Unlocking Efficiency: Your Guide to Small-Scale Automated Soap Making Lines from China

For entrepreneurs and small to medium-sized businesses venturing into the production of solid glycerin toilet soaps and laundry bars, investing in the right machinery is crucial. Finding equipment that balances affordability with reliable automation can significantly boost productivity and product consistency. This is where exploring small, automated soap making lines from China presents a compelling opportunity.

China has emerged as a global leader in manufacturing cost-effective yet technologically advanced soap production machinery. Suppliers cater specifically to the needs of smaller operations, offering compact lines designed for efficiency without the hefty price tag of large-scale industrial setups. These lines typically integrate core processes seamlessly.

At the heart lies the soap mixer or mixing machine, responsible for thoroughly blending raw materials like oils, glycerin, lye, and additives to form the soap base. Following this, a compact soap plodder machine, often a vacuum plodder, becomes essential. This unit refines the mixed soap mass, removing air bubbles and homogenizing the texture under vacuum pressure. It’s a critical step for ensuring the density and smooth finish expected of quality bar soap, whether for toilet soap finishing lines or laundry bar soap production lines.

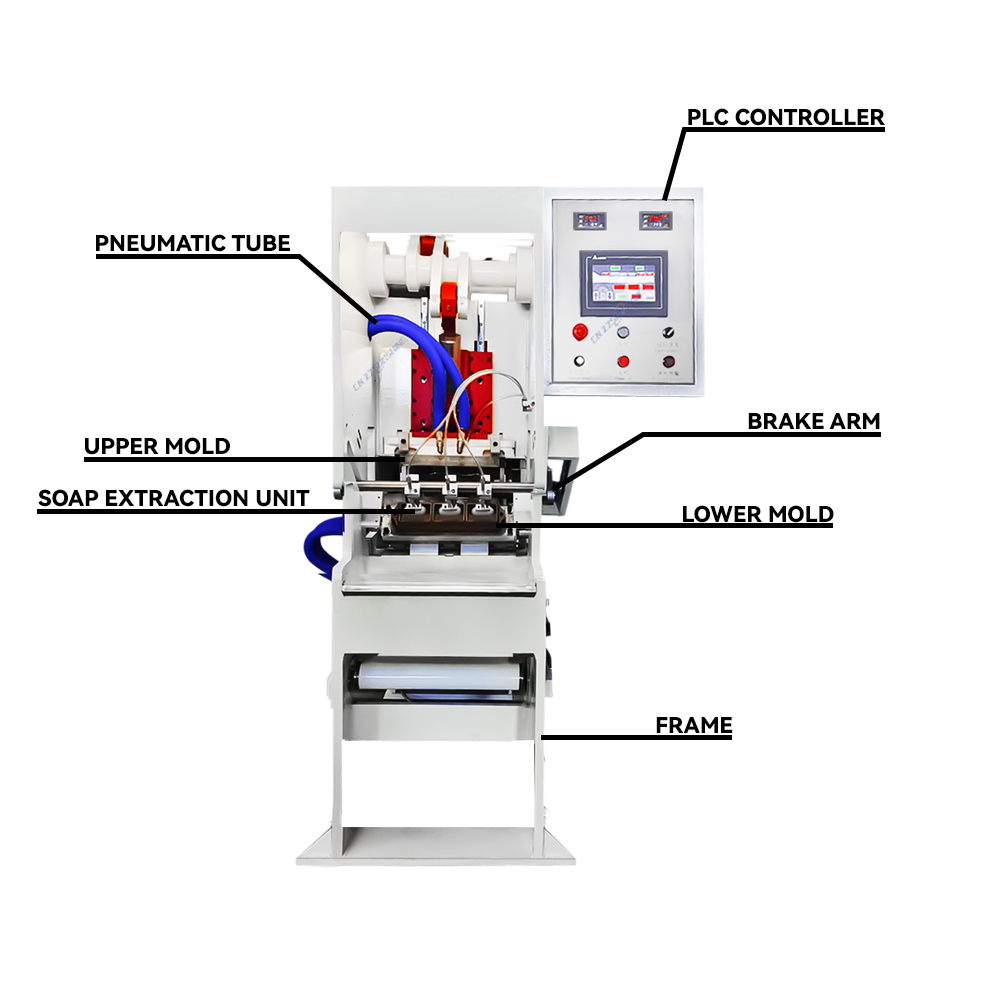

The refined soap log then moves to cutting. Options range from manual cutting machines for very low volume starts to more efficient pneumatic cutting machines or electronic cutting machines. For higher throughput, an automatic block cutter machine or a custom soap cutting machine can precisely size the soap into individual bars or billets ready for stamping. The soap stamping machine then imprints logos or designs, adding brand identity. Finally, a film packaging machine wraps the finished bars for hygiene and presentation.

Beyond the core line, auxiliary equipment like an OEM three roller grinding mill might be used for specific formulations. Suppliers often provide flexibility, offering mini soap production line configurations or semi-automatic options where certain steps like stamping (semi-automatic printer) remain manual, optimizing the investment.

The key advantage of sourcing from China lies in the combination of advanced engineering and competitive pricing. Chinese manufacturers understand the requirements for robust soap making machines suitable for bath soap making machines, beauty soap making lines, and functional laundry bars. They offer solutions that automate critical steps, reducing labor costs and minimizing human error, thereby enhancing product uniformity. Whether you need a dedicated laundry soap making line or a versatile unit for glycerin-based toilet soaps, options are available.

When evaluating the price for a small automate solid glycerin toilet laundry bar soap making machine from China, consider the specific configuration, level of automation (from semi-auto to automatic soap production line), and included equipment (like an automatic printer). Reputable suppliers provide detailed quotations based on your exact output needs and desired features. The investment delivers through improved efficiency, consistent quality, and scalability – empowering your soap manufacturing venture to thrive. Explore the possibilities and request quotes tailored to your production goals today.