The Future is Here: Super Hot Soap Production Line Innovations from China (2025)

The global demand for high-quality bar soaps, both for personal care and laundry, continues to surge. Staying competitive requires embracing cutting-edge technology. China’s soap machinery manufacturers are at the forefront, developing super hot soap production lines for 2025 that redefine efficiency and product excellence.

Modern soap making production lines, particularly those designed for laundry bar soap production line and toilet soap finishing line applications, integrate advanced automation. Key components like the vacuum plodder are essential, ensuring dense texture and eliminating air bubbles. Precision cutting is achieved with automatic block cutter machines or pneumatic cutting machines, guaranteeing uniform bar sizes crucial for branding. Downstream, soap stamping machines and film packaging machines add the final professional touches.

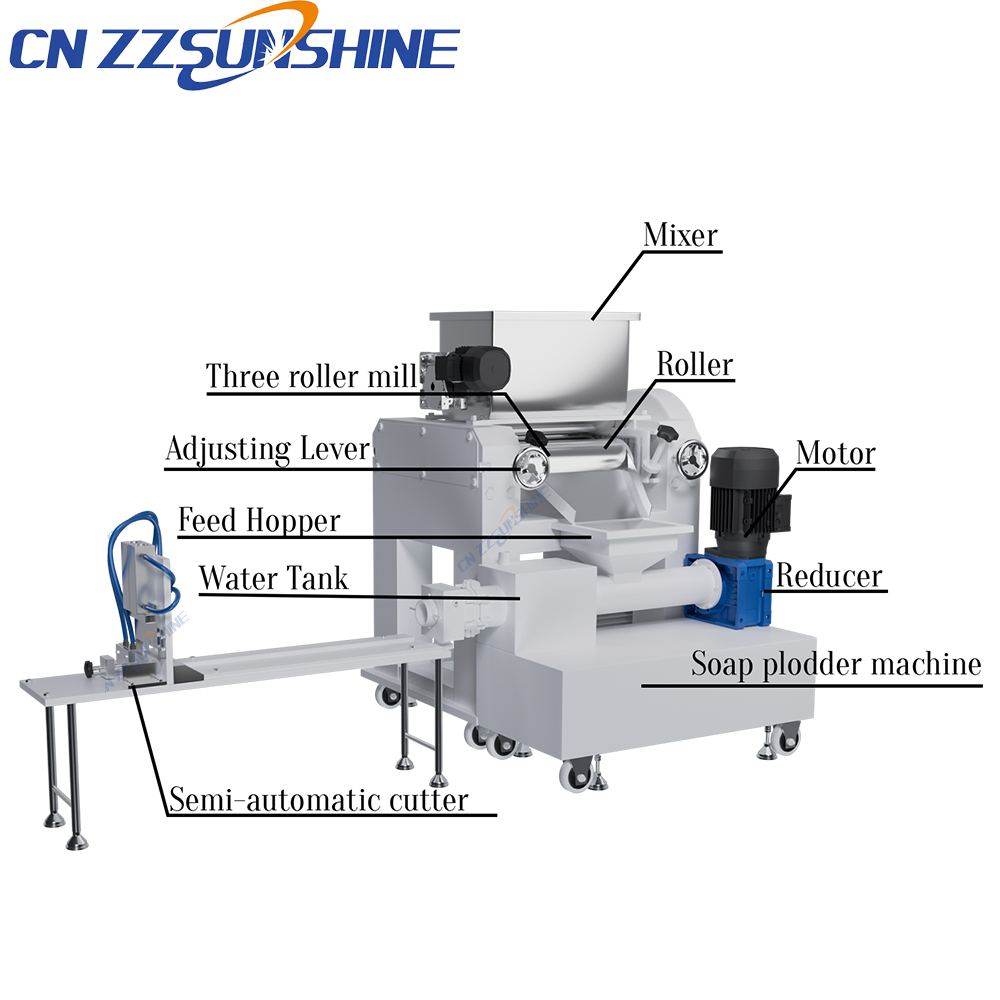

For manufacturers seeking flexibility, custom soap cutting machine solutions and mini soap production line options are increasingly popular. Whether you require a high-volume automatic soap production line or a semi-automatic printer setup, Chinese factories offer cost-efficient, reliable soap making machines. Key equipment includes robust soap plodder machines for bar soap, efficient soap mixers, and specialized three roller grinding mills for refining.

Investing in a next-generation soap factory from China means accessing customized solutions and OEM capabilities for components like OEM three roller grinding mill units. Explore how these soap production line innovations can elevate your output and quality. Contact us to find your ideal soap making machine configuration today.