The Compact Powerhouse: Your Essential Small Soap Production Line for Thriving in 2025

The demand for unique, high-quality soaps – from luxurious bath bars to effective laundry blocks – is booming, especially from boutique brands and smaller manufacturers. But scaling production efficiently without massive capital investment is a common hurdle. Enter the game-changer: the versatile Small Soap All-In-One Machine or compact Mini Soap Production Line. These integrated systems are revolutionizing soap making for small venues and are poised to be the Super Hot Soap Production Line solution of 2025, offering unparalleled flexibility and efficiency.

Why Small Venues Need Integrated Solutions

Operating in limited space doesn’t mean compromising on quality or output. Traditional large-scale soap making production lines are often impractical. Small businesses need equipment that is:

1. Space-Efficient: Compact footprints are crucial.

2. Versatile: Capable of handling various recipes (toilet, beauty, laundry bar soap) without constant reconfiguration.

3. Cost-Effective: Lower initial investment and operational costs.

4. User-Friendly: Operable with minimal specialized training.

A well-designed Automatic soap production line for small-scale operation addresses all these needs. It typically integrates core functions into a streamlined flow.

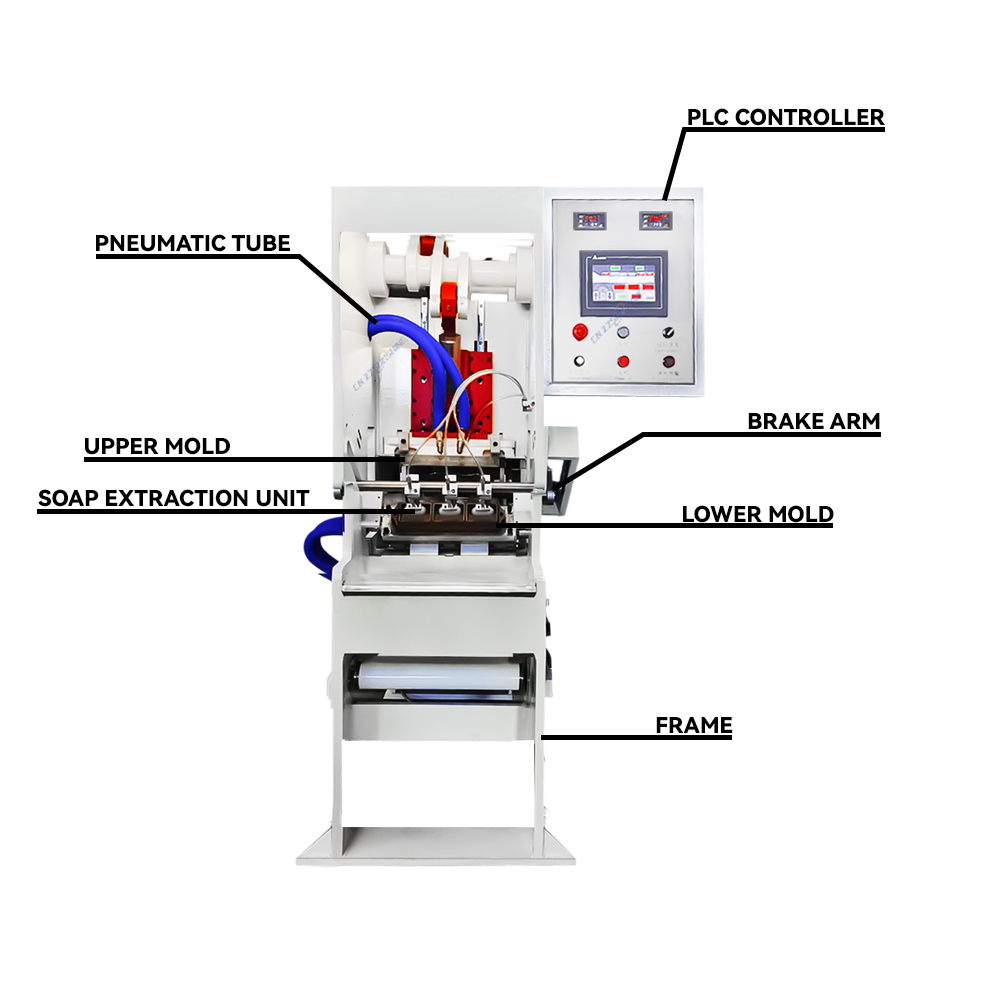

Core Components of an Efficient Small Line

While configurations vary based on specific needs (e.g., beauty soap making line vs. laundry bar soap production line), a robust mini-line often includes:

1. The Mixing Heart: A robust soap mixer or Mixing machine ensures thorough blending of oils, lye, fragrances, and additives, forming the critical soap base. This is fundamental for consistent quality.

2. Refining & Homogenizing: For premium bars, an OEM three roller grinding mill refines the soap base, creating a smooth texture and enhancing quality.

3. Extrusion & Forming: A soap plodder machine for bar soap, often a compact Vacuum plodder, is key. It extrudes the mixed soap mass under vacuum, removing air pockets for a denser, longer-lasting bar, and shapes it into a continuous log.

4. Precision Cutting: This is where flexibility shines. The line might incorporate an automatic block cutter machine for high-volume uniform bars, a custom soap cutting machine for unique shapes/sizes, or options like Manual Cutting Machine, Electronic Cutting Machine, or Pneumatic Cutting Machine depending on required automation level and precision.

5. Finishing Touches: Depending on the product (toilet soap finishing line requirements differ from laundry soap), downstream equipment might include a Semi-automatic Printer or Automatic Printer for branding, a Soap Stamping Machine for logos, and a Film Packaging Machine for attractive, protective wrapping. Some lines might also integrate simple Washing Liquid Production Equipment modules for diversification.

The All-In-One Advantage: Efficiency Unleashed

The beauty of an integrated Small Soap All-In-One Machine lies in its seamless workflow. Moving from mixing to extrusion, cutting, and potentially stamping/packaging within one compact system drastically reduces:

Labor: Minimizes manual handling between stages.

Time: Accelerates the entire production cycle.

Waste: Improves material yield and reduces errors.

Space: Eliminates the need for multiple standalone machines.

An Electric washing soap cutter integrated within such a line exemplifies this efficiency, automating a crucial step with precision.

Customization: Tailoring Your Success

No two soap businesses are identical. The best soap making machine suppliers understand this. Look for providers offering custom soap cutting machine options and flexibility in line configuration. Whether you focus on bath soap making machine outputs, intricate beauty soap making line products, or robust laundry soap making line bars, the equipment should adapt to your recipes and branding needs. OEM components like specialized rollers or cutters can make all the difference.

2025: The Rise of the Smart, Compact Producer

As we look towards 2025, the trends are clear: consumers crave artisanal quality and unique products, often from smaller, local brands. The Super Hot Soap Production Line won’t necessarily be the largest; it will be the smartest and most adaptable. Investing in a reliable, efficient Automatic soap production line designed for smaller scales is an investment in agility and competitiveness. These lines allow producers to:

Respond Quickly: Pivot to market trends with shorter production runs of diverse products.

Maintain Quality: Ensure consistent, high-grade bars with controlled processes.

Optimize Costs: Achieve excellent ROI with lower overheads.

Scale Sustainably: Grow production incrementally as demand increases.

Embrace the Future of Small-Scale Soap Making

Don’t let space or budget constraints limit your soap-making ambitions. The sophisticated Small Soap All-In-One Machine and Mini Soap Production Line solutions available today are powerful, efficient, and designed for success. By integrating essential processes like mixing, refining (with tools like the OEM three roller grinding mill), vacuum plodding, and versatile cutting (from automatic block cutter machine to custom solutions), these compact lines empower small venues to produce professional-grade soap competitively. As the demand for specialty soaps surges, positioning your business with the right, adaptable production technology is key to becoming a Super Hot contender in the 2025 marketplace. Explore the possibilities of a tailored small soap line today.