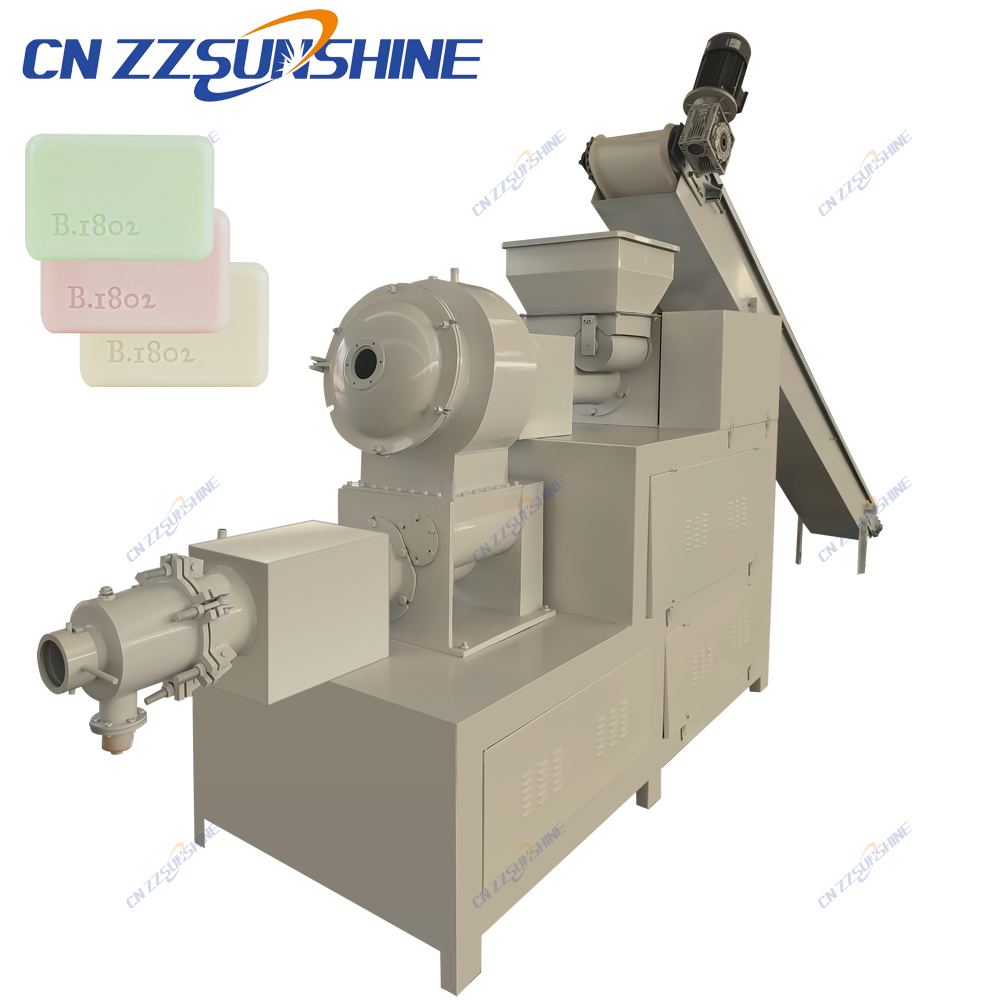

Next, the vacuum plodder becomes essential. This soap plodder machine compresses and de-aerates the soap mass under vacuum, creating a dense, uniform grain structure. Twin vacuum plodders in series are common in laundry bar soap production lines for optimal density. The continuous extrusion delivers a consistent soap log directly to the cutting stage.

Here, precision is key. An automatic soap cutter, often an electric washing soap cutter or custom soap cutting machine, slices the log into uniform blanks. Modern PLC-controlled cutters adjust dimensions instantly, accommodating diverse product ranges from bath soap making machines to laundry soap making lines. Some lines integrate an automatic block cutter machine for further shaping.

Finally, automated packing machines for food-grade standards handle wrapping and boxing. This seamless integration from the soap mixer through the soap plodder to the cutter ensures 24/7 operation with minimal downtime. Leading manufacturers offer complete laundry soap making line or toilet soap finishing line solutions, including OEM three-roller grinding mill options and factory price industrial chiller systems for cooling critical components.

Investing in a well-engineered automatic soap production line delivers significant ROI through reduced labor costs, consistent high-quality bars meeting strict cosmetic standards, minimal waste, and the flexibility to produce diverse soap types on a single, efficient platform. Partnering with experienced equipment suppliers ensures optimal line configuration and ongoing support.