Crafting Excellence: Your Complete Guide to Integrated Soap Production Lines

For manufacturers aiming to produce high-quality solid toilet, bath, or laundry bar soaps efficiently, investing in a well-integrated production line is paramount. Such a system seamlessly combines various specialized machines, transforming raw materials into finished, market-ready products. A core component of any robust soap making production line is the sophisticated mixing stage. This involves dedicated Mixing machines, often including tanks equipped with powerful homogenizers, designed to handle the critical blending of oil, caustic soda, and other liquid components. Achieving a perfectly emulsified and uniform soap base at this initial phase is fundamental for the quality of the final bar.

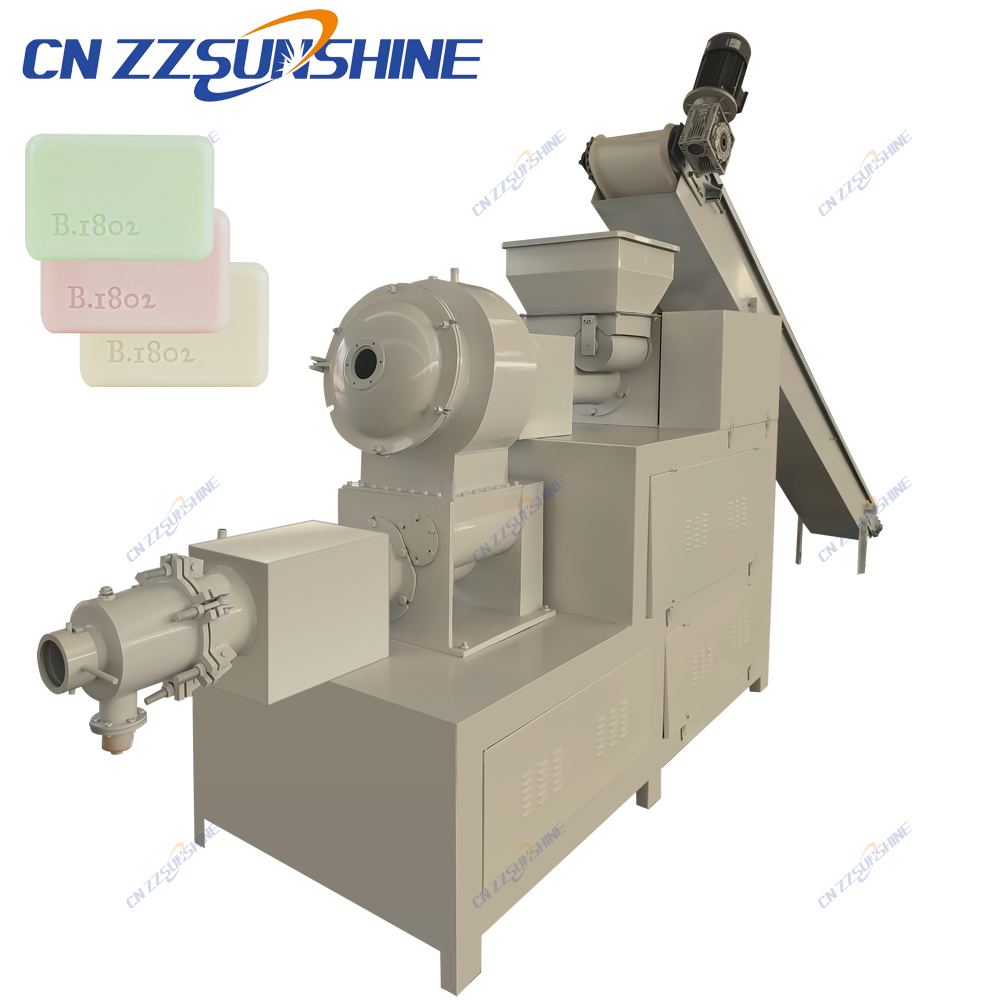

Once the soap mixture reaches the desired consistency, the process moves to refining and forming. This is where machines like the soap plodder machine for bar soap, particularly a vacuum plodder, become essential. The plodder compresses the soap mass, removing air pockets and ensuring density, while also shaping it into a continuous log or billet ready for cutting. Following extrusion, precision cutters take centre stage. An automatic block cutter machine or an Electric washing soap cutter efficiently slices the soap log into individual, uniform blocks. For operations seeking flexibility, manual cutting machines, pneumatic cutting machines, or electronic cutting machines offer different levels of automation and control.

The final stages of a toilet soap finishing line or laundry bar soap production line focus on branding and packaging. A soap stamping machine imparts the desired logo or design onto each bar. Subsequently, a film packaging machine wraps the finished soaps securely, preparing them for distribution. Whether you require a large-scale automatic soap production line, a more compact mini soap production line, or a semi-automatic printer solution, selecting equipment like a reliable soap plodder, efficient soap mixer, or OEM three roller grinding mill ensures consistent, high-volume output. Partnering with experts who offer custom soap cutting machine capabilities and tailored configurations guarantees your bath soap making machine line meets your specific production goals, helping you deliver superior products to the market efficiently. Choose a soap making machine supplier that understands the intricacies of washing liquid production equipment integration for a truly optimized operation.