The Essential Mini Soap Grinder: Elevating Your Toilet Soap Finishing Line

In the intricate world of soap manufacturing, achieving that perfect, luxurious texture for toilet soap isn’t just desirable—it’s essential. This is where specialized equipment like the Mini Soap Grinder Grinding Machine Soap Three Roller Milling Machine Automatic for Toilet Soap becomes indispensable. While often a smaller component within a larger automatic soap production line, its role in refining soap quality is critical.

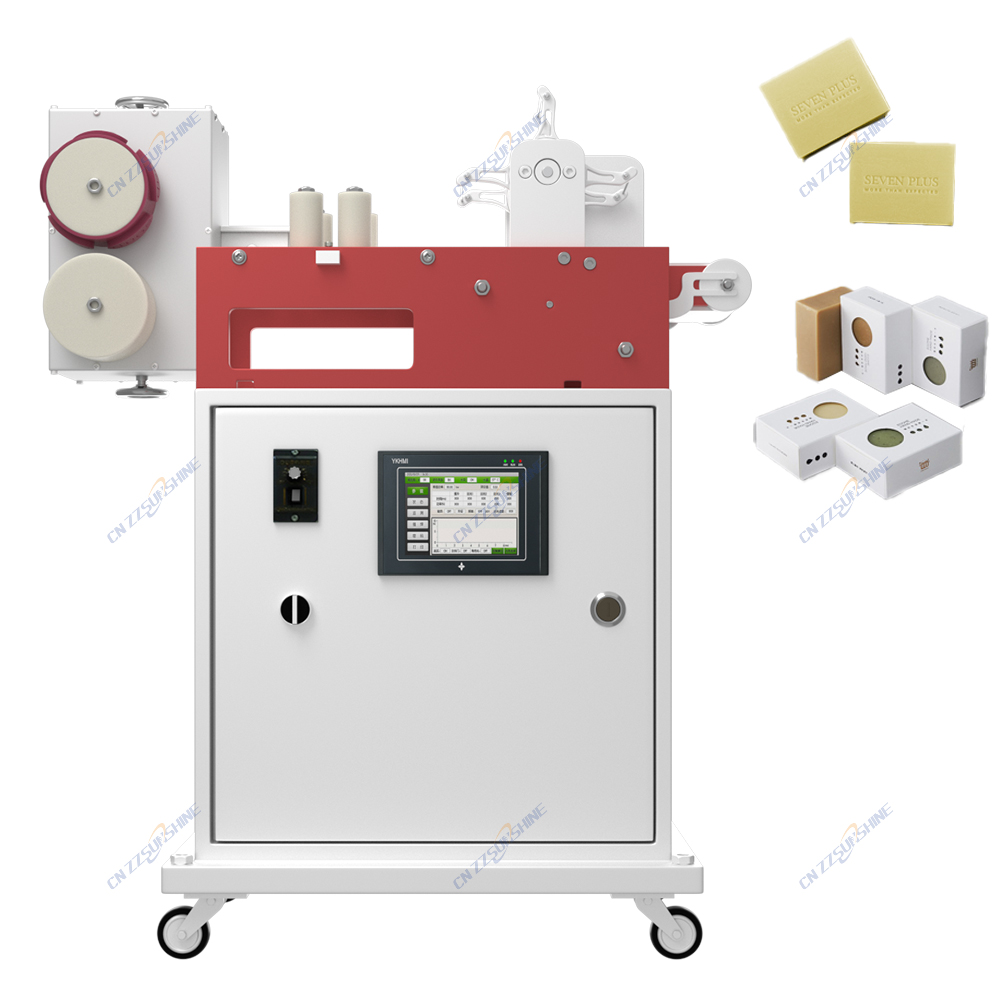

This compact yet robust machine leverages the proven technology of a three roller grinding mill. Its purpose is precise: to finely grind soap noodles or flakes, ensuring a smooth, homogenous paste ready for extrusion and stamping. The automatic operation minimizes manual handling, enhancing hygiene and consistency—key factors in producing high-quality toilet soap. For businesses starting out or those needing a dedicated unit for specific batches, a mini soap production line incorporating this grinder offers flexibility without compromising on finish quality.

The effectiveness of the three roller milling machine lies in its design. Rollers rotate at different speeds, creating shear forces that break down soap particles. This milling process is vital, especially when paired with a soap plodder machine for bar soap later in the toilet soap finishing line. Well-milled soap ensures the vacuum plodder can effectively remove air bubbles and form a dense, uniform log, ready for cutting by an electric washing soap cutter or pneumatic cutting machine.

Integrating this grinder seamlessly into your existing soap making production line is straightforward. It acts as the bridge between initial mixing (handled by a soap mixer or mixing machine) and the final forming stages involving soap plodder units and soap stamping machines. Whether part of a larger laundry soap making line, a bath soap making machine setup, or a dedicated beauty soap making line, the principle remains the same: finer milling leads to superior end products.

For manufacturers seeking tailored solutions, options like an OEM three roller grinding mill allow customization to specific throughput or soap formulation needs. When combined with other key components—be it an automatic block cutter machine, a custom soap cutting machine, or packaging units like a film packaging machine—this mini grinder becomes a cornerstone of efficiency.

Ultimately, incorporating an automatic three roller milling machine into your toilet soap finishing line is an investment in product excellence. It ensures the smoothness consumers expect, making it a smart addition to any automatic soap production line, from compact mini soap production line setups to full-scale operations. Elevate your soap quality; refine your process with the right milling technology.