Beyond the Basics: Your Complete Soap Production Solution

In today’s competitive soap market, efficiency, consistency, and customization are paramount. Manufacturers seeking to elevate their production capabilities need more than just individual machines; they require a cohesive, high-performing soap making production line. This is where integrated solutions shine, offering a seamless journey from raw materials to finished, market-ready products.

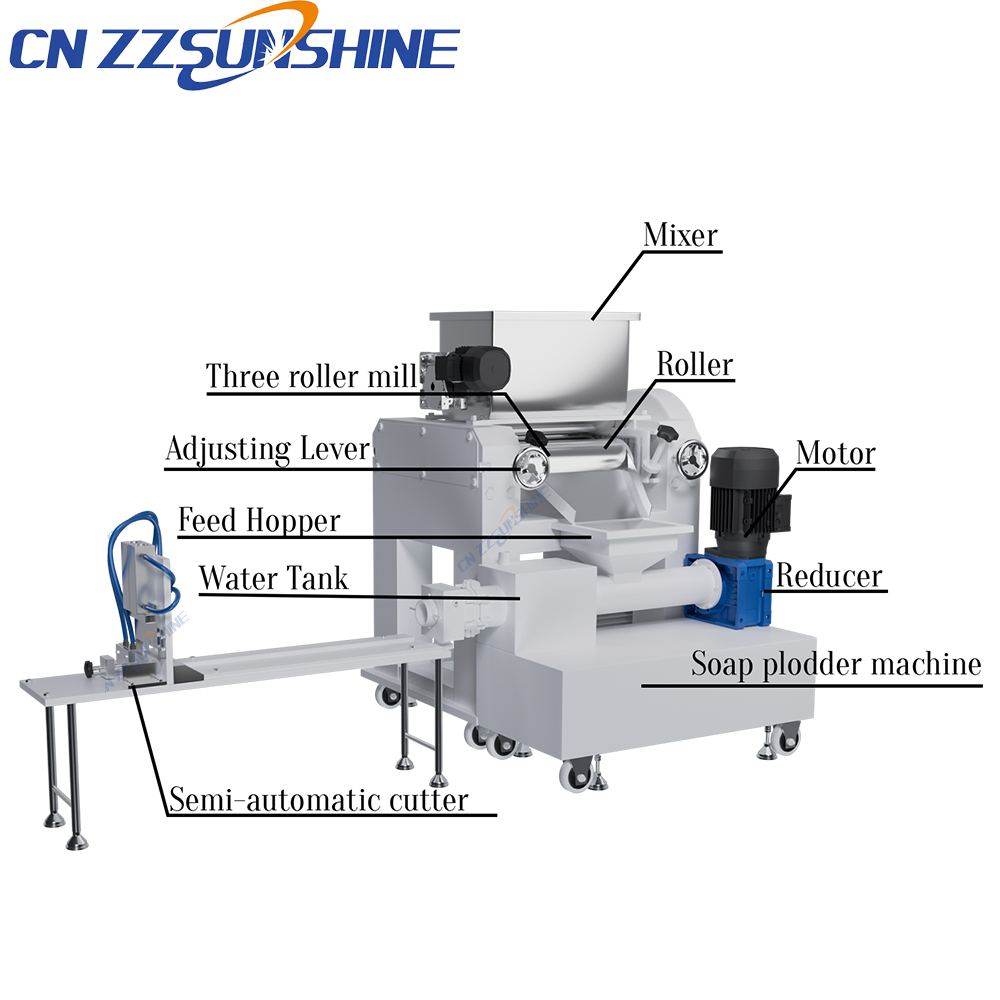

Imagine a system designed for versatility and precision. At its core might be a robust soap plodder machine for bar soap, perhaps a sophisticated Vacuum plodder, meticulously refining the soap base to ensure optimal texture and eliminate air bubbles. Paired with a powerful soap mixer or Mixing machine, this stage guarantees uniform blending of ingredients, crucial for quality whether producing laundry soap or luxurious beauty soap.

The true magic of a modern line lies in its finishing capabilities. A Fully Automatic Soap Printer revolutionizes decoration, applying intricate designs, logos, or information at high speeds with unparalleled accuracy, eliminating the bottlenecks of Semi-automatic Printers. Complementing this is a Soap Molding Machine With Customized Molds Included. This flexibility allows manufacturers to effortlessly switch between diverse shapes and sizes – think classic rectangles, elegant ovals, or unique branded contours – all achievable with bespoke molds tailored to specific requirements. The output? Perfectly formed soap bars, ready for the next stage.

Efficient sizing is handled by advanced cutting technology. Options range from Manual Cutting Machines for lower volumes to sophisticated Automatic block cutter machines or Pneumatic Cutting Machines that deliver consistent, precise bars with minimal waste. For final branding, a Soap Stamping Machine imparts logos or essential details cleanly and reliably.

A truly Complete Soap Machine solution extends beyond bar creation. Integration with a Film Packaging Machine ensures hygienic and attractive wrapping, while separate lines like Washing Liquid Production Equipment can diversify offerings. Whether you’re scaling up with a full Automatic soap production line or starting smaller with a Mini Soap Production Line, the integration of these specialized components – the soap plodder, mixer, printer, custom soap cutting machine, and molder – creates a powerhouse of productivity.

Investing in a cohesive system, incorporating a soap making machine for molding with customized options, an automatic printer, and complementary cutting and finishing equipment, is an investment in the future. It streamlines operations, enhances product quality, enables brand differentiation, and ultimately drives growth in the demanding world of soap manufacturing.