Good Quality Automatic Digital Soap Noodles Making Laundry Soap Making Machine: Your Production Powerhouse

Ever wonder how those consistent, high-quality laundry bars get made efficiently? It often starts with a robust automatic soap production line, and a core component is a Good Quality Automatic Digital Soap Noodles Making Laundry Soap Making Machine. This machine is the heart of transforming raw soap mixtures into the perfect base for your final bars.

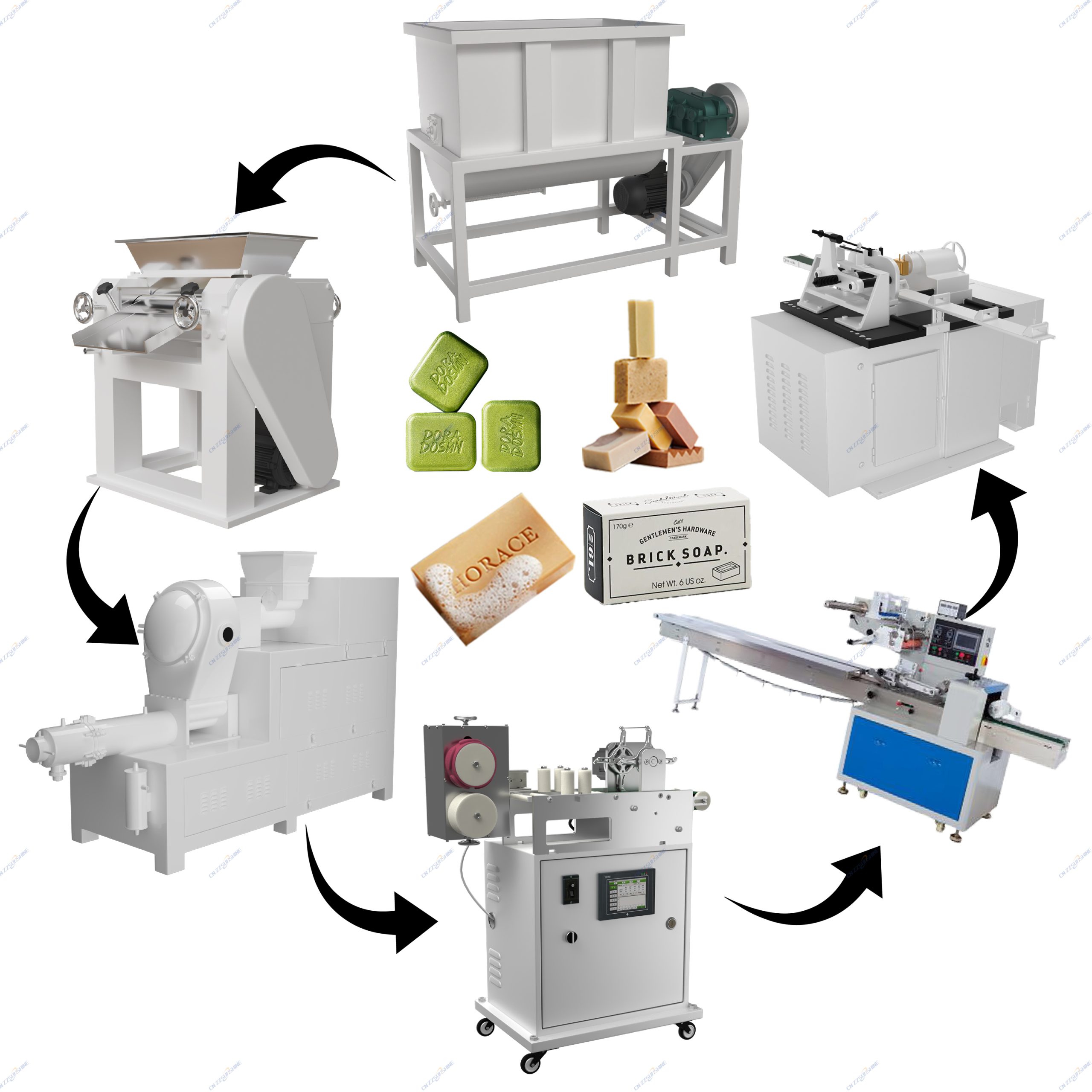

Essentially, this specialized equipment automates the critical step of producing soap noodles. It typically integrates seamlessly with other key machinery in a laundry soap making line. After the initial soap mixer or mixing machine blends the ingredients, the mixture moves into this unit. Here, advanced extrusion technology, often involving a soap plodder machine for bar soap or a Vacuum Plodder, kneads and extrudes the soap mass. The result? Uniform, continuous strands of soap noodles – the fundamental building blocks for laundry bars.

The “automatic digital” aspect signifies precision and control. Modern units often incorporate digital interfaces for setting parameters like extrusion speed and temperature, ensuring consistent noodle quality batch after batch. This consistency is vital for downstream processes.

Following noodle formation, the line typically includes drying stages and then cutting. This is where an automatic block cutter machine or a custom soap cutting machine comes into play, precisely chopping the noodles into manageable blocks or billets ready for final stamping and packaging. Machines like an Electric washing soap cutter or Pneumatic Cutting Machine offer efficient solutions here.

Integrating such an Automatic Soap Production Line significantly boosts efficiency. It reduces manual labor, minimizes waste, and ensures product uniformity – crucial for meeting market demands. Whether part of a Mini Soap Production Line or a large-scale laundry bar soap production line, this technology is indispensable. It handles the demanding nature of laundry soap production, where volume and consistency are key.

Investing in reliable soap making machinery, starting with a quality soap noodle maker, empowers manufacturers to scale operations effectively, delivering dependable laundry soap products consistently. It’s the foundation for streamlined production from boutique setups to large factories.