Investing in a robust soap making production line is crucial for manufacturers aiming to scale output, ensure consistent quality, and maintain competitive factory pricing. Whether you’re producing laundry bar soap or premium toilet soap, the integration of specialized machinery streamlines operations from raw material handling to finished product packaging.

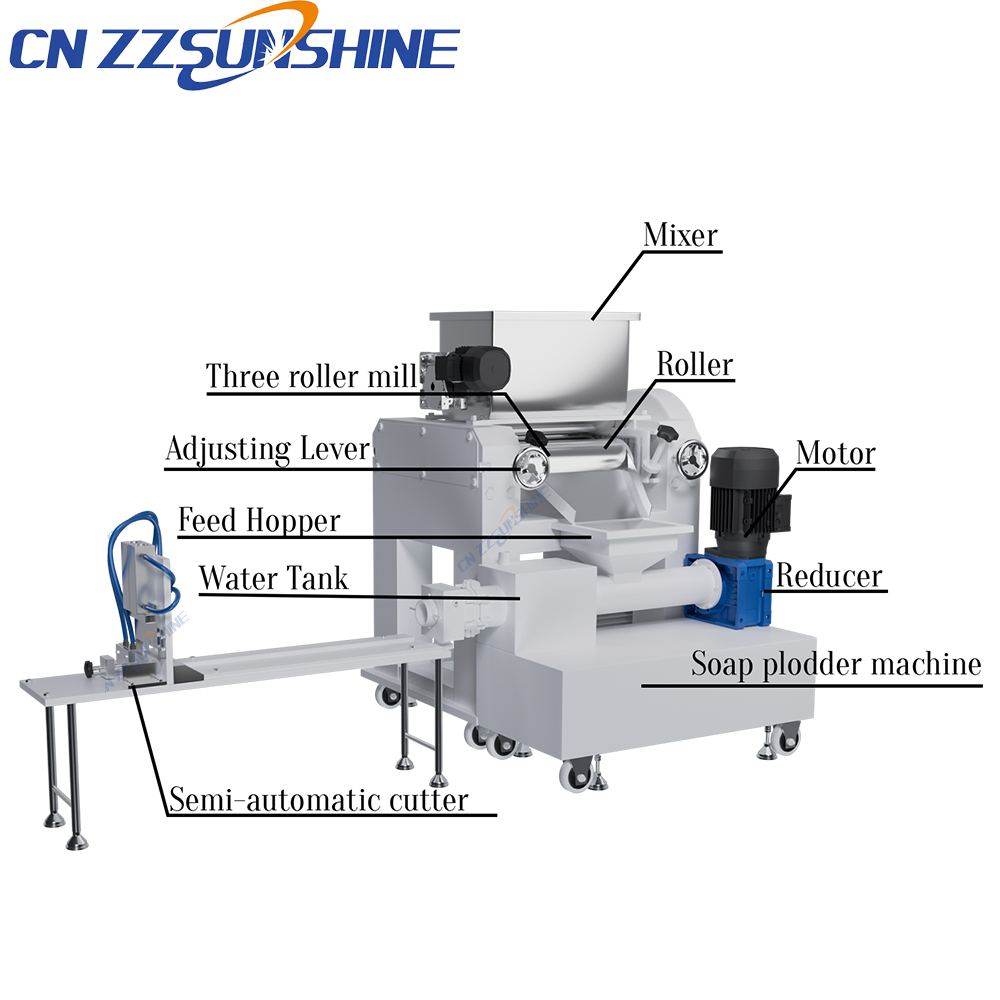

The core process begins with precise ingredient blending. A high-capacity industrial mixer for chemical processing ensures homogeneous mixing of fats, oils, lye, and additives, forming the initial soap base. This mixture then undergoes refining, often using a three roller mill for cosmetics-grade smoothness, essential for beauty soap making lines. The refined soap paste is fed into a critical component: the vacuum plodder. This soap plodder machine for bar soap compacts the mixture under vacuum, removing air pockets to create a dense, uniform extruded log. Vacuum plodding is vital for preventing cracking and ensuring bar integrity in both laundry soap making lines and bath soap production.

Following extrusion, the continuous log requires precise cutting. An automatic soap cutting machine, or specifically an electric washing soap cutter, delivers clean, uniform bar sizes at high speed, minimizing waste. For operations requiring flexibility, a custom soap cutting machine accommodates various bar dimensions. The cut bars then proceed to stamping, cooling, and finishing stages – the toilet soap finishing line – where they are shaped, imprinted, cooled efficiently using an industrial chiller for machinery, and polished.

True efficiency is achieved by integrating these components into a seamless automatic soap production line. Automation, including automatic packing machines for food-grade wrapping, reduces labor costs and human error. Partnering with a reliable OEM for critical components like the three roller grinding mill or vacuum plodder ensures machinery longevity and access to technical support. Optimizing each segment – from the soap mixer and plodder to the cutter – transforms a collection of machines into a high-output, cost-effective production asset capable of meeting diverse market demands.