Implementing an automatic soap production line is the definitive step for manufacturers aiming to scale output while maintaining stringent quality control. These integrated systems eliminate manual handling bottlenecks inherent in batch processing, delivering a continuous, high-volume flow of finished bars, whether for laundry bar soap production lines or premium toilet soap finishing lines.

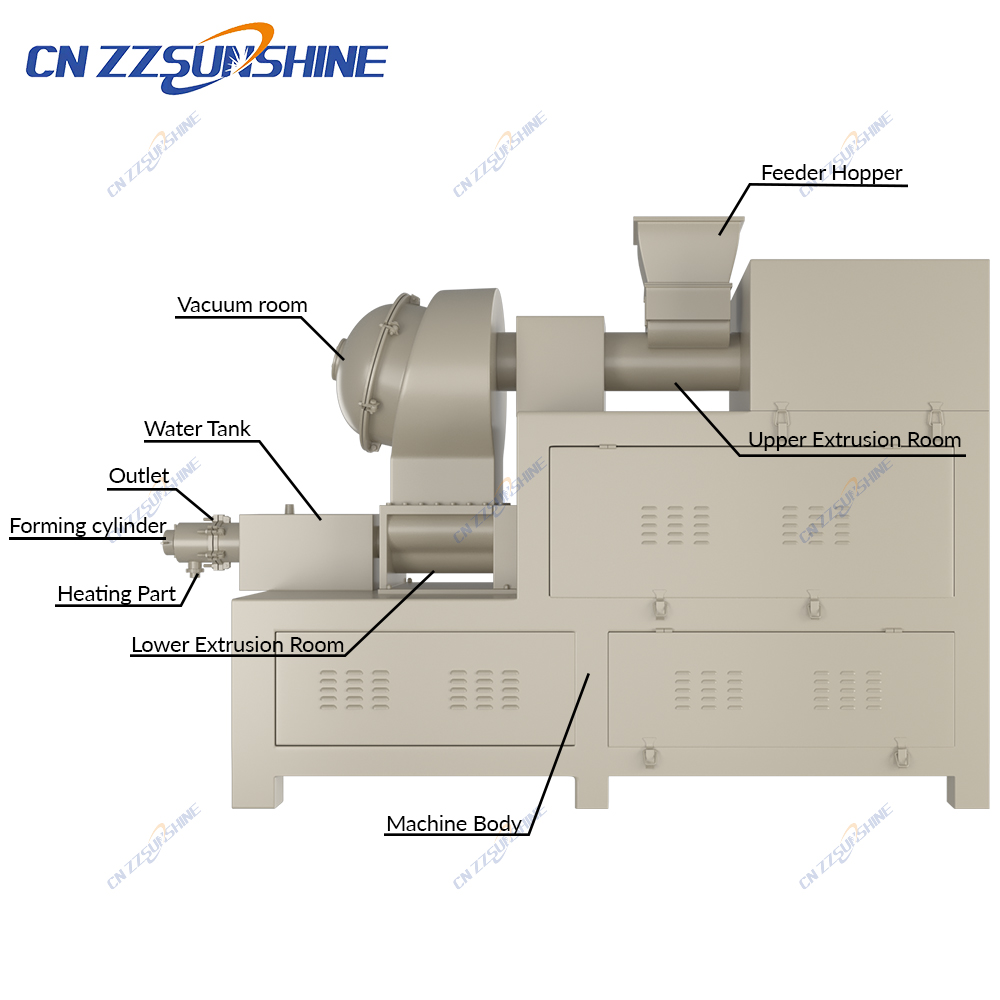

The core process begins with the soap mixer. Industrial mixers for chemical processing handle the precise blending of fats, oils, caustic soda, additives, and fragrances under controlled conditions. This homogeneous mixture is then fed into the heart of the line: the vacuum plodder. This critical component compresses and extrudes the soap mass under vacuum, removing air pockets that cause cracking or crumbling. The result is a dense, continuous log of consistent texture and composition.

Downstream, the extrusion process relies on specialized soap plodder machines for bar soap. Modern vacuum plodder technology ensures optimal density and smoothness. The continuous log is then precisely cut by high-speed cutter units. Electric washing soap cutters offer clean, hygienic separation with minimal waste, while custom soap cutting machines can be configured for specific bar weights, shapes, or embossing patterns for bath soap making machines or beauty soap making lines.

Integrating an industrial chiller for machinery is vital. These factory price industrial chillers regulate temperatures throughout the line, particularly crucial for cooling extrusion heads and cutters, ensuring dimensional stability and precise cutting edges. Modern PLC controls govern the entire automatic soap production line, synchronizing the soap mixer, vacuum plodder, cutter, and conveyors. This automation allows real-time monitoring of parameters like pressure, temperature, and throughput, enabling rapid adjustments and consistent product quality. OEM three roller grinding mills might also be incorporated upstream for specific additive incorporation in niche applications.

The shift from semi-automatic setups to a fully automatic soap production line yields transformative benefits. Dramatic increases in output per shift, significant labor cost reduction, minimized material waste, enhanced worker safety by limiting direct contact with raw materials, and unparalleled batch-to-batch consistency are the hallmarks. Whether producing robust laundry soap or delicate toilet bars, this integrated approach, combining a reliable soap plodder machine, efficient mixing machine, and precise cutter, delivers unmatched operational efficiency and product integrity.