The landscape of commercial soap production has undergone a significant transformation. Gone are the days of purely manual, batch-dependent processes fraught with inconsistency and high labor costs. Today, achieving competitive scale and quality demands a sophisticated, integrated **soap making production line**. This cohesive system harmonizes specialized machinery to streamline operations from raw material handling to finished bar output.

At the heart of any robust **laundry bar soap production line** or **toilet soap finishing line** lies precision mixing. A high-shear **industrial mixer for chemical processing** ensures the homogeneous blending of fats, oils, alkalis, and additives, forming the essential soap base crucial for final product stability and performance. This initial stage sets the foundation for quality.

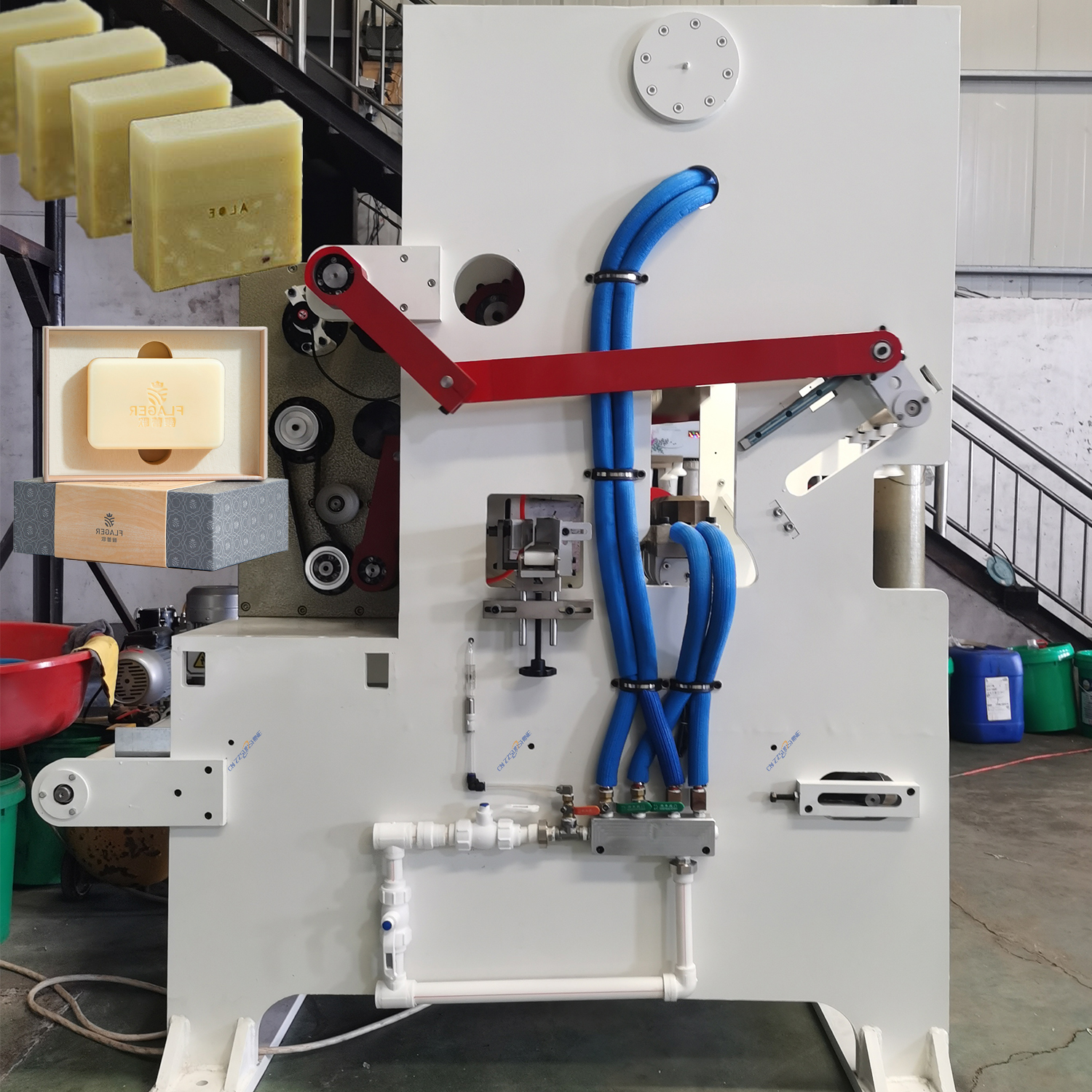

Following mixing, the molten soap base undergoes critical refinement and forming. This is where the **soap plodder machine for bar soap**, particularly advanced **vacuum plodder** units, prove indispensable. These machines work the soap mass under vacuum, removing trapped air pockets that cause bubbles and imperfections. The plodder then continuously extrudes a dense, uniform log of soap, ready for sizing. The efficiency gains from a reliable **soap plodder** are substantial, directly impacting throughput and bar density.

Next, automation takes center stage with the **automatic soap cutting machine**. Whether a simple **cutter** or a sophisticated **electric washing soap cutter**, these devices slice the extruded soap log into precise, individual slugs or bars with minimal waste and maximum speed, far surpassing manual methods. For specialized shapes or **beauty soap making line** requirements, **custom soap cutting machine** solutions offer tailored precision.

The final stages involve finishing and packing. A **toilet soap finishing line** typically includes stamping, polishing, and cooling conveyors to achieve the desired aesthetic and feel. Finally, an **automatic packing machine for food**-grade standards ensures hygienic, efficient wrapping and boxing of the finished bars, ready for distribution. Integrating an **industrial chiller for machinery** is often vital for process cooling and maintaining optimal equipment temperatures, especially during high-volume runs.

Leading **China feed processing machine supplier** companies have expanded expertise into soap machinery, offering complete **automatic soap production line** solutions – from the initial **soap mixer** to the final packed bar – at competitive **factory price industrial chiller** points. This integrated approach, combining core technologies like the **vacuum plodder** and **automatic soap cutting machine** within a unified **soap making production line**, is the cornerstone of modern, efficient, and profitable soap manufacturing for both **laundry soap making line** and premium **bath soap making machine** applications.