Optimizing Small-Scale Soap Production: Smart Machinery Solutions

For crafters and small businesses scaling up soap production, selecting the right soap making machine is crucial. Transitioning from handcrafting requires equipment that balances efficiency with quality, without demanding excessive space or capital. A well-designed Mini Soap Production Line or Semi-automatic Printer setup can be transformative.

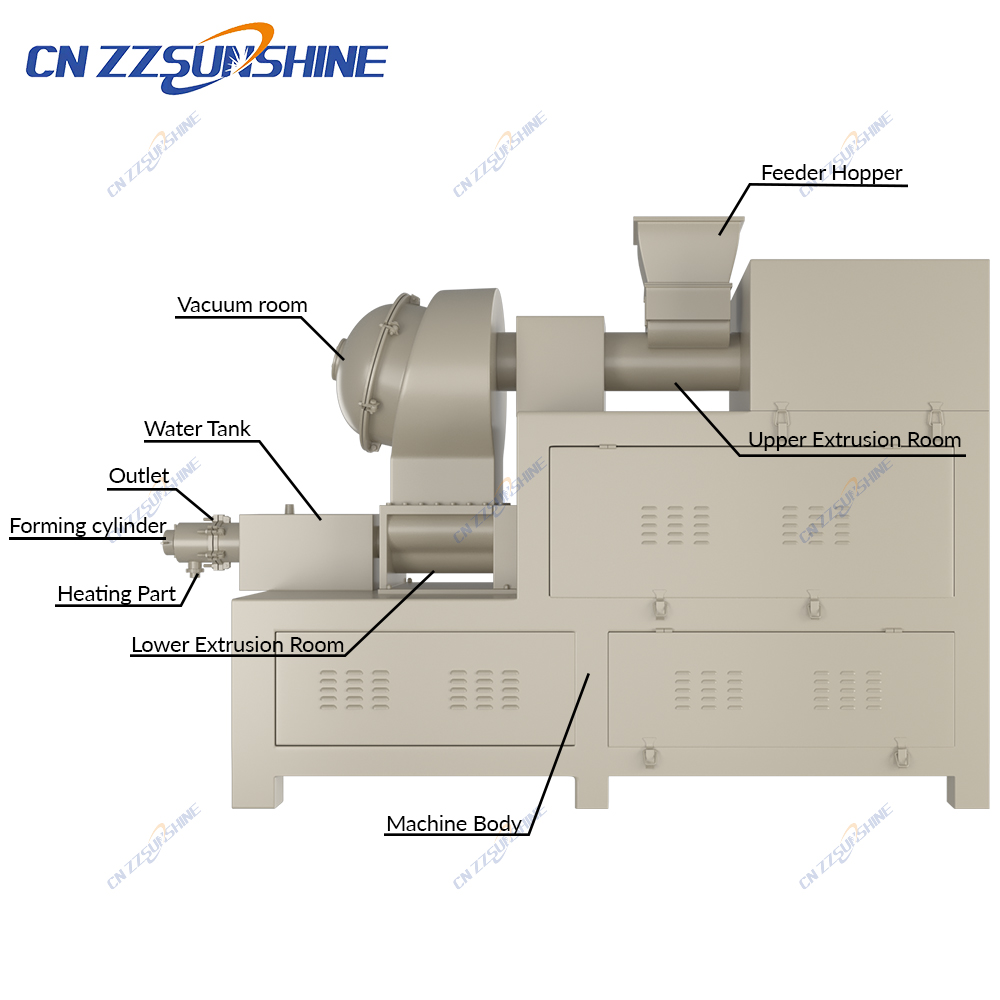

The heart of any soap making production line, be it for beauty soap making line, laundry bar soap production line, or toilet soap finishing line, lies in its core processing units. Efficient mixing machine like a soap mixer ensures homogenous blends. For solid bars, a soap plodder, especially a Vacuum plodder, is vital. It compresses and extrudes the soap base while removing air pockets, resulting in a denser, higher-quality bar. Pair this with precise cutting equipment – whether a versatile Manual Cutting Machine, a swift Pneumatic Cutting Machine, or an accurate Electronic Cutting Machine – ensures consistent sizing. An automatic block cutter machine significantly boosts output for larger batches. The OEM three roller grinding mill is key for refining paste or achieving smooth textures in specialty soaps.

Final presentation matters. Soap Stamping Machine units add branding and polish, while Film Packaging Machine options protect the finished product. Even smaller lines benefit from partial automation. Integrating a Semi-automatic Printer or Automatic Printer reduces manual handling.

Choosing equipment like a custom soap cutting machine or seeking OEM three roller grinding mill solutions allows tailoring to specific recipes and batch sizes. Investing in the right soap plodder machine for bar soap, cutter, and finishing tools within a compact Automatic soap production line framework empowers smaller producers to enhance quality, increase output, and maintain the artisanal integrity that defines their brand. What specific challenges are you facing in scaling your soap production?