Unleash Efficiency: The Power of Fully Automatic Soap Production

Imagine transforming raw materials into beautifully finished soap bars with minimal manual intervention. That’s the reality offered by modern, fully automatic soap production technology. For manufacturers aiming to scale operations, enhance consistency, and boost profitability, investing in an integrated soap making production line is no longer a luxury—it’s a strategic necessity. At the heart of such a line lie critical machines like the Fully Automatic Soap Printer, Solid Soap Production Machines, and advanced Mixing Machines with Electric Heating.

The Precision Touch: Fully Automatic Soap Printers

Gone are the days of inconsistent stamping or labor-intensive manual printing. The Automatic Soap Printer represents a leap forward in finishing quality and efficiency. These sophisticated machines take cut soap bars and apply brand logos, designs, or essential information with impeccable accuracy and speed. Unlike semi-automatic printers or manual methods, they integrate seamlessly into continuous production flows. The result? Perfectly branded bars, batch after batch, with significantly reduced labor costs and zero risk of human error in placement. This consistency is vital for brand reputation and meeting retailer specifications.

Core Components: Building the Perfect Bar

Producing high-quality solid soap requires robust core machinery. This typically includes:

1. The Mixer with Electric Heating: The foundation starts here. A high-performance soap mixer, often featuring electric heating, ensures precise temperature control during the saponification and mixing phases. This is crucial for achieving thorough blending of fats, oils, lye, and additives, guaranteeing a homogenous mixture essential for bar quality and stability. Electric heating offers superior control and efficiency compared to older methods.

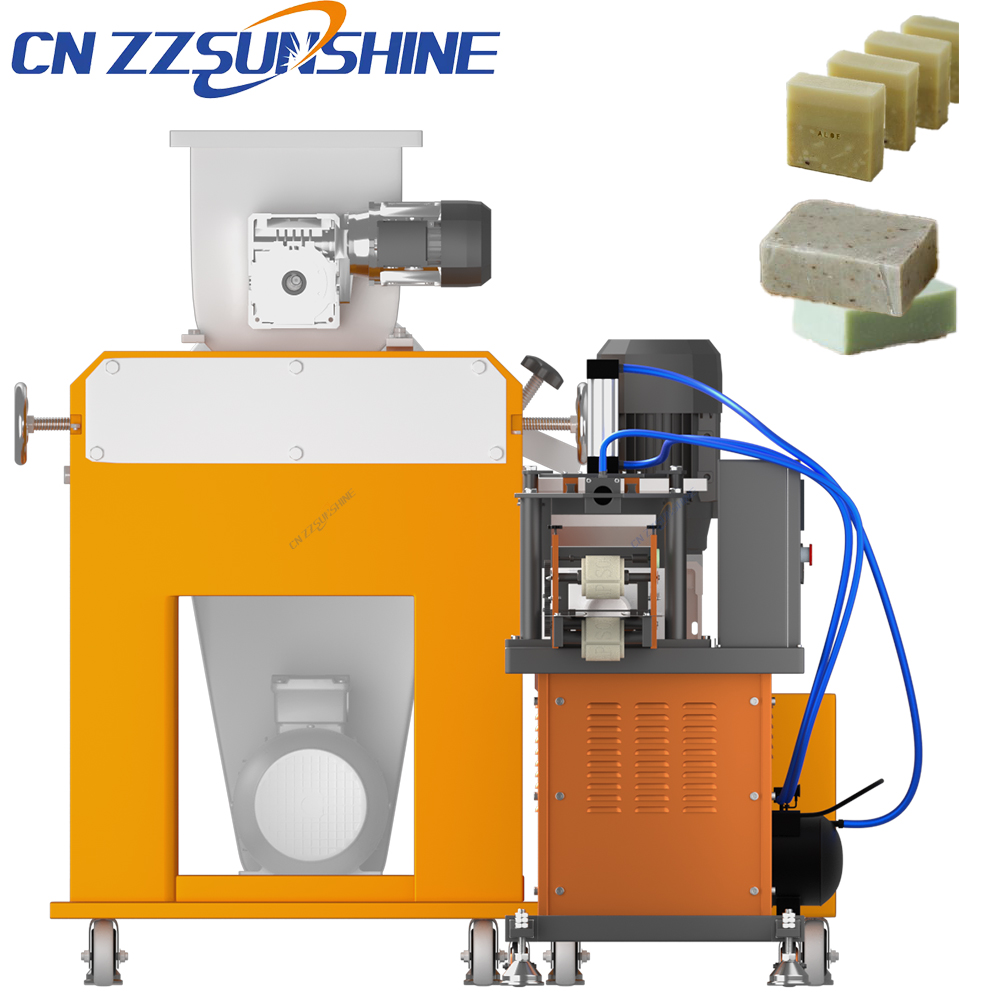

2. The Soap Plodder: Acting like a giant extruder, the soap plodder machine (often a vacuum plodder) takes the mixed soap mass and compresses it. It removes trapped air (critical for a smooth, dense bar) and forms a continuous, uniform soap noodle or log. Vacuum plodders are particularly valued for producing high-density, high-quality bars suitable for both laundry bar soap production lines and premium toilet soap finishing lines.

3. Cutting Precision: Transforming the continuous soap log into individual bars demands accuracy. Automatic block cutter machines are essential here. Options range from electronic cutting machines offering programmable precision to pneumatic cutting machines known for their robust reliability. This step eliminates the inconsistency and safety concerns associated with manual cutting machines.

Completing Your Automated Line

A truly automatic soap production line integrates these core machines with other vital components:

Refiners: Equipment like an OEM three roller grinding mill can be incorporated to refine the soap paste before plodding, ensuring an ultra-smooth texture, especially important for beauty soap making lines.

Stamping/Branding: As mentioned, the Automatic Soap Printer or Soap Stamping Machine provides the final branding touch.

Packaging: Downstream, film packaging machines efficiently wrap the finished bars for retail.

Why Automation Wins: The Tangible Benefits

Investing in a fully automatic soap production line, featuring core technologies like the Automatic Printer, Solid Soap Production Machines, and Electric Heating Mixing machine, delivers undeniable advantages:

Massive Output Increase: Automating mixing, refining, plodding, cutting, and printing dramatically boosts production capacity.

Unmatched Consistency: Machines deliver uniformity in bar weight, size, density, and print quality impossible to achieve manually.

Significant Labor Cost Reduction: Automation drastically reduces the manpower needed for strenuous tasks like cutting and stamping.

Enhanced Safety: Minimizing direct handling of materials and blades improves workplace safety.

Lower Operational Costs: While the initial investment is higher, the long-term savings in labor, waste reduction, and efficiency make automation highly cost-effective.

Scalability: From mini soap production lines for startups to large-scale laundry soap making lines, automated solutions can be tailored to your specific output needs.

The Future is Automated

For serious soap manufacturers, embracing automation is key to staying competitive. The integration of a Fully Automatic Soap Printer, robust Solid Soap Production Machines (including plodders and custom soap cutting machines), and efficient Mixing Machines with Electric Heating creates a powerhouse production line. This technology streamlines operations, ensures top-tier product quality, and unlocks significant growth potential. Explore the possibilities of an Automatic Soap Production Line today and transform the way you make soap.