Beyond Basic Lather: Unlock Efficiency with Advanced Soap Manufacturing Equipment

Crafting high-quality soap bars consistently requires more than just good ingredients; it demands precision machinery designed for reliability and output. Whether you’re scaling up production or refining your existing line, investing in the right soap making machine, soap mixer, and mixing machine is paramount.

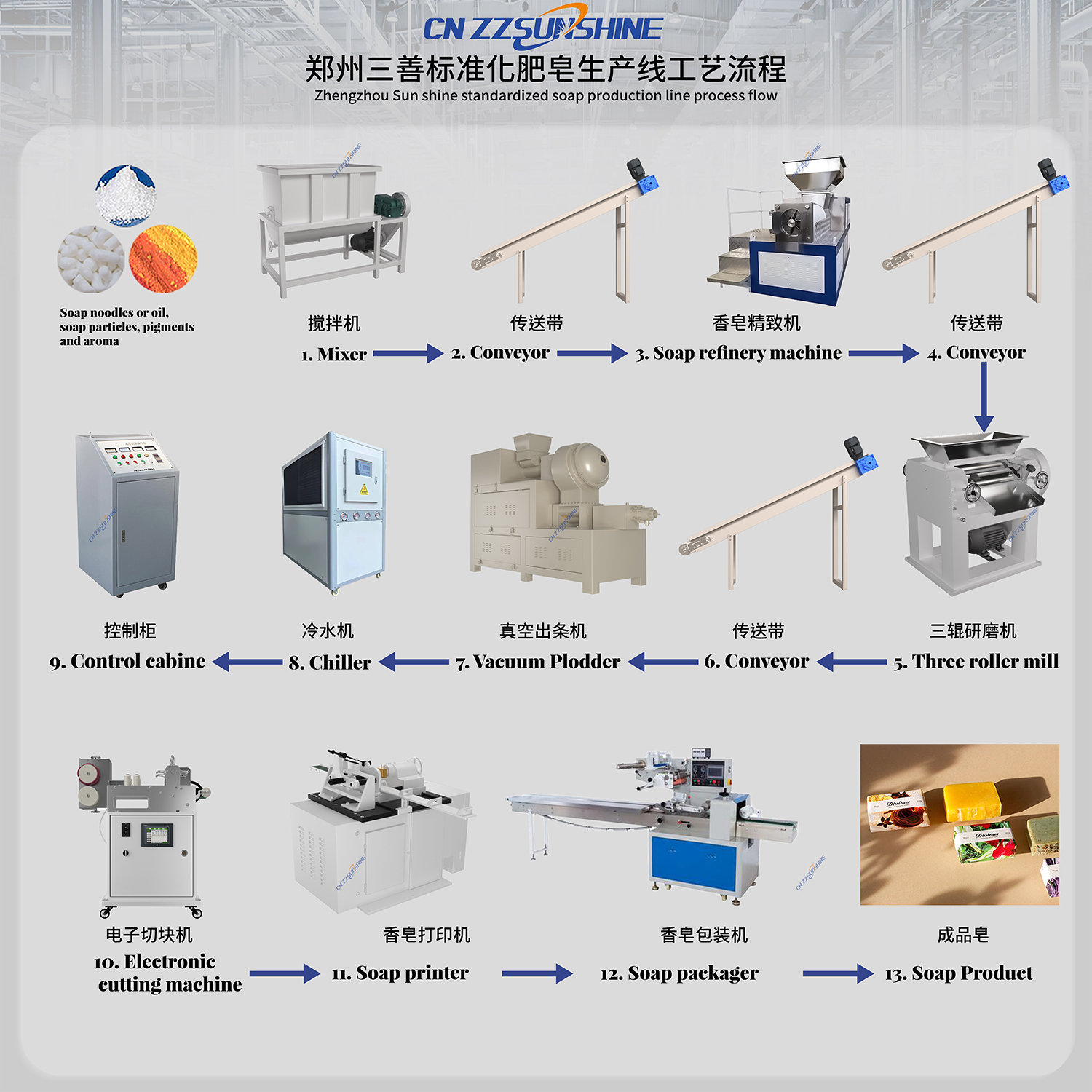

At the heart of any efficient operation lies a robust soap mixer. This critical component ensures uniform blending of fats, alkalis, and additives, laying the foundation for a superior product. Pair this with a high-performance soap plodder machine for bar soap, particularly a modern vacuum plodder, and you achieve the necessary extrusion and de-aeration crucial for producing dense, long-lasting bars with an appealing finish. This combination is vital for both laundry soap making line and toilet soap finishing line operations.

Achieving consistent sizing and aesthetics is the next step. Moving beyond basic cutter options, integrating an automatic block cutter machine or a custom soap cutting machine significantly boosts throughput and minimizes waste. Options range from electronic cutting machine to pneumatic cutting machine, allowing for tailored solutions that fit specific bar dimensions and production volumes. For intricate shapes or artisanal batches found in a beauty soap making line, specialized cutting becomes indispensable.

For comprehensive solutions, consider an integrated automatic soap production line. Such systems seamlessly combine mixing, refining (potentially including an OEM three roller grinding mill for fine texture), extrusion via a soap plodder, cutting, and often downstream processes like stamping with an automatic printer or soap stamping machine, and packaging using a film packaging machine. This end-to-end automation, from raw materials to finished, wrapped bars, is key for maximizing the high yield potential of your soap making production line, whether it’s a large-scale laundry bar soap production line or a more compact mini soap production line.

Choosing the right machinery partners – from core soap making machines like mixers and plodders to auxiliary equipment – directly impacts your product quality, operational efficiency, and bottom line. Focus on equipment designed for durability, precision, and scalability to meet growing market demands effectively.