Beyond the Basics: Elevate Your Soap Production

The modern soap market demands both quality and versatility. Whether crafting specialty items like soap bombs, producing reliable hand soap, or formulating effective washing powder, the foundation lies in robust equipment and quality raw materials. Investing in the right soap making machine is crucial for efficiency and product excellence.

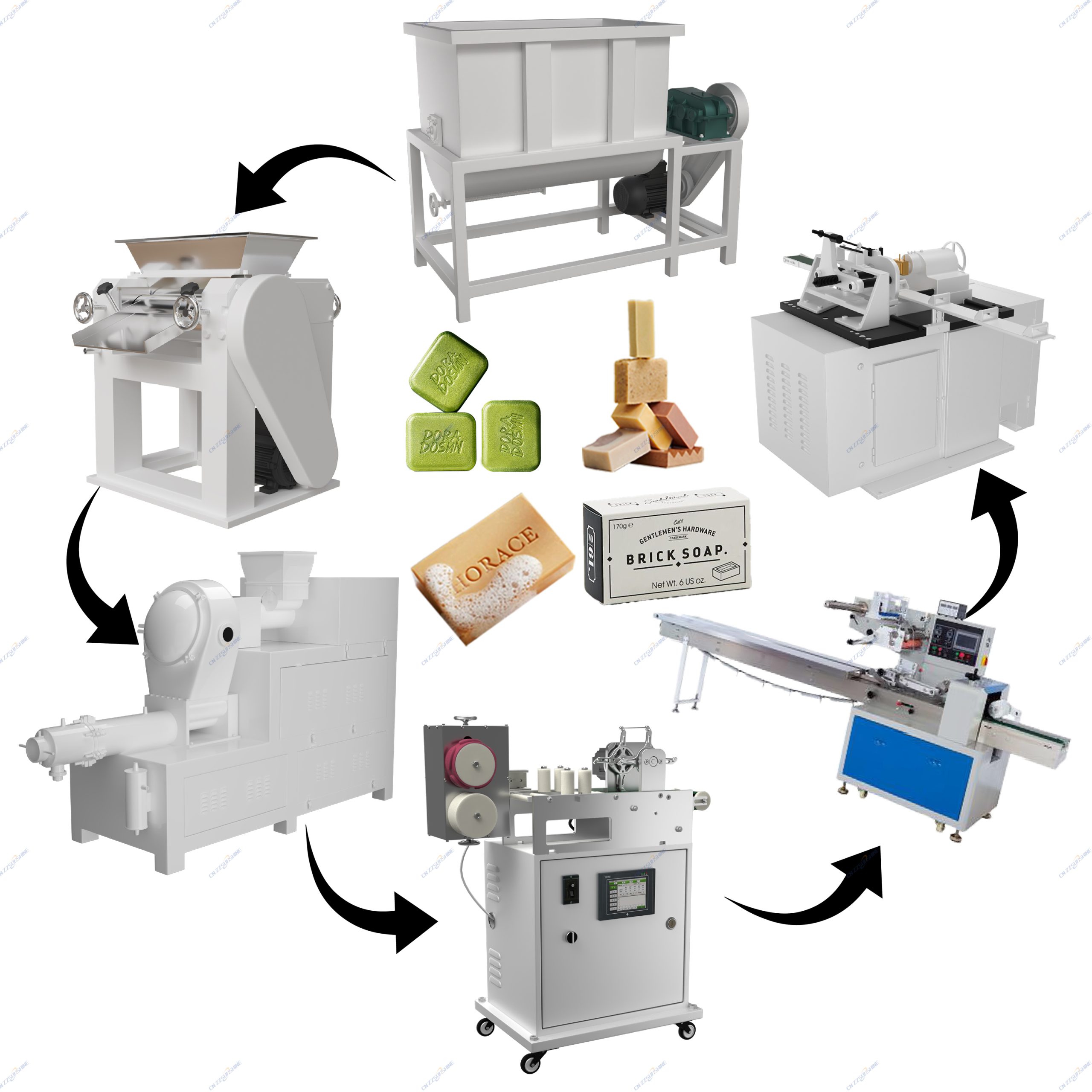

For bar soap production, a reliable soap plodder machine ensures consistent extrusion, while precise cutting – achieved with a custom soap cutting machine, be it pneumatic, electronic, or manual – guarantees uniformity. Integrating a vacuum plodder enhances bar density and longevity. Finishing touches come from a soap stamping machine, adding brand identity before the film packaging machine seals the deal.

For diverse product lines – from a laundry bar soap production line to a sophisticated beauty soap making line – selecting the appropriate soap mixer and auxiliary equipment like an OEM three roller grinding mill for refining is key. Efficient washing liquid production equipment caters to the liquid segment.

Ultimately, matching your specific needs – whether for a mini soap production line or a fully automatic soap production line – with high-grade washing powder raw material ensures you deliver superior products that stand out. The right machinery transforms raw potential into market-ready success.