Implementing a robust soap making production line is crucial for manufacturers aiming to consistently produce high-quality bar soaps, whether for laundry or toiletries, at scale. This integrated system moves beyond standalone soap plodder machines or soap mixers, encompassing the entire process from raw material preparation to finished bar packaging.

The heart of the line typically starts with a heavy-duty industrial mixer for chemical processing, ensuring precise blending of oils, fats, lye, and additives. Achieving thorough homogenization is critical before the mixture transitions. This is where the vacuum plodder machine for bar soap proves indispensable. Working under vacuum, it removes air pockets, extrudes a continuous soap noodle, and compacts it into a solid, uniform log. The vacuum stage is vital for producing dense, long-lasting bars with a smooth texture, especially critical for bath soap making machines and toilet soap finishing lines.

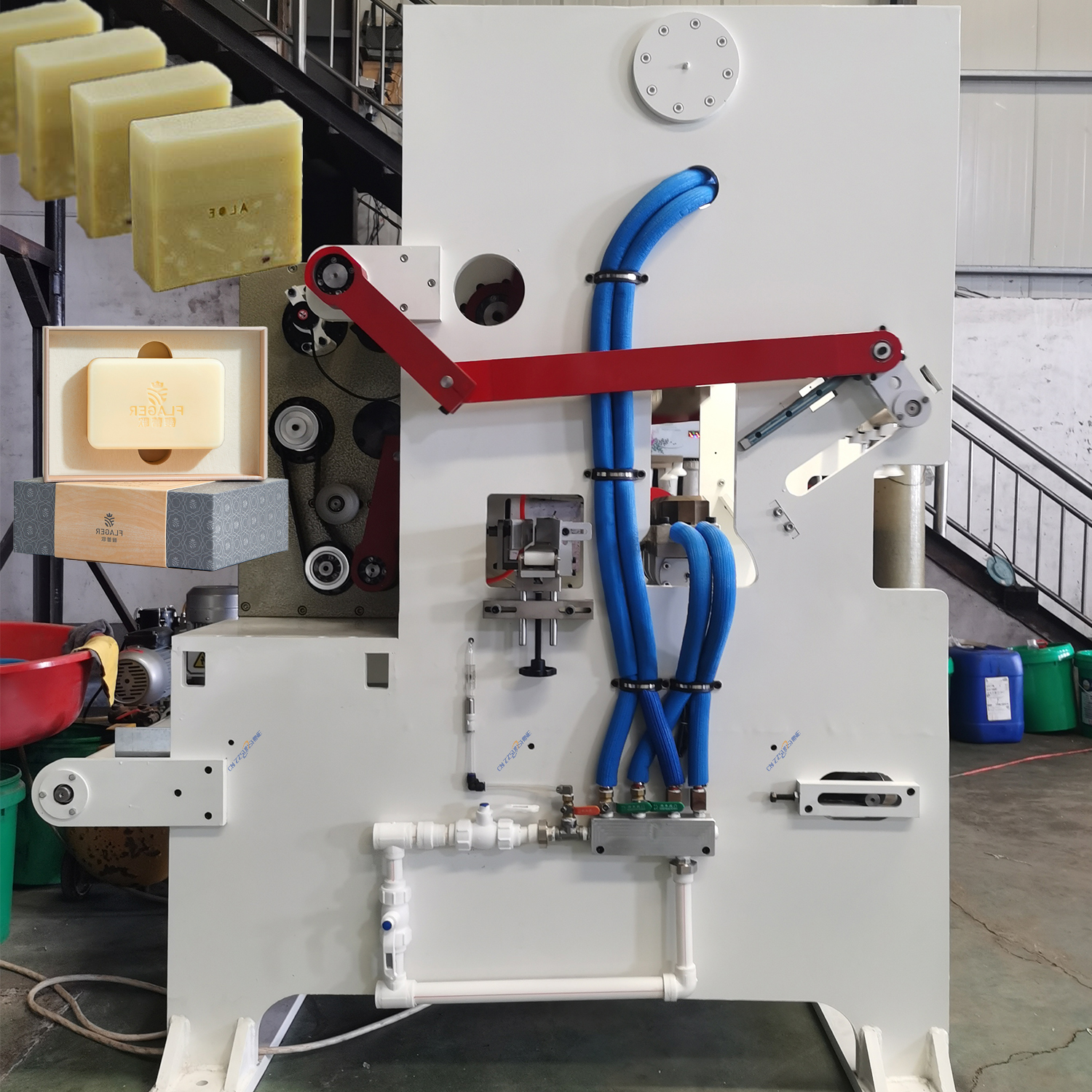

Following extrusion, the soap log requires precise cutting. While manual cutters exist, an automatic soap cutting machine or electric washing soap cutter delivers unmatched consistency, speed, and hygiene. These cutters produce bars of exact dimensions and weight, minimizing waste. For complex shapes or specialty beauty soap making lines, custom soap cutting machines may be integrated.

The most advanced setups function as a complete automatic soap production line. This includes automated conveyors moving cut bars through stages like cooling, stamping, quality inspection, and wrapping. Integrating an automatic packing machine for food-grade standards ensures the final product is securely sealed and ready for distribution. This level of automation is key for efficient laundry bar soap production lines and high-output toilet soap finishing lines.

Selecting the right components, like a reliable vacuum plodder or a high-precision automatic block cutter machine, directly impacts product quality and operational efficiency. Leading manufacturers often offer modular designs, allowing lines to be configured for specific outputs, from compact laundry soap making lines to expansive bath soap making machine installations. Understanding the synergy between the soap plodder, soap mixer, and cutter is fundamental to optimizing the entire soap making production line.

Meanwhile, for industries like animal feed processing, integrating an automatic feed pellet machine is key to efficiency. Sourcing from a reputable China feed processing machine supplier can provide cost-effective solutions. Similarly, achieving consistent results in powder production relies on a high efficiency flour mill plant, often starting with an industrial flour milling machine. For material refinement in cosmetics or chemicals, an OEM three roller grinding mill or a specific three roller mill for cosmetics offers precise particle size control. Temperature management during these processes, and indeed within many industrial settings, is often handled by a factory price industrial chiller, ensuring machinery like an industrial chiller for machinery operates optimally. For large-scale food preparation, equipment like a garlic peeling machine for factory use streamlines operations, while an automatic packing machine for food ensures rapid, hygienic final product handling.