The Smart Choice for Small Batch Brilliance: Your Compact Soap Making Powerhouse

For passionate entrepreneurs entering the thriving world of handmade soaps, scaling production efficiently without sacrificing quality is key. You need equipment that’s adaptable, reliable, and perfectly sized for your ambitions. That’s where a versatile soap making machine designed for small businesses shines, especially one featuring a soap bomb mold capability. This isn’t just about making bars; it’s about unlocking diverse product lines with ease.

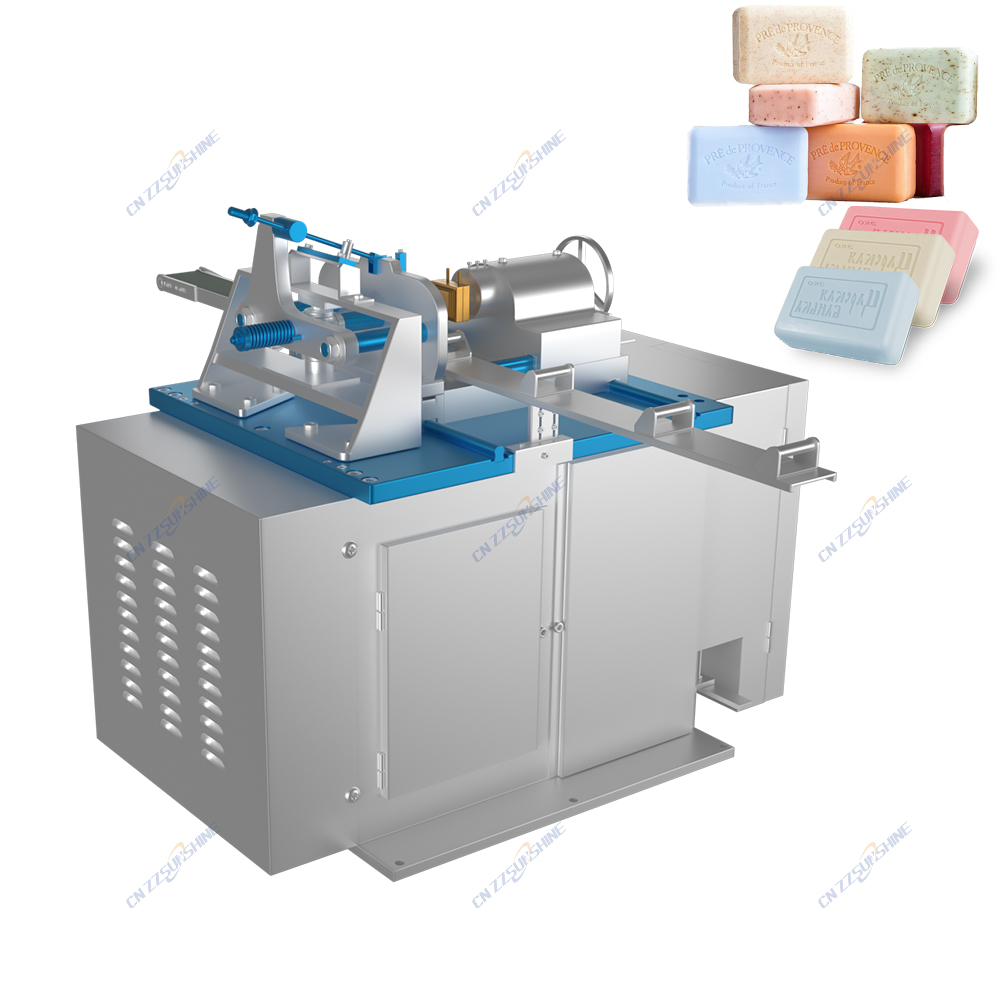

Think of your core operation. A robust soap mixer or mixing machine is your starting point, ensuring consistent blending of oils, lye, and additives for a perfect base. For refining texture and removing air bubbles crucial for a professional finish, integrating a vacuum plodder – often a compact soap plodder machine for bar soap – is essential. This step ensures your soap base is smooth, dense, and ready for the next stage.

Here’s where versatility becomes a superpower. Instead of multiple specialized machines, imagine a single soap making machine with soap bomb mold function. This intelligent design allows you to seamlessly switch between producing traditional soap bars using an integrated automatic block cutter machine or manual cutting machine and creating popular, fun soap bombs using dedicated molds. Whether you prefer the precision of an electronic cutting machine or the simplicity of a pneumatic cutting machine, having the option integrated streamlines your workflow dramatically. No need for separate, space-consuming equipment.

For businesses ready to expand their range, this core setup can be the heart of a tailored mini soap production line. Add components like a semi-automatic printer or a fully automatic printer for branding, and a soap stamping machine for those final decorative touches. A film packaging machine ensures your beautiful creations – whether classic bars or effervescent bombs – are presented professionally and protected. This creates a cohesive automatic soap production line scaled for growth.

Why choose this integrated approach?

Space & Cost Efficiency: Maximize limited workshop space and budget.

Production Flexibility: Respond quickly to market trends by easily switching between bars and bombs.

Quality Consistency: Professional-grade mixing, plodding, and cutting ensure every product meets high standards.

Scalability: Start focused and add components like printers or packagers as demand grows.

Investing in the right soap making machine is investing in your business’s future. By choosing a solution that incorporates essential functions like a soap plodder, efficient cutting (whether electric washing soap cutter, manual, or pneumatic), and crucially, the flexibility of a soap bomb mold, you empower your small business to produce diverse, high-quality products efficiently. It’s the smart foundation for building your brand in the competitive beauty and personal care market. Explore options for custom soap cutting machine integration or OEM three roller grinding mill capabilities to further refine your specific needs. Your journey from raw materials to finished, market-ready products – bars, bombs, and beyond – starts with the right compact powerhouse.