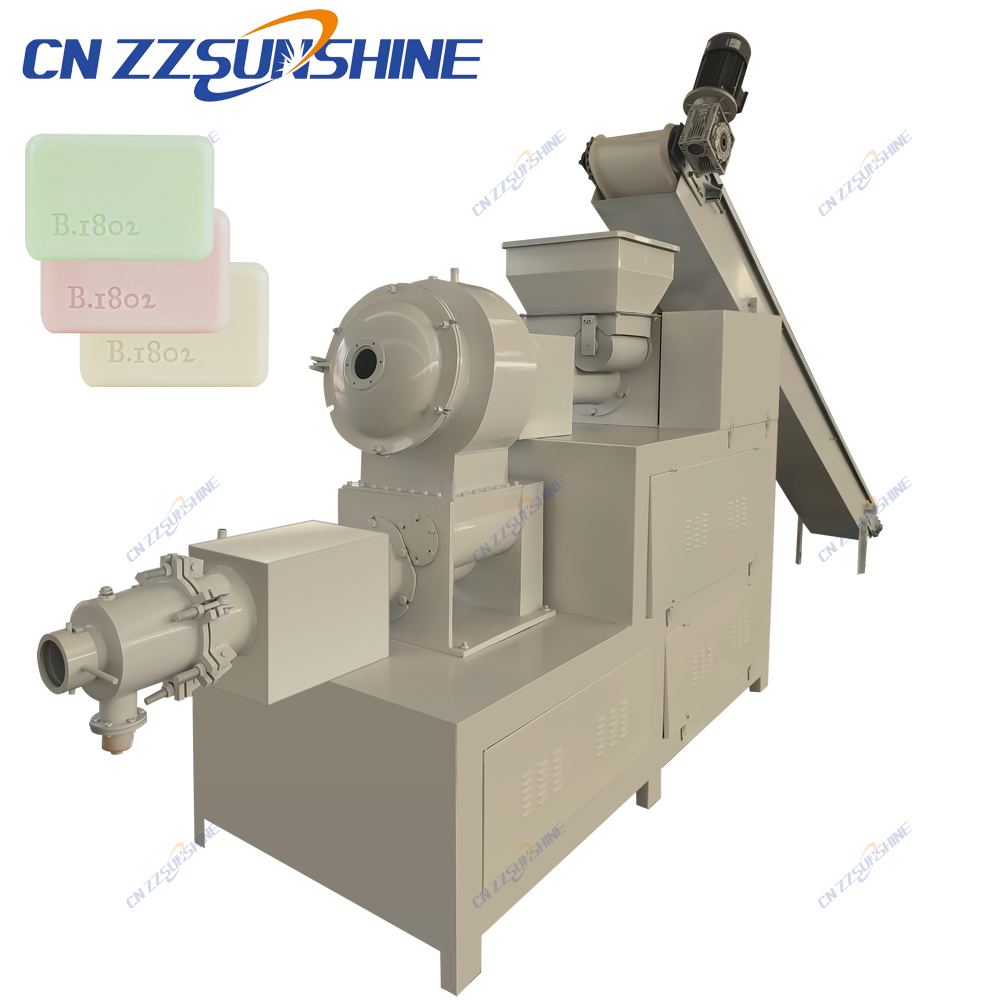

In today’s competitive soap manufacturing sector, integrating a streamlined soap making production line isn’t just a luxury—it’s essential for boosting output and slashing costs. As an industry veteran, I’ve witnessed firsthand how key components like a vacuum plodder and soap mixer transform raw materials into high-quality bars. For instance, a vacuum plodder removes air bubbles, ensuring denser, longer-lasting soap, while a soap mixer guarantees uniform blending of fragrances and additives, critical for consistent product quality. This setup is ideal for diverse applications, including a laundry bar soap production line or a beauty soap making line, where precision matters.

Beyond mixing, incorporating automated elements like a custom soap cutting machine or an electric washing soap cutter elevates efficiency. These tools handle precise sizing and sanitization, reducing manual errors and waste. In a toilet soap finishing line, such automation ensures smooth edges and hygiene compliance, appealing to global markets. Plus, for larger operations, an automatic soap production line with integrated controls minimizes downtime and labor expenses. Ultimately, investing in a well-designed system—featuring a soap plodder machine for bar soap and other tailored units—delivers tangible benefits: higher throughput, lower factory prices, and superior end products that meet stringent standards. By embracing these innovations, manufacturers can stay ahead, turning everyday challenges into profitable opportunities.