Beyond the Mold: The Power of Fully Automatic Soap Printing & Production

The soap industry, whether catering to the demanding hygiene standards of laundry bar soap production lines or the aesthetic allure of beauty soap making lines, thrives on efficiency and consistency. At the heart of modern manufacturing lies the Fully Automatic Soap Printer, a cornerstone of contemporary Solid Soap Production Machines. This advanced technology represents a significant leap from traditional methods, integrating seamlessly within a soap making production line to deliver unparalleled precision and output.

Understanding the Automated Soap Production Journey

A comprehensive Automatic Soap Production Line is more than just a single machine; it’s a symphony of specialized equipment working in unison. The process typically begins with the fundamental mixing stage. Here, a robust soap mixer or mixing machine blends raw materials – fats, oils, alkalis, and additives – into a homogenous soap base. This mixture is then refined. An OEM three roller grinding mill might be employed for fine particle dispersion and smoothing, particularly crucial for high-quality toilet soaps.

The refined soap mass then moves to a soap plodder machine for bar soap, often a Vacuum plodder. This critical component kneads, compresses, and extrudes the soap under vacuum conditions, removing air pockets to create a dense, uniform log or billet essential for premium bar quality. Following extrusion, the continuous soap log requires precise sizing. An automatic block cutter machine slices the log into manageable blocks or slugs, ready for the final shaping stages.

The Star Performer: The Fully Automatic Soap Printer

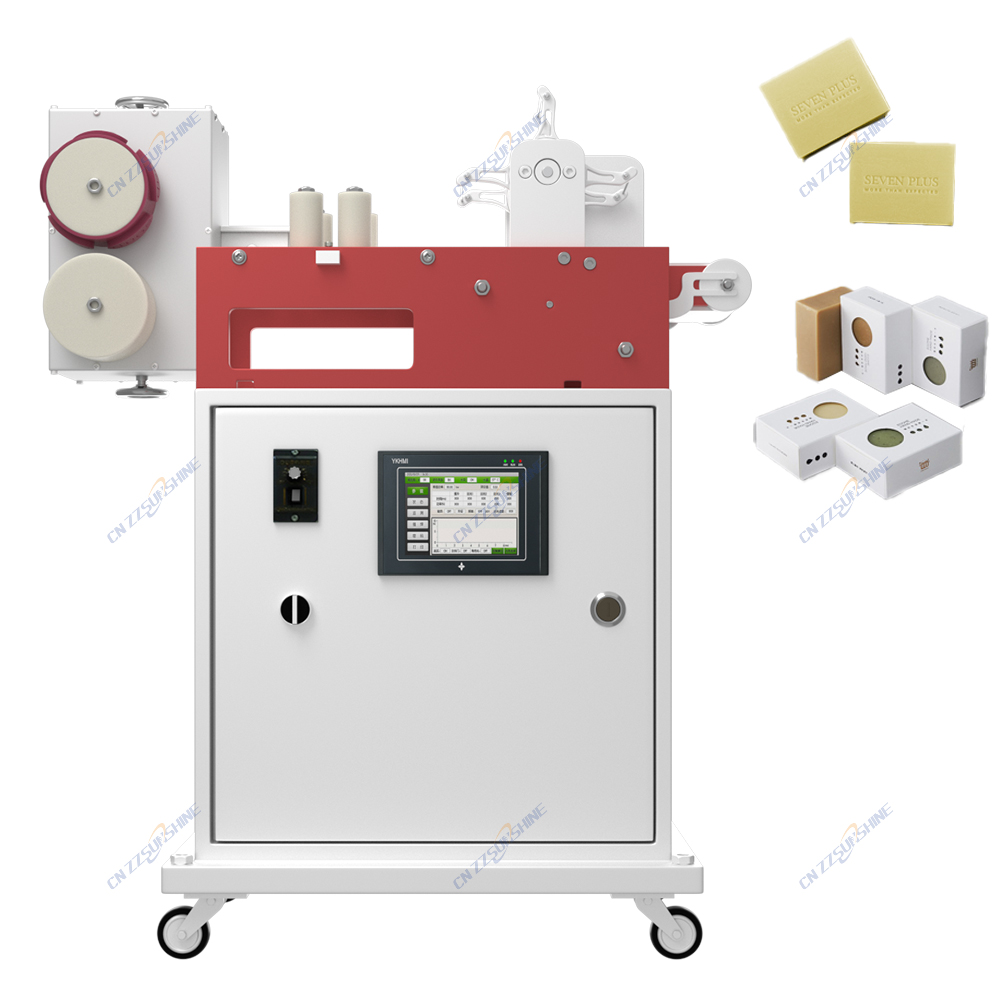

This is where the Fully Automatic Soap Printer (also frequently termed an Automatic Printer) takes center stage. Unlike older Semi-automatic Printers or labor-intensive manual methods, this machine automates the crucial final steps: stamping and cutting.

Stamping: The machine incorporates a Soap Stamping Machine mechanism. Pre-cut soap slugs are fed into the printer, where they are automatically pressed into molds under significant force. This action simultaneously imparts the desired shape (round, oval, rectangular) and embosses the brand logo, product name, or any decorative pattern onto the soap surface with remarkable clarity and consistency. The precision ensures every bar looks identical, reinforcing brand identity.

Cutting: Integrated seamlessly with the stamping process is the cutting function. Modern automatic printers utilize sophisticated cutting mechanisms – be it an Electronic Cutting Machine or Pneumatic Cutting Machine – to slice the stamped soap into individual bars immediately after molding. This eliminates the need for separate Manual Cutting Machines or custom soap cutting machines at this stage, streamlining the workflow significantly. Some lines might still employ an Electric washing soap cutter earlier in the process for log sizing, but the printer handles the final bar separation.

Beyond Stamping: The Complete Finishing Line

After exiting the Fully Automatic Soap Printer, the newly stamped and cut bars proceed to drying and packaging. A toilet soap finishing line or laundry soap making line will typically include drying tunnels to reduce moisture content before the bars are ready for wrapping. Packaging options vary, from traditional cartons to modern Film Packaging Machines that offer efficiency and attractive presentation. For liquid products, separate Washing Liquid Production Equipment would be utilized.

Why Automation Wins: Benefits for Manufacturers

Investing in an Automatic Soap Production Line centered around a Fully Automatic Soap Printer offers compelling advantages:

1. Unmatched Efficiency: Dramatically increases production speed compared to semi-automatic or manual operations.

2. Consistent Quality: Ensures every single bar has identical shape, weight, and stamping detail, enhancing brand reputation.

3. Reduced Labor Costs: Automates the most labor-intensive steps (stamping and cutting), lowering operational expenses.

4. Scalability: Designed for high-volume production, allowing businesses to grow without proportionally increasing manual labor.

5. Hygiene & Safety: Minimizes direct human contact with the product during finishing, improving hygiene standards and operator safety.

Finding the Right Fit: From Mini to Major

Solutions exist for businesses of all sizes. A Mini Soap Production Line might incorporate a compact automatic printer suitable for smaller batches or artisanal producers. Larger facilities require robust, high-speed lines capable of handling massive volumes for laundry or bath soap (bath soap making machine). The key is choosing equipment – the soap plodder, soap mixer, cutter, and crucially, the Fully Automatic Soap Printer – that aligns with specific production goals, desired bar types (toilet, laundry, beauty), and output requirements.

Conclusion

The Fully Automatic Soap Printer is far more than just a stamping device; it’s the intelligent core of modern Solid Soap Production Machines. By integrating precise stamping and cutting into one efficient unit, it drives the productivity and quality standards demanded by today’s competitive market. Whether part of a comprehensive laundry bar soap production line or a sophisticated beauty soap making line, embracing this automation technology is essential for manufacturers aiming for efficiency, consistency, and growth in the dynamic world of soap production. Investing in the right soap making machine technology is an investment in the future of your brand.